Brewing device by taking sweet sorghum stalks as raw materials

A sweet sorghum and raw material technology, applied in the field of alcohol or wine production equipment, can solve the problems of uncontinuous production, low alcohol output, long fermentation time, etc., and achieve the effects of easy collection and control, shortened fermentation time, and easy control of indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

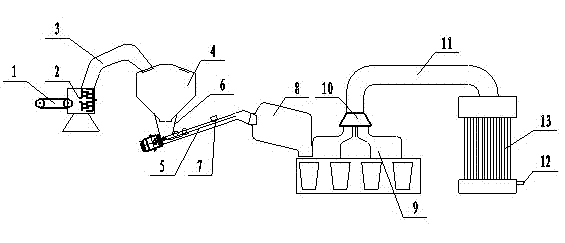

[0021] The above-mentioned equipment such as raw material conveyor, pulverizer, conveyor, solid-state fermentation tank, cooling tower are all existing known products, and its structure and working principle are well known to those of ordinary skill in the art. The conveyor is also called screw conveyor, and the rotating helical blades push and transport the materials, and can also further mix and stir the materials while conveying; the pulverizer is also called claw pulverizer, and the feed hopper The material enters the center of the crushing chamber by its own weight and negative pressure suction. Under the action of centrifugal force and airflow, it moves from the inner ring to the outer ring. Crushing, the qualified crushed material is discharged out of the machine through the sieve hole and enters the conveying pipeline; the coarse particles continue to be hit until they pass through the sieve hole.

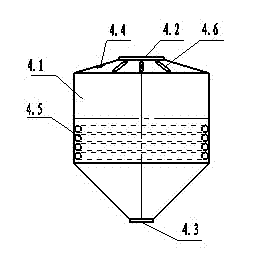

[0022] The solid-state fermentation tank is a rotary barrel-type solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com