Technology and system for treating roasted eel industrial sewage

A technology for treating process and industrial sewage, which is applied in food industry wastewater treatment, water/sewage multi-stage treatment, animal processing wastewater treatment, etc. It can solve problems such as large consumption of dissolved oxygen, high concentration of organic matter, and environmental hazards of water bodies, and achieve consumption can low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

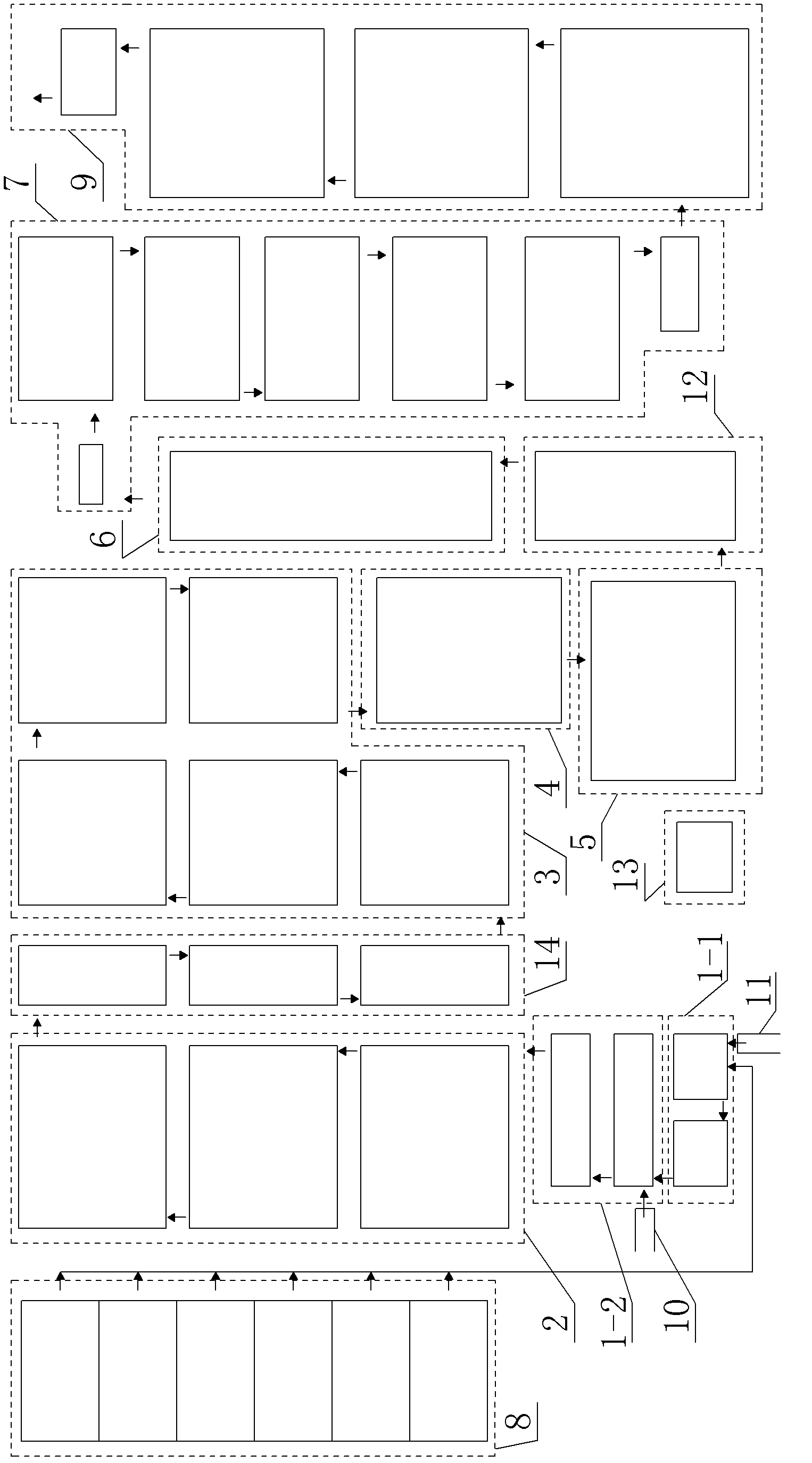

[0040] An industrial sewage treatment process for grilled eels, characterized in that the sewage is treated by the following steps in sequence:

[0041] a. Oil-separated primary sedimentation treatment: Send 400-450 tons / day of roasted eel sewage into oil-separated primary sedimentation equipment 1-1. During the production and processing process, two kinds of industrial wastewater, raw water and cooked water, are produced. The raw water is Unheated water, including killing eel sewage, boiled water is heated water including roasted eel sewage; the cooked water is sent into the oil separation equipment 1-1 with a capacity of 160 cubic meters, and at natural ambient temperature, after 13- 16 hours of oil separation and filtration to remove slick oil; send raw water and cooked water after oil separation and filtration to primary sedimentation equipment 1-2 with a capacity of 90 cubic meters, and undergo 9-13 hours of sedimentation and filtration at natural ambient temperature Remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com