Countercurrent classifier

A classifier and countercurrent technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of wide particle size distribution of finished products, low classification accuracy, and low extraction rate of fine powder, etc. Achieve the effects of reducing energy consumption, improving classification accuracy and fine powder extraction rate, and improving hardness and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

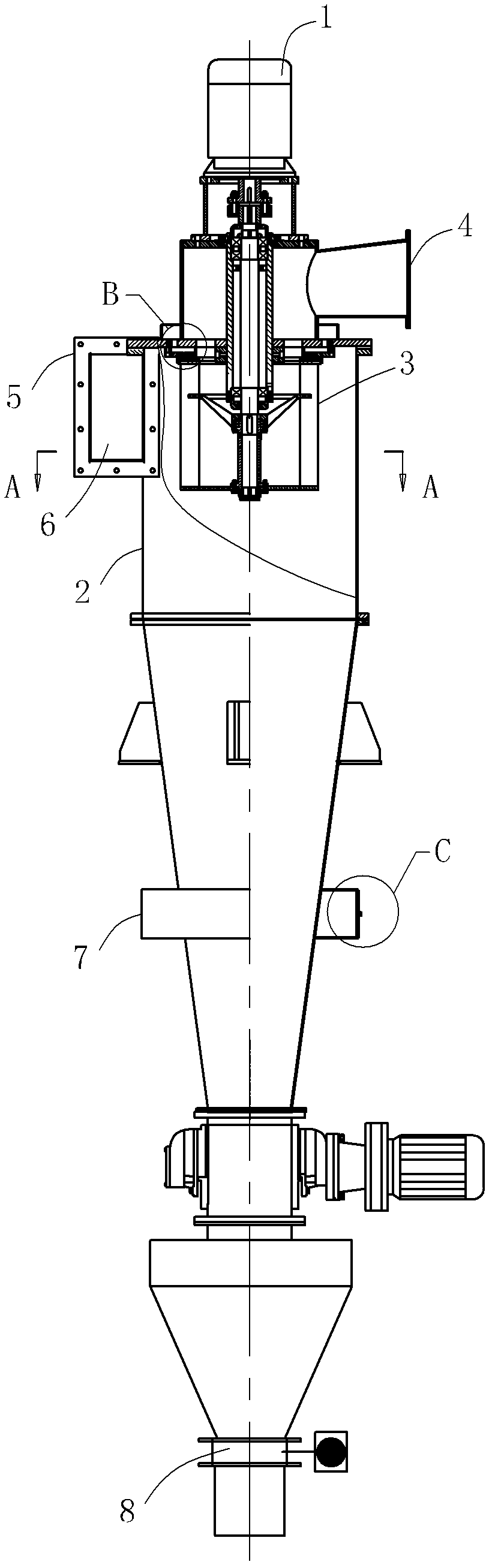

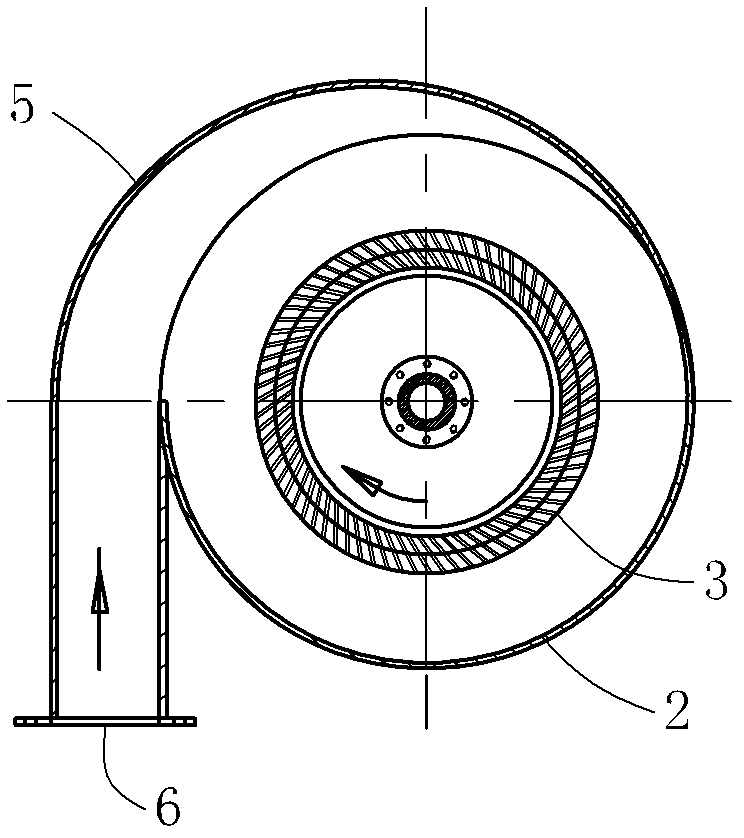

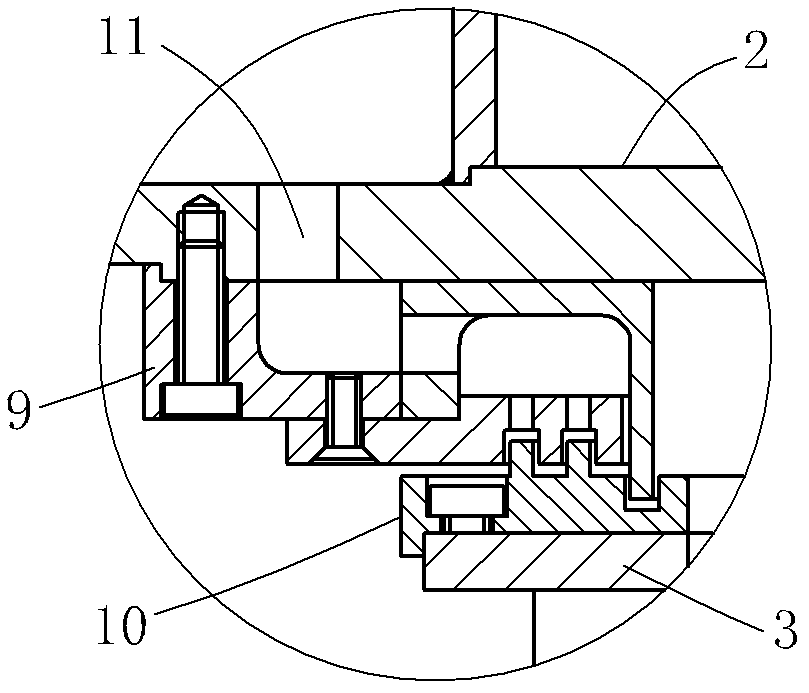

[0020] like figure 1 and figure 2 Commonly shown, a countercurrent classifier includes a body 2, and the body 2 is provided with a classifying wheel 3 driven by a power device, the power device is preferably a frequency conversion motor 1, and the classifying wheel 3 is located on the body 2 Inside, the surface of the blade of the classifying wheel 3 is provided with a carburized layer, which increases the hardness and rigidity of the blade, ensures that the blade does not deform when the classifying wheel 3 rotates at a high speed, and prolongs the service life of the classifying wheel 3. A cyclone feed cover 5 is provided, and a feed port 6 is arranged on the cyclone feed cover 5, and the feed port 6 is arranged along the tangential direction of the body 2 and is located at the position of the classifying wheel 3. The body 2 is provided with an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com