High temperature-resistant nylon/thermotropic liquid crystal polymer blend and preparation method for blend

A liquid crystal polymer, high temperature resistant technology, applied in the polymer field, can solve the problems of high price, low mechanical properties, difficult processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

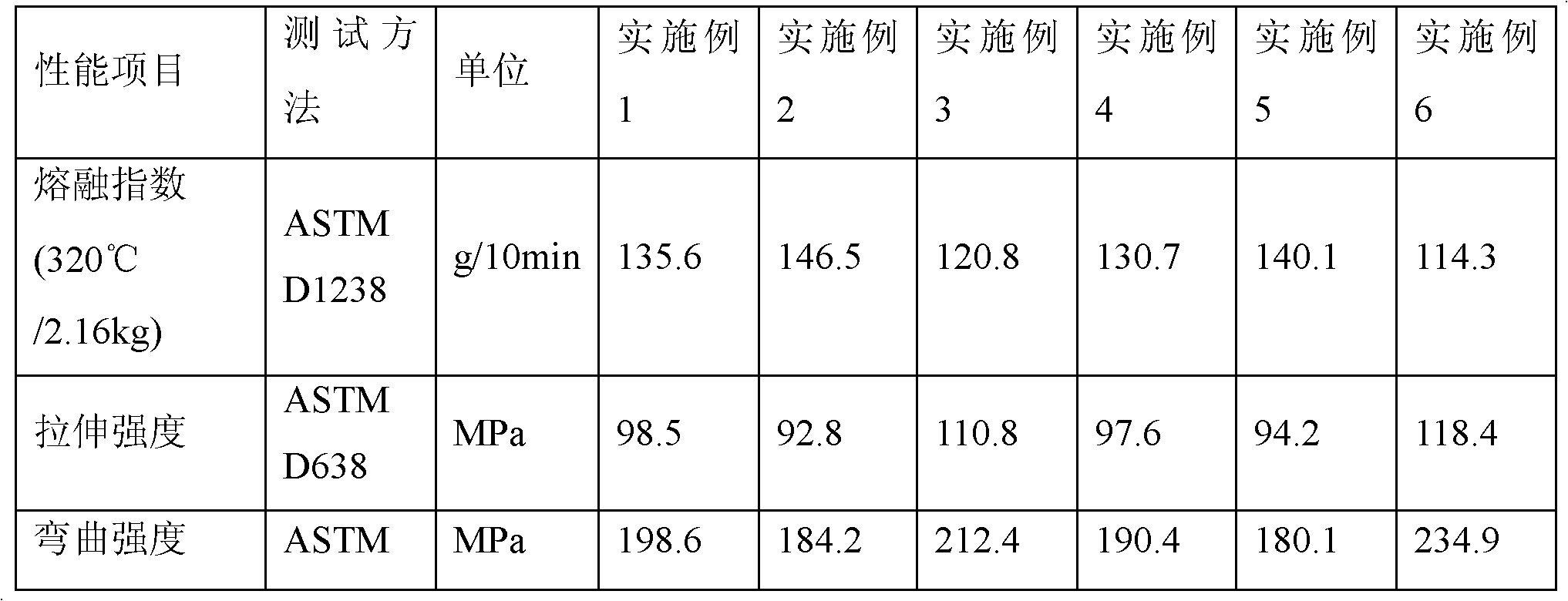

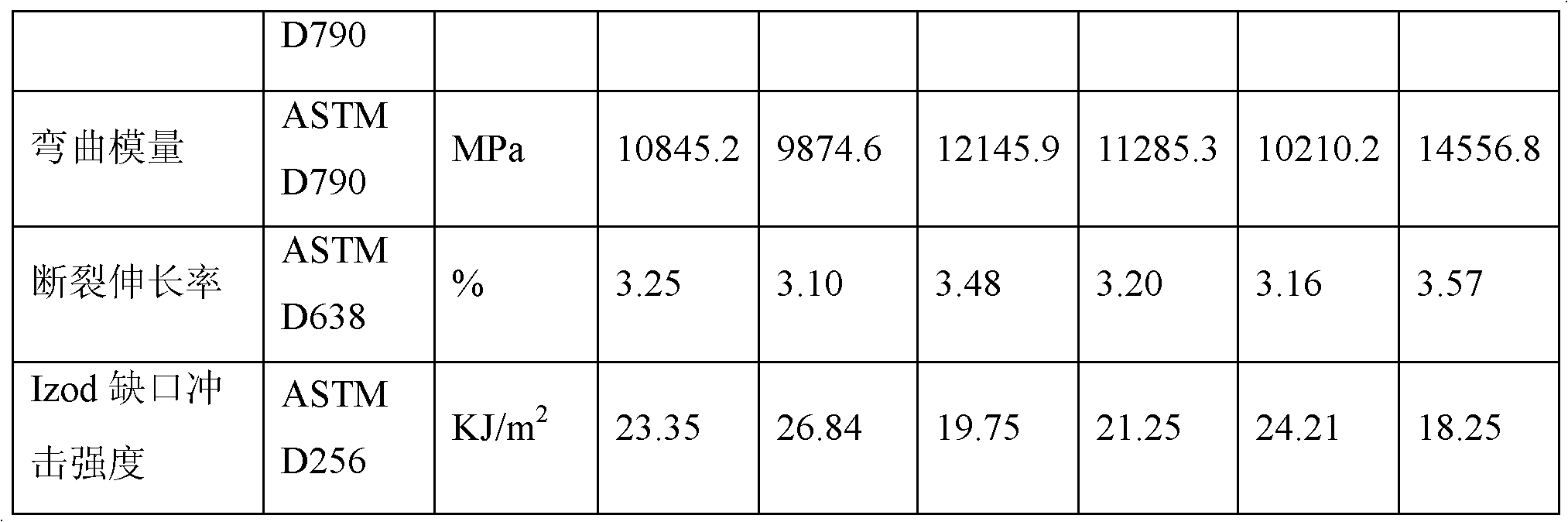

Examples

Embodiment 1

[0034] (1) Vacuum dry 80 parts of HPN at 90°C for 24 hours for later use, and dry 10 parts of TLCP at 130°C for 4 hours for later use;

[0035] (2) Take 7 parts of compatibilizer PE-g-MAH, 0.4 part of antioxidant 1098 and 0.2 part of antioxidant 168, and 0.8 part of lubricant calcium stearate to be dried separately for use;

[0036] (3) The above-mentioned components are fully mixed in a high-speed mixer;

[0037] (4) Then put it into a twin-screw extruder for extrusion granulation. The temperature of the extruder is: Zone 1 temperature: 270°C, zone 2 temperature: 285°C, zone 3 temperature: 300°C, zone 4 temperature: 310°C, zone 5 temperature: 320°C, zone 6 temperature: 300°C, zone 7 Zone temperature: 285°C, head temperature: 175°C; extrusion rate: 180r / min, residence time: 2min.

Embodiment 2

[0039] (1) Vacuum dry 70 parts of HPN at 80°C for 24 hours for later use, and dry 10 parts of TLCP at 130°C for 4 hours for later use;

[0040] (2) Take 5 parts of compatibilizer PE-g-MAH, 0.6 part of antioxidant 1098 and 0.2 part of antioxidant 168, and 0.4 part of lubricant zinc stearate and dry them separately for use;

[0041] (3) The above-mentioned components are fully mixed in a high-speed mixer;

[0042] (4) Then put it into a twin-screw extruder for extrusion granulation. The temperature of the extruder is: Zone 1 temperature: 280°C, zone 2 temperature: 290°C, zone 3 temperature: 305°C, zone 4 temperature: 315°C, zone 5 temperature: 320°C, zone 6 temperature: 310°C, zone 7 Zone temperature: 290°C, head temperature: 180°C; extrusion rate 200r / min, residence time 1min.

Embodiment 3

[0044] (1) Vacuum dry 90 parts of HPN at 100°C for 24 hours for later use, and dry 8 parts of TLCP at 130°C for 4 hours for later use;

[0045] (2) Take 5 parts of compatibilizer PE-g-MAH, 0.7 part of antioxidant 1098 and 0.1 part of antioxidant 168, and 0.2 part of lubricant calcium stearate and dry them separately for use;

[0046] (3) The above-mentioned components are fully mixed in a high-speed mixer;

[0047] (4) Then put it into a twin-screw extruder for extrusion granulation. The temperature of the extruder is: Zone 1 temperature: 270°C, zone 2 temperature: 280°C, zone 3 temperature: 300°C, zone 4 temperature: 310°C, zone 5 temperature: 320°C, zone 6 temperature: 300°C, zone 7 Zone temperature: 285°C, head temperature: 190°C; extrusion rate 150r / min, residence time 3min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com