Gapless numerical control driving mechanism of rotary table

A driving mechanism and numerical control turntable technology, applied in metal processing and other directions, can solve the problems of reduced transmission accuracy and transmission efficiency, and achieve the effect of improving the rotation accuracy and transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

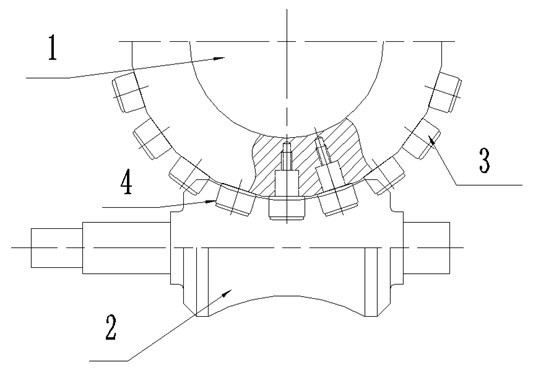

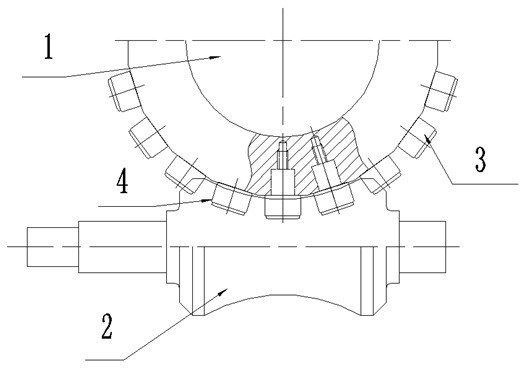

[0011] Such as figure 1 As shown, the present invention provides a gapless numerical control turntable drive mechanism. The drive mechanism includes a worm gear 1 and a worm 2 that cooperate with each other. The worm is a screw-shaped input shaft structure, and the turbine is a needle roller bearing. 3 It is a radial embedded turret structure, the turbine is in contact with the worm through a needle roller bearing, and the gapless worm and worm can be contacted with pre-compression. 4, there is no gap between the worm and worm.

[0012] The invention is composed of a turret with a screw-shaped input shaft and a needle roller bearing radially embedded. The difference from a common turbine is that the contact part with the worm is completed by a needle roller bearing, and the needle roller bearing is subjected to friction Later, it will rotate to eliminate friction and will not cause lockup. With this feature, it is not necessary to leave a gap between the traditional worm gear tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com