Reciprocating cutting tool

A technology for cutting tools and reciprocating rods, which is applied to manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve problems such as cumbersomeness, wear of positioning pins and groove edges, affecting work efficiency, etc., and achieves increased rotational resistance, The effect of increasing the rotational resistance and stabilizing the positional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

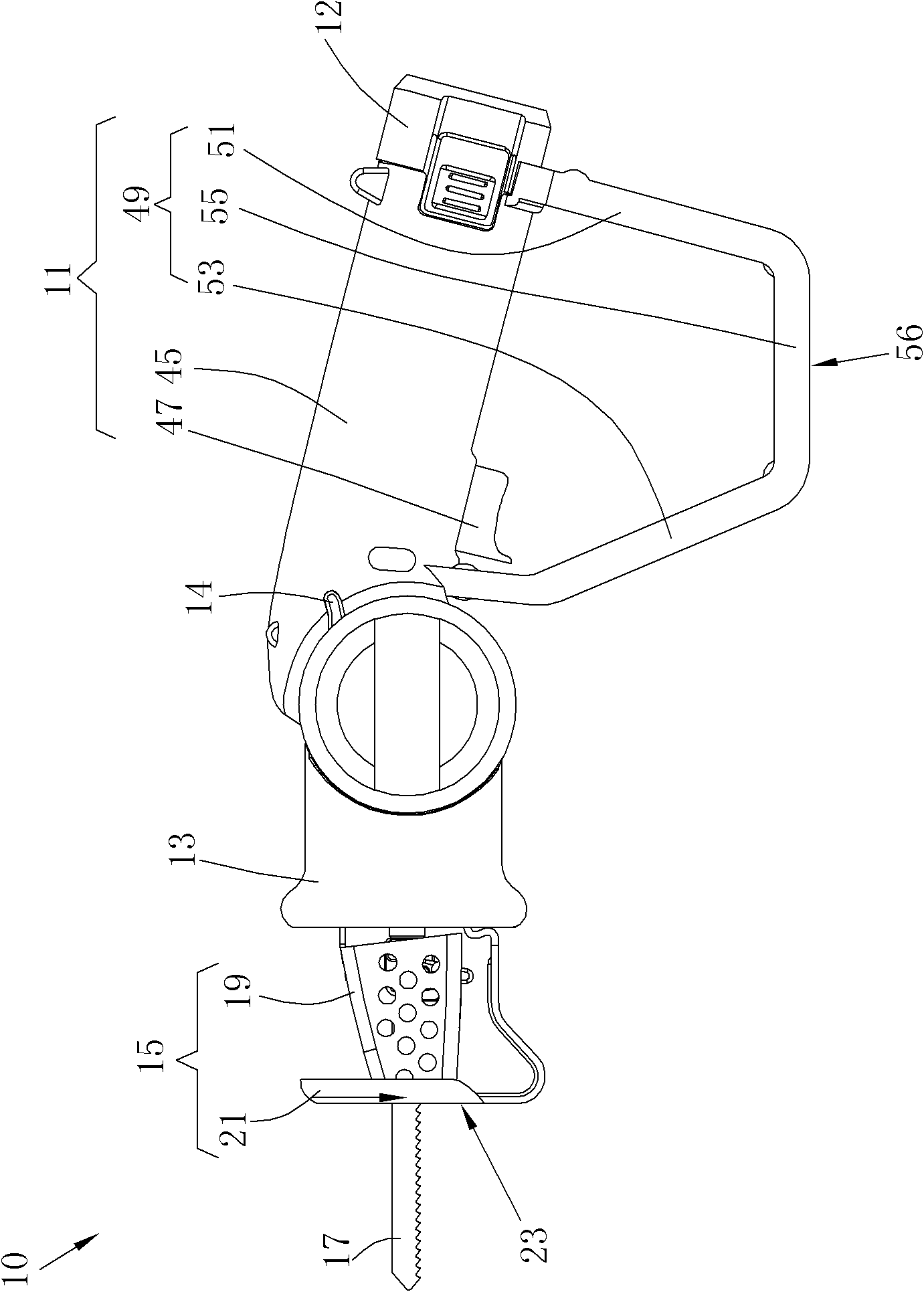

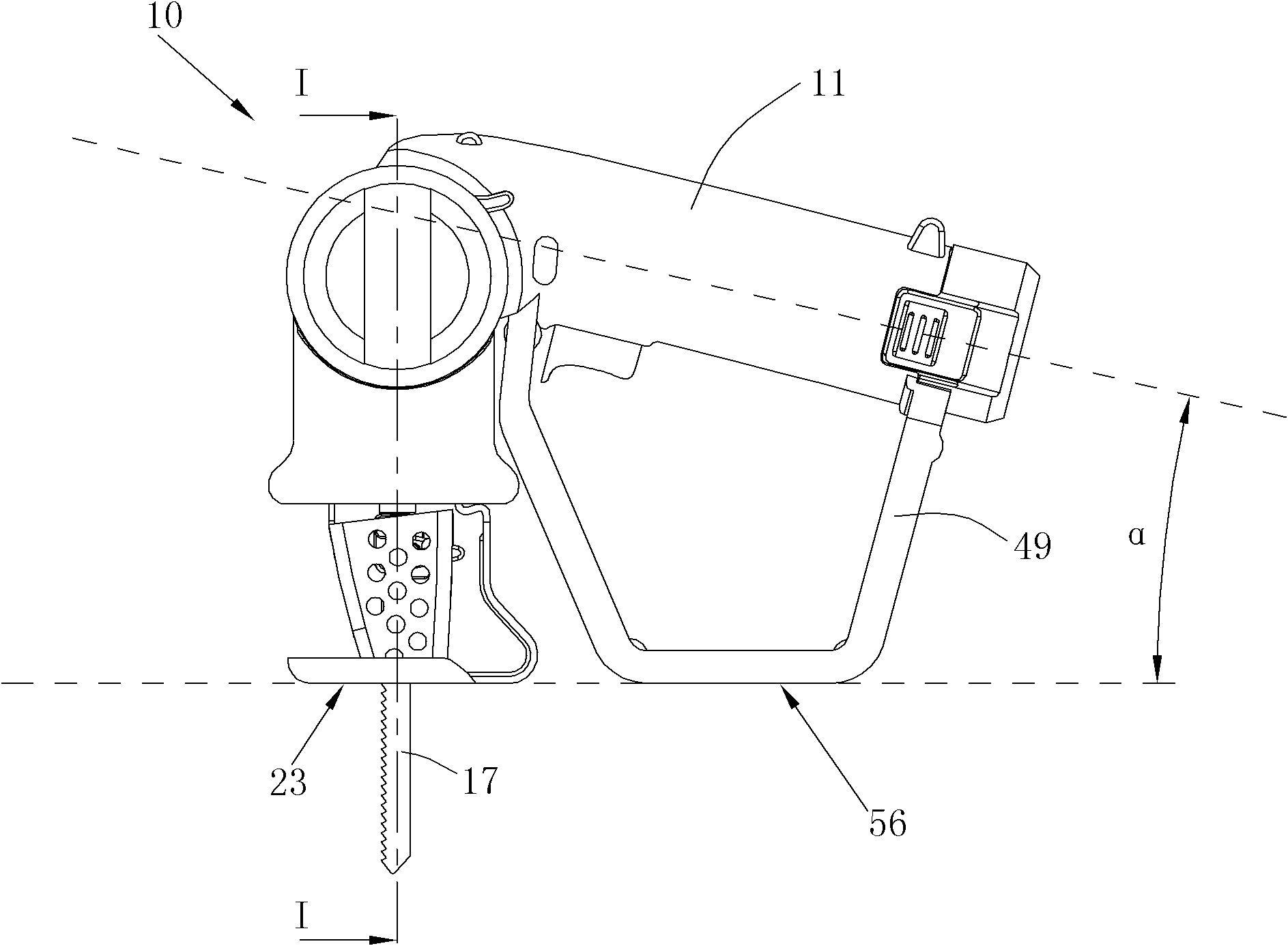

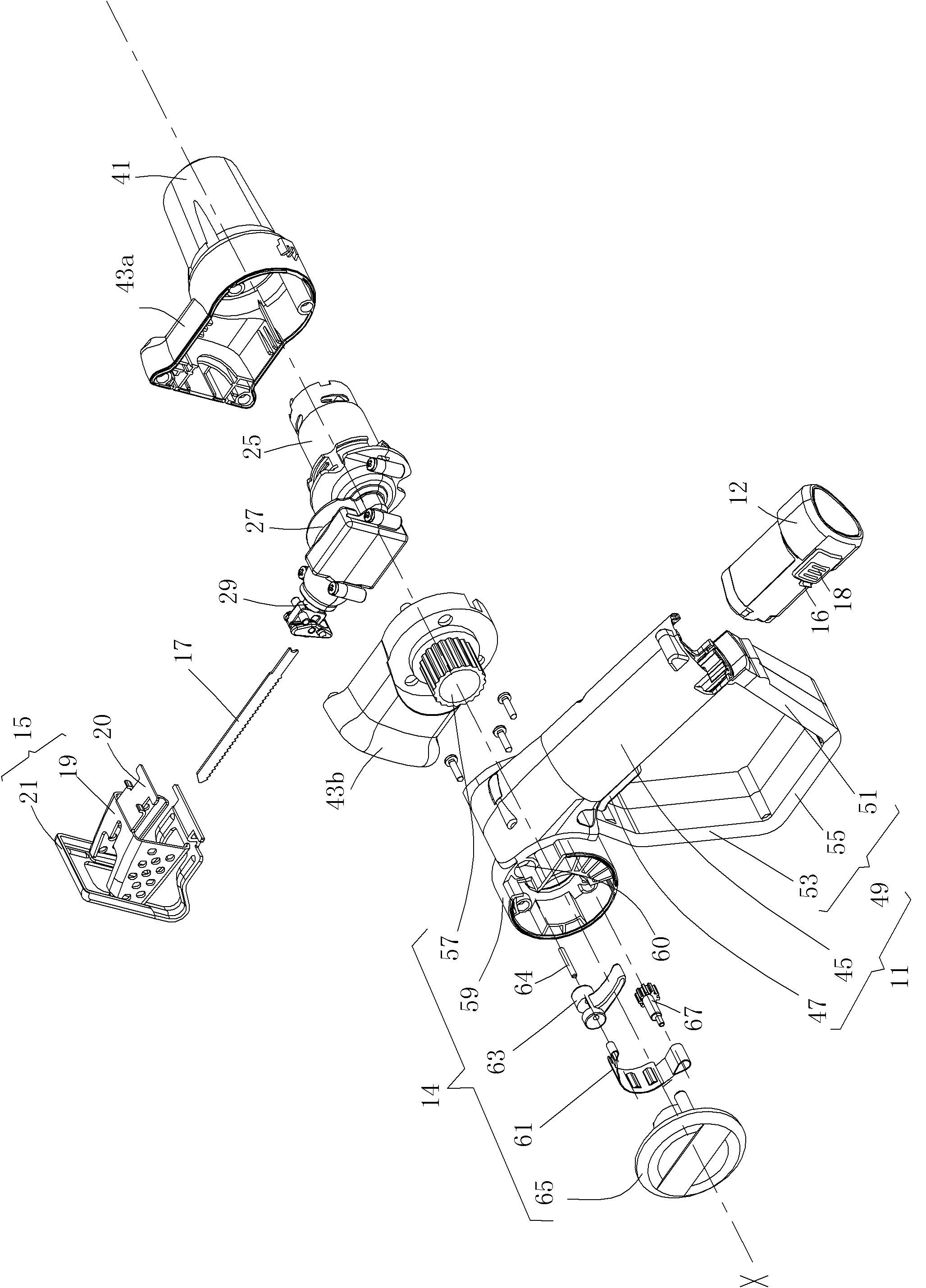

[0061] see figure 1 , the first embodiment of the present invention provides a reciprocating cutting tool 10 . The reciprocating cutting tool 10 includes a handle 11, a battery pack 12 mounted on the handle 11, and a housing 13 pivotally connected to the handle 11, which is arranged on the housing 13 to lock the relative positions of the handle 11 and the housing 13. mechanism 14, and a saw blade 17 protruding from the housing 13.

[0062] Please also refer to figure 1 and image 3 , the casing 13 has a first support frame 15 , and the first support frame 15 includes a main body 19 and a first support plate 21 connected to one end of the main body 19 . The main body 19 is in the shape of a hollow square tube. The first supporting plate 21 has a first abutting surface 23 , and a central hole is provided on the first supporting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com