Spray-type evaporative cooling and circulating system of heating device

An evaporative cooling and heating device technology, applied in cooling/ventilation/heating renovation, instruments, electrical digital data processing, etc., can solve the problems of cooling efficiency to be improved, expensive cooling medium, high medium cost, low noise, structure Simple, efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

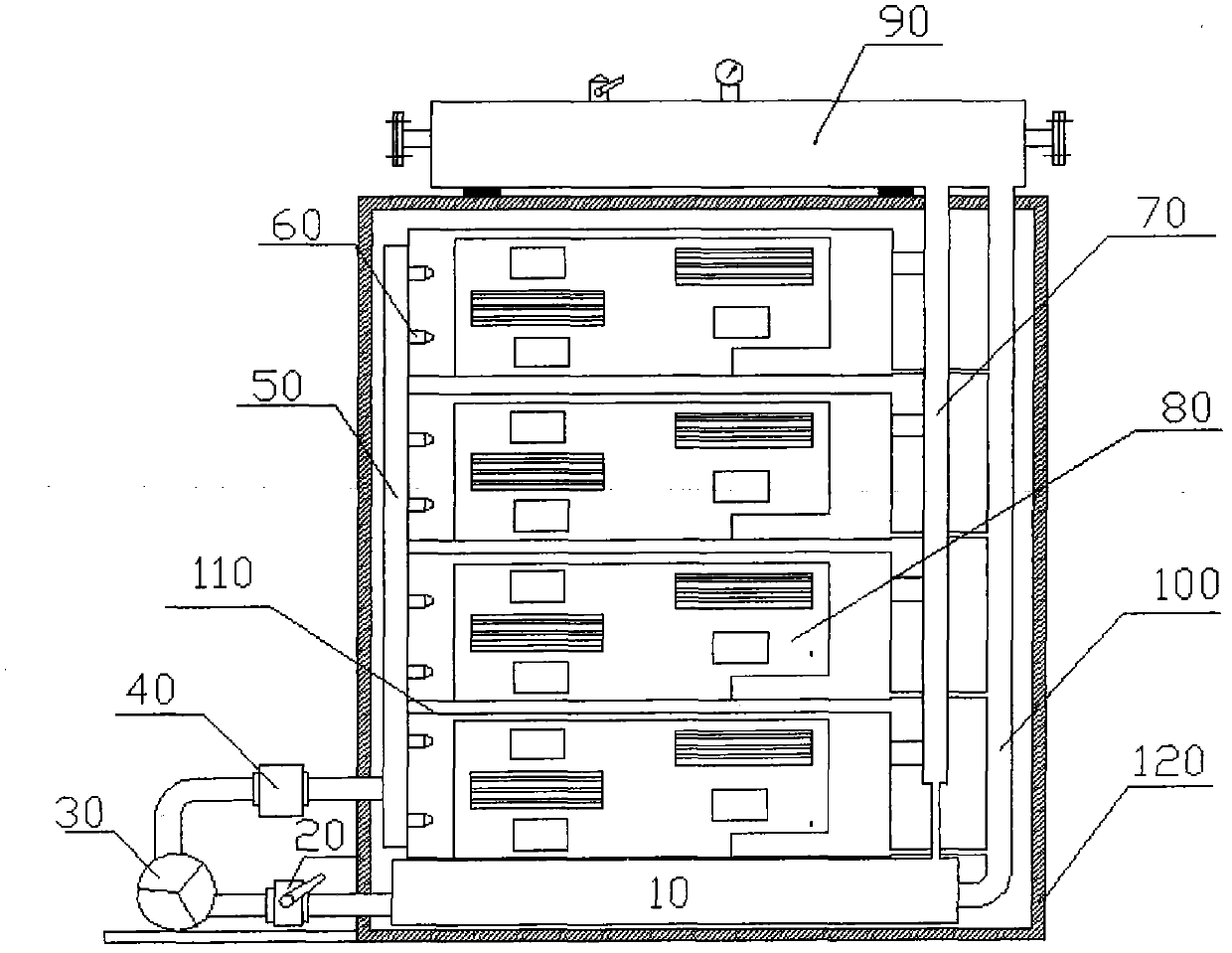

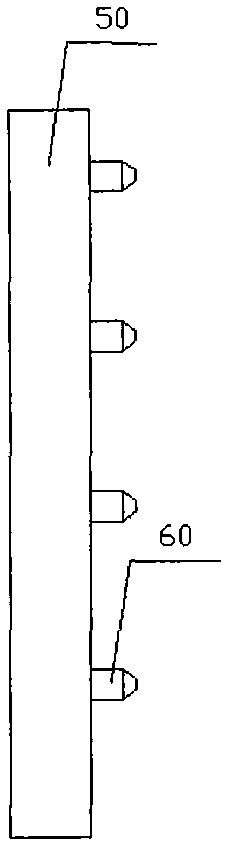

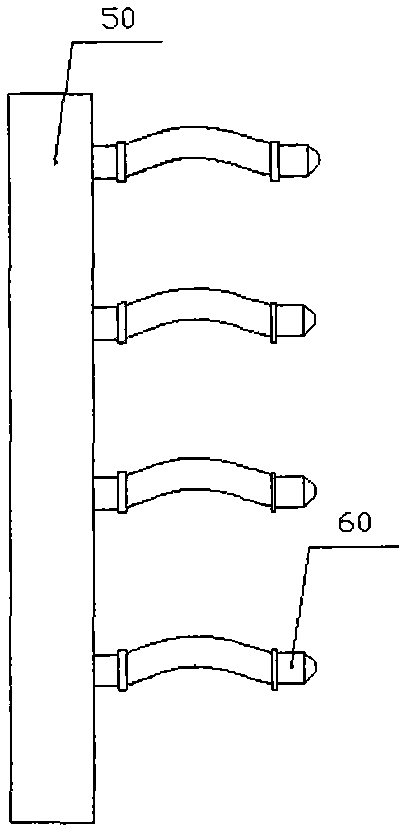

[0025] The concrete implementation method of the present invention is as figure 1 shown. The present invention includes a liquid storage tank 10, a control valve 20, a circulating pump 30, a filter 40, a liquid distributor 50, a nozzle 60, a gas collecting pipe 70, a condenser 90, a liquid return pipe 100, an element sealing box 110 and a heating device cabinet Body 120. The heating device cabinet 120 includes N element sealing boxes 110, N≥1; the element sealing box 110 includes N heating units 80, N≥1; the control valve 20 is arranged between the liquid storage tank 10 and the circulation pump 30 Between, used to adjust the circulating pump flow. The filter 40 is arranged at the front end of the liquid distributor 50 , and the liquid distributor 50 is placed anywhere inside the heating device cabinet 120 ; multiple nozzles 60 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com