Microelectroforming machine tool

An electroforming machine tool and micro-technology, applied in the direction of electroforming, electrolysis process, etc., can solve the problems of electroforming equipment that is difficult to meet the application requirements of electroforming process, the electrode configuration mode is single and unchanged, and the process effect is not good, so as to improve the reliability Controllability and ease of operation, improve the quality of electroforming process, optimize the effect of the process environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

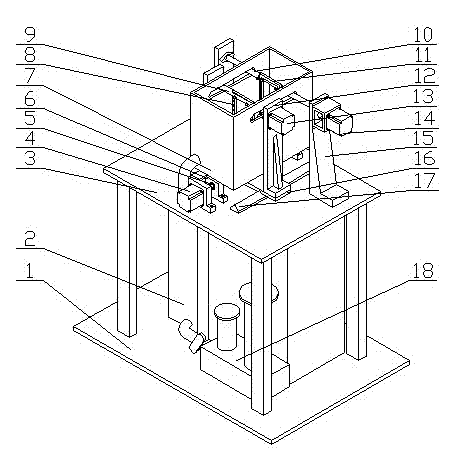

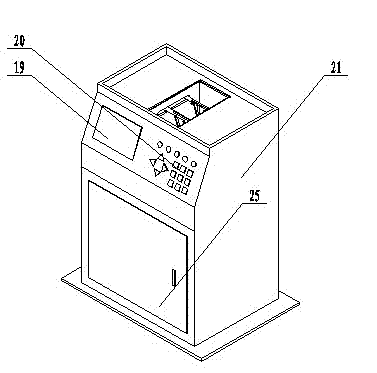

[0021] like Figures 1 to 6 As shown, the micro-electroforming machine tool includes a machine base 1, a workbench 3, an electroforming tank 7 located on the workbench 3, and an anode clamping unit and a cathode clamping unit located in the electroforming tank 7, which are located under the workbench 3 The liquid storage tank 2, the filtration circulation unit 18, the temperature control unit, the electroforming process parameter monitoring unit, in addition, the micro electroforming machine tool also includes an anode horizontal feed unit, an anode rotation unit, a cathode rotation unit and a motion control system.

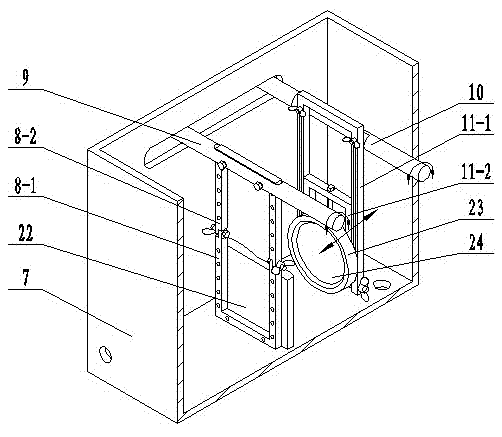

[0022] The anode clamping unit includes an anode rotating rod 9 and an anode hanger 8 installed on the anode rotating rod 9, (such as image 3 As shown) the anode hanger is formed by connecting the upper hanger 8-2 and the lower hanger 8-1 through threads, and the lower hanger 8-1 can rotate around the axis of the threaded connection relative to the upper hanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com