Stripping tower

A stripping tower, reaction column technology, applied in the direction of degassed water/sewage treatment, etc., can solve the problems of high concentration of organic matter and ammonia nitrogen, not well solved, poor biodegradability, etc. Simple, high impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

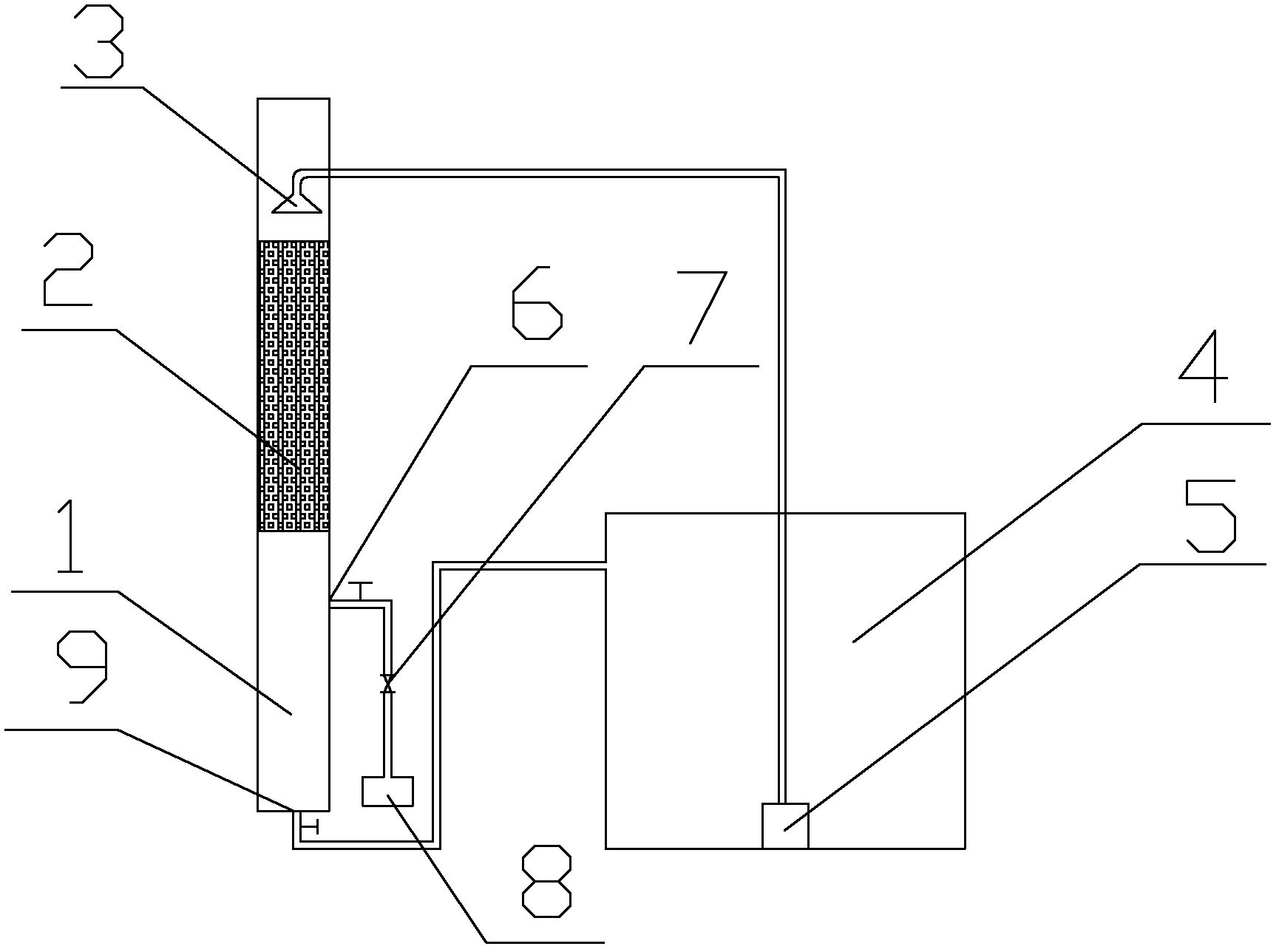

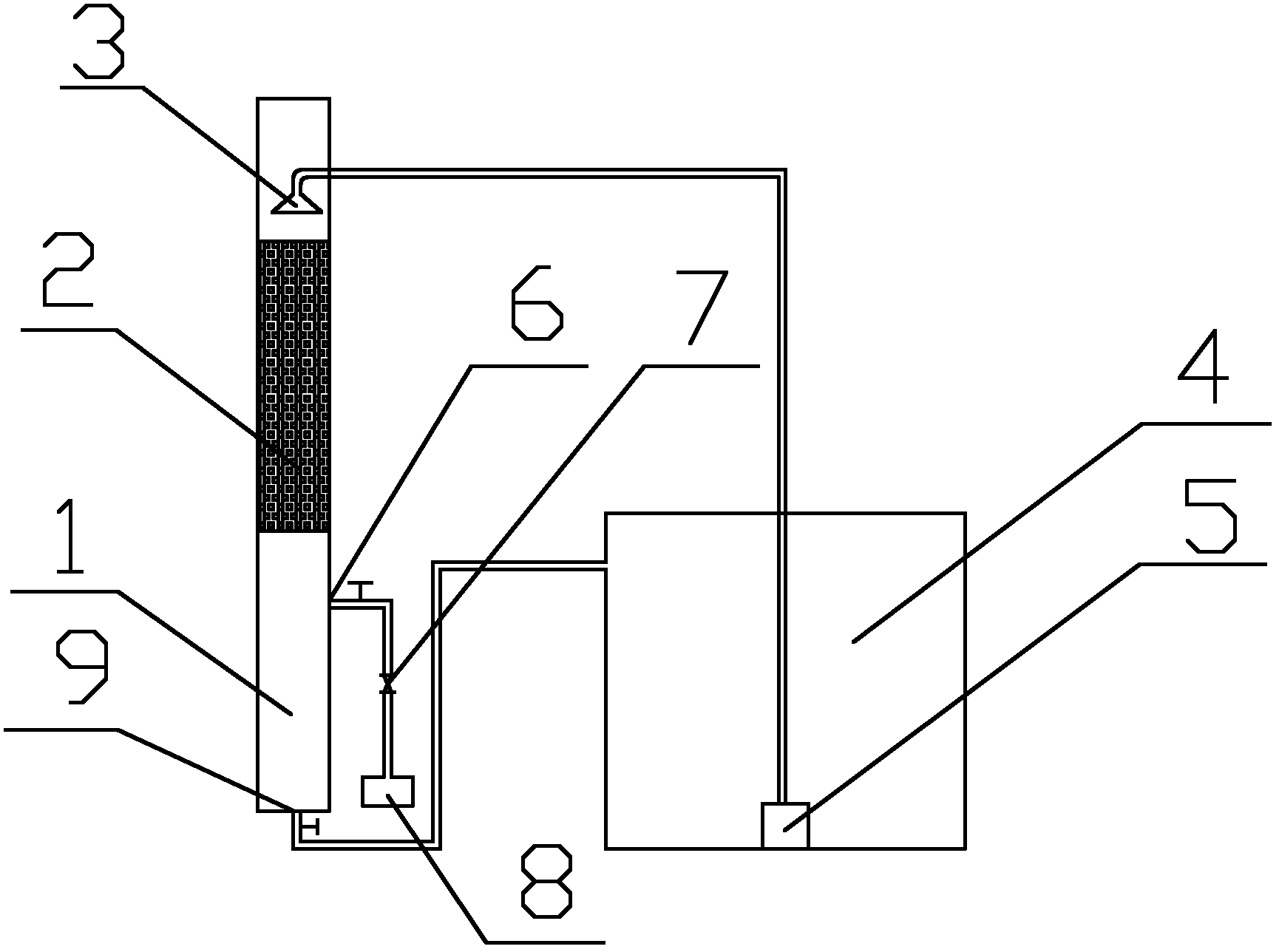

[0008] As shown in the accompanying drawing, a kind of stripping tower provided by the present invention comprises a reaction column 1, the middle part of the reaction column 1 is filled with a filler 2, and the top of the reaction column 1 is provided with a nozzle 3, and the nozzle 3 and the submersible pump in the water tank 4 5 are connected; the middle part of the reaction column 1 is provided with an air inlet 6, and the air inlet 6 is connected to the air pump 8 through the gas flow meter 7;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com