Method and system for treating saline wastewater to zero discharge and recycling

A salt-containing wastewater, zero-discharge technology, applied in the field of salt-containing wastewater treatment methods and systems, can solve the problems of difficult to achieve goals, reduced evaporation efficiency, high investment and operating costs, and achieve volume reduction, efficiency improvement, and investment. and the effect of lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0059] Such as figure 1 As shown, the present invention is a method and system for treating high-salt wastewater to zero discharge and realizing separate recycling of salt and water, referred to as WLZD, which includes the following steps:

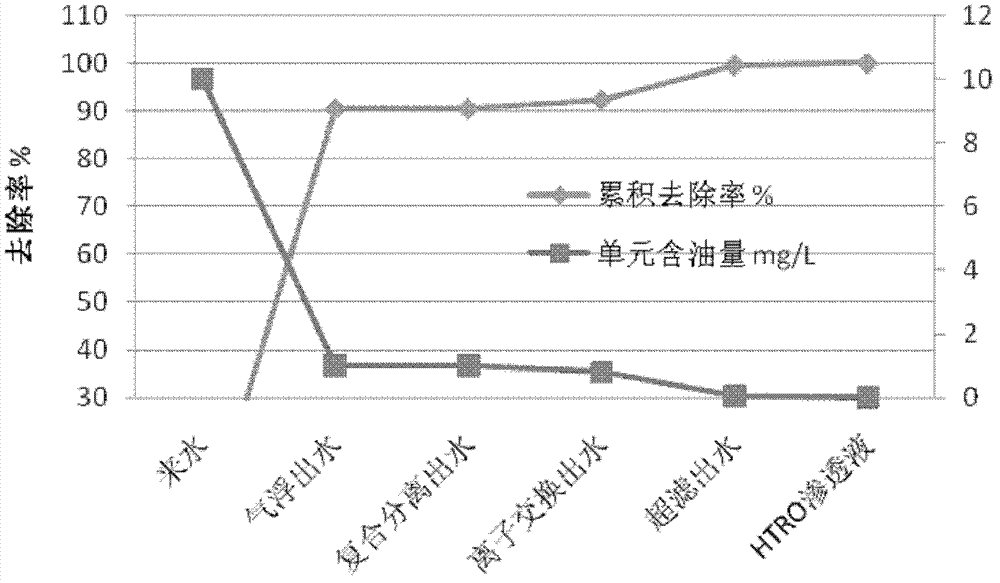

[0060] 1) The incoming water enters the adjustment tank after passing through the grille, and enters the enhanced pretreatment unit through the lift pump, referred to as WLPD, as shown in the attached Figure 12 , this unit removes suspended solids, oil, alkalinity, hardness and scaling ions in wastewater. The agents used in this unit are PAC, PAM, alkalinity remover, and ion precipitant. The dosage of PAC and PAM is 5-50mg / L and 0.5-10mg / L respectively. The alkalinity and the content of scaling ions are calculated. The air flotation adopts the dissolved air pump air flotation technology, the sediment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com