Boosting hydraulic brake master cylinder and brake system thereof

A technology of hydraulic brakes and brake systems, applied in the field of brake systems, can solve problems such as insufficient pressure, brake failure, and unsatisfactory brake effects, and achieve the effects of reducing weight, preventing deviation, and improving brake pressure and brake reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

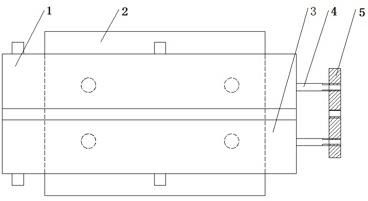

[0015] Such as figure 1 As shown, the pressurized hydraulic brake master cylinder of the present invention includes an oil pot 2 and two double-chamber hydraulic cylinders 1, 3 with the same structure and specifications arranged side by side. The oil pot 2 and two double-chamber hydraulic cylinders 1 and 3 are conjoinedly arranged. There are also two sub-push rods 4 that are respectively connected to the pistons of the two parallel conjoined double-chamber hydraulic cylinders in parallel. , to realize the synchronous work of two hydraulic cylinders. The four oil inlet holes of the two double-cavity hydraulic cylinders connected in parallel communicate with the oil pot respectively. The four oil outlet holes of the two double-cavity hydraulic cylinders connected in parallel are used to communicate with the brake cylinders.

[0016] In order to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com