Radiating type flexible package battery module group

A soft-packed battery and battery module technology, applied in battery components, secondary batteries, circuits, etc., can solve problems such as short-circuit accidents of battery boxes, non-insulation of conductors, and safety accidents, and achieve easy molding, High electrical conductivity, the effect of extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

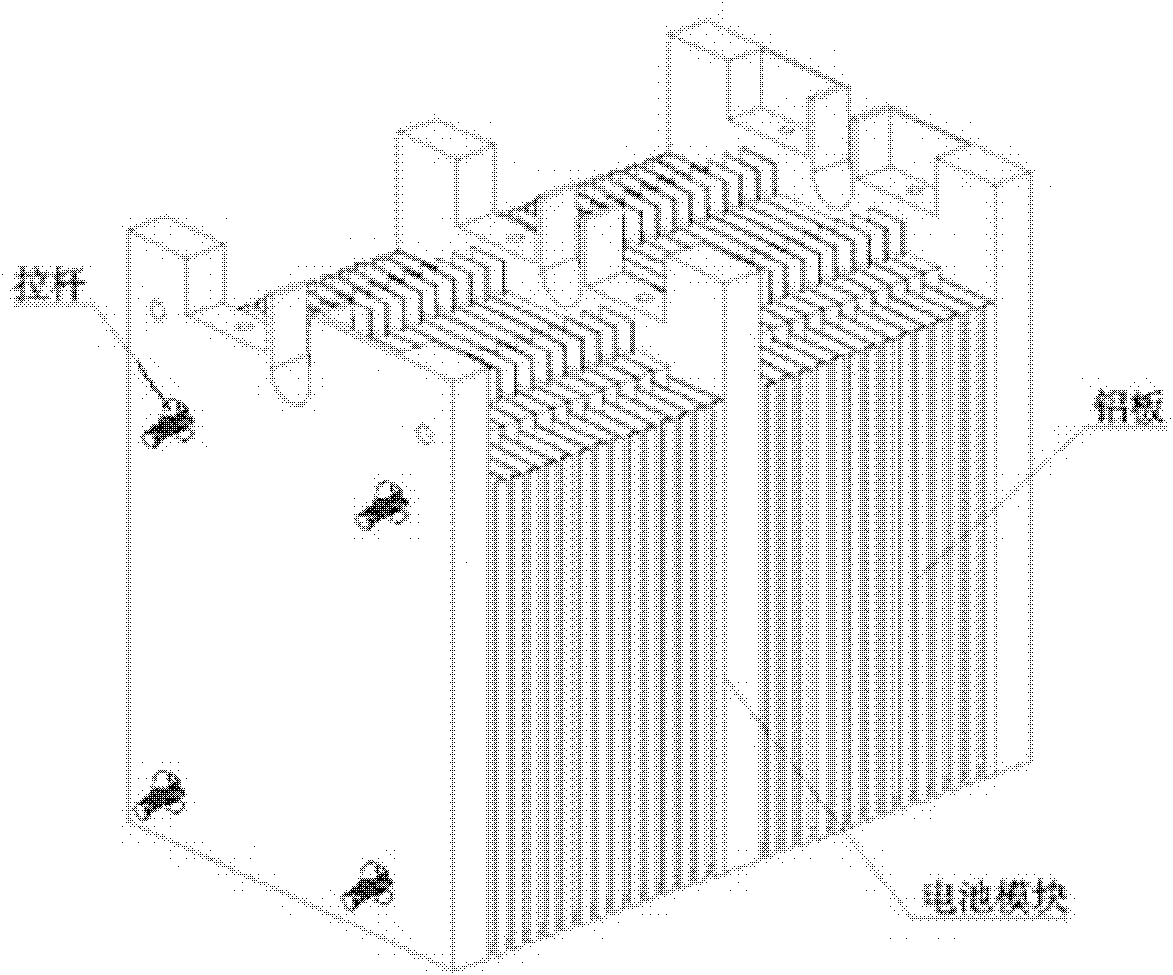

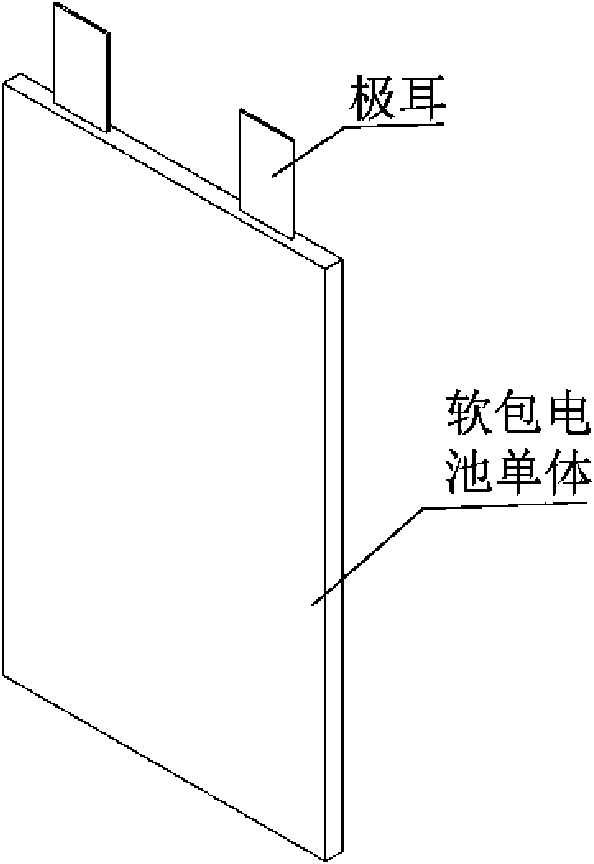

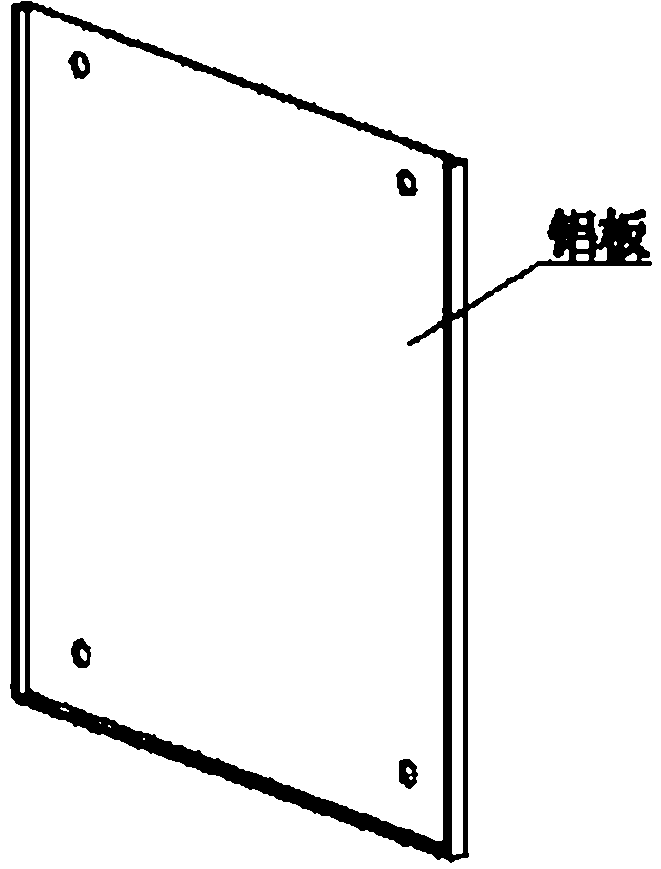

[0066] A kind of flexible packaging battery module group provided by the present invention, the specific structure is as follows figure 1 As shown, the flexible packaged battery module group includes 30 heat dissipation aluminum plates, battery connection plates, 28 flexible packaged single batteries and 3 ABS insulating splints, and each ABS joint splint and heat dissipation aluminum plate is provided with 4 mounting holes. There are 14 soft-packed battery cells and 15 heat-dissipating aluminum plates sandwiched between every two ABS insulating splints. Each soft-packed single battery and heat-dissipating aluminum plate are arranged at intervals. Each heat-dissipating aluminum plate has a folded edge. One side with hem. Connect the 4 mounting holes of the ABS insulating board and the heat-dissipating aluminum board in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com