Method for quick fixture positioning for numerical control machine and tool setting device

A technology of CNC machine tools and tool setting devices, applied in positioning devices, automatic control devices, feeding devices, etc., can solve the problems of complex and time-consuming, affecting the delivery cycle of parts, and high requirements for the one-time pass rate of CNC machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

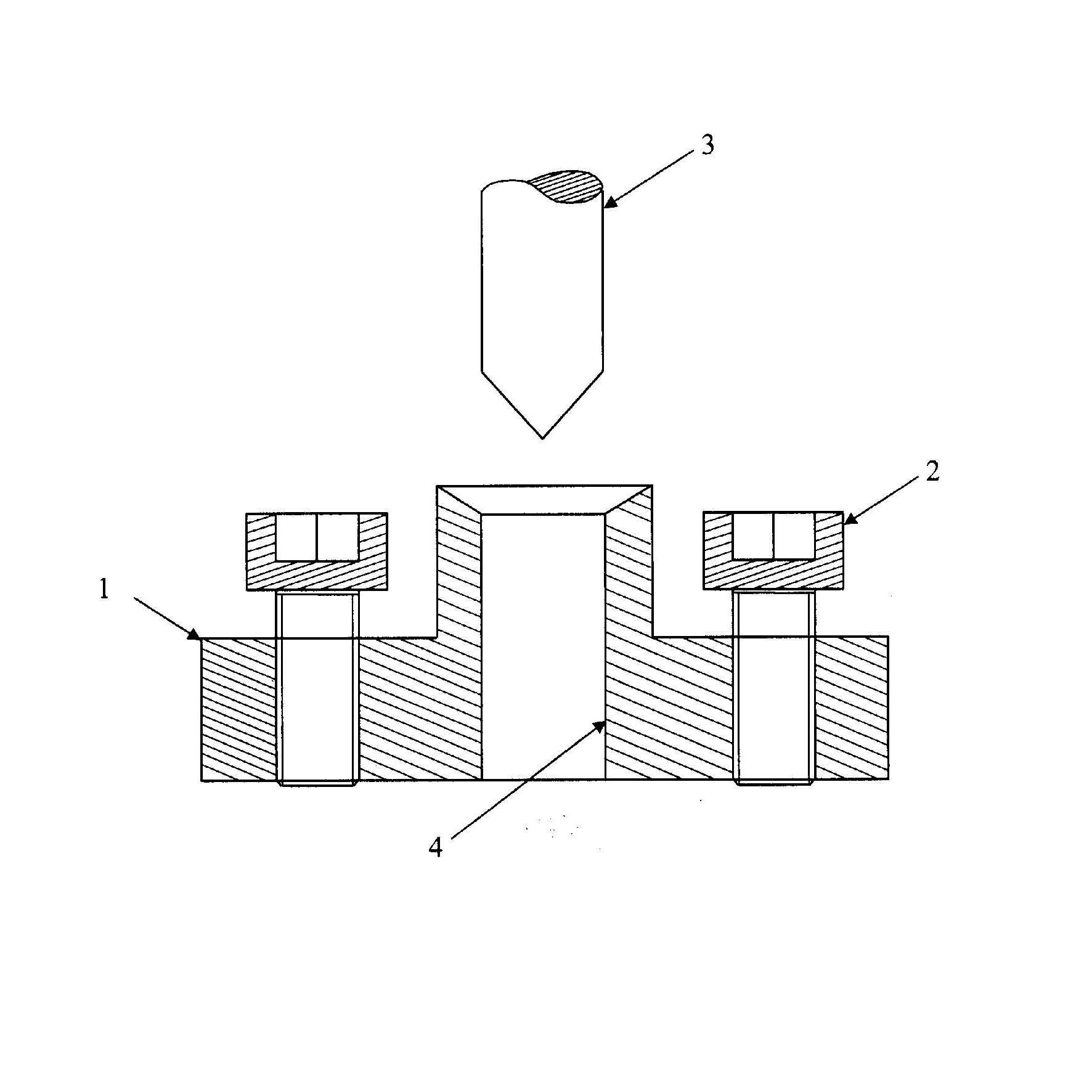

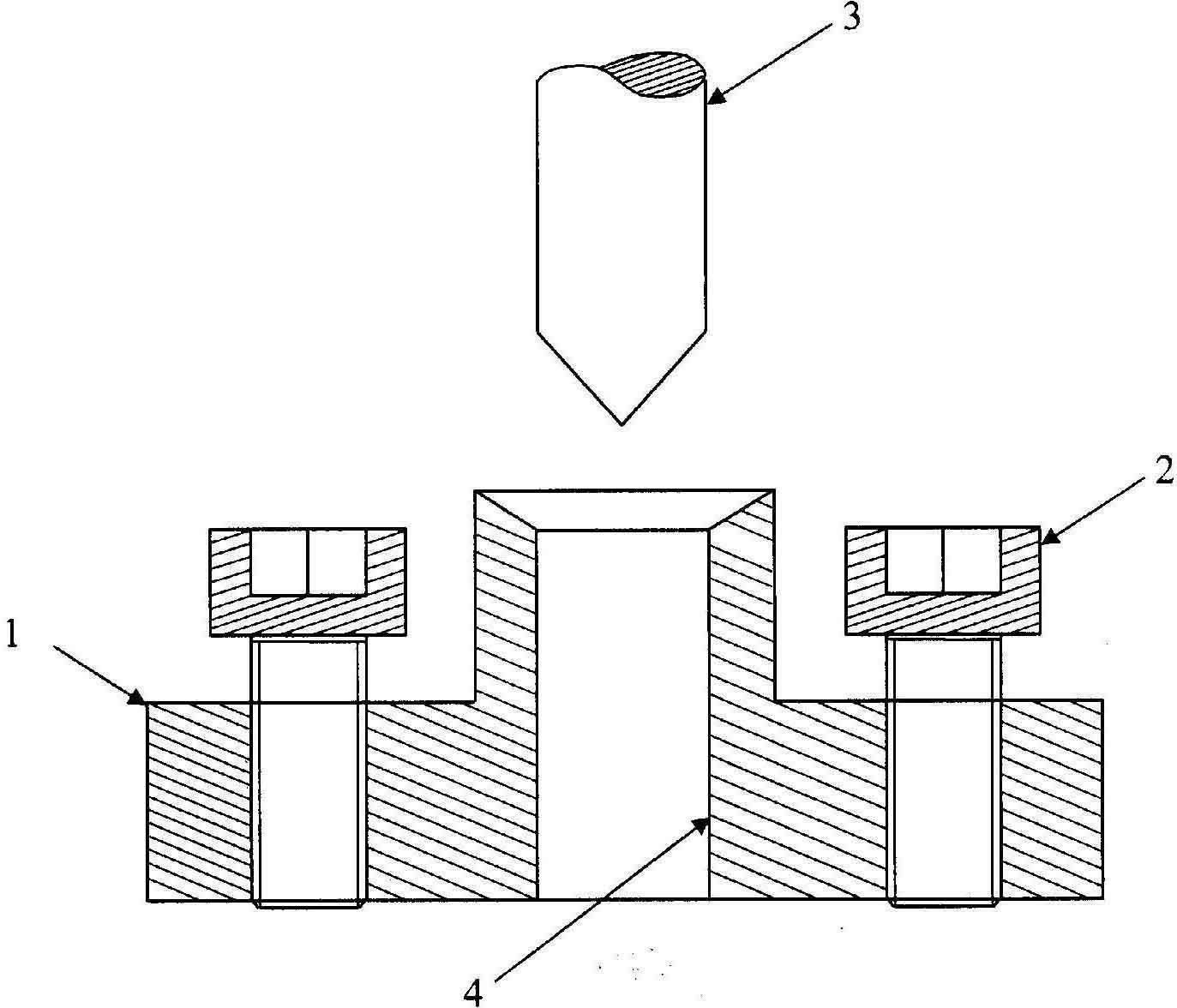

[0018] like figure 1 As shown, a tool setting device for a CNC machine tool, the center of the inverted T-shaped block 1 is a positioning hole 4, and a pin 3 is arranged in the positioning hole 4, and the diameter of the pin 3 is the same as the diameter of the positioning hole 4 Equal, the two ends of the T-shaped block 1 are symmetrically provided with fastening screws 2 .

[0019] A method for fast positioning of tooling of a numerically controlled machine tool, comprising the following steps:

[0020] 1) First drill two through holes on the tooling, record the distance between the two holes and the position coordinates of the two holes relative to the positioning reference hole of the part on the fixture;

[0021] 2) Enter the coordinate value of the width direction center position of a certain T-slot on the machine tool table into the machine tool control system and save it;

[0022] 3) Clamp the pin 3 on the spindle of the CNC machine tool, and put the two T-shaped blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com