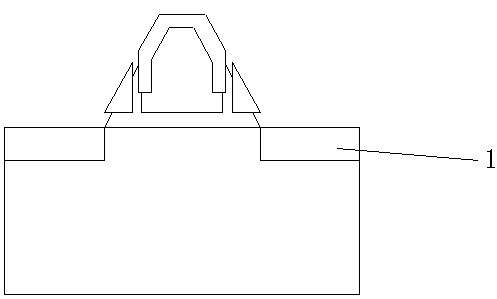

Device structure conducive to eliminating U-shaped nickel silicide and corresponding technology thereof

A technology of nickel silicide and device structure, which can be used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as voids and chamfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

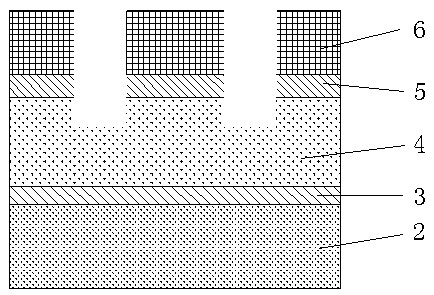

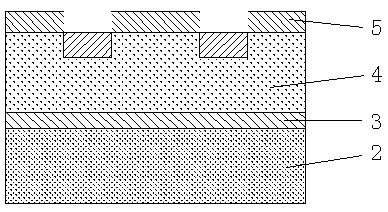

[0030] Please continue to see Figure 2 to Figure 4 shown. In the first step, thin film deposition is performed on polysilicon 4, and then photoresist is spin-coated, and then the silicon oxide layer is opened by dry etching. That is, through flim stack deposition + PR patterning + dry etching (oxide open) to achieve such as figure 2 It is shown with an oxide 5 and a PR layer 6 respectively on polysilicon 4 . In the second step, the photoresist layer 6 on the polysilicon 4 is removed, and then high-temperature oxidation treatment is performed. That is, through PR remove + oxidation to achieve such as image 3 The polysilicon 4 shown, and the photoresist layer 6 is removed. In the third step, the polysilicon gate is etched on the polysilicon 4, and then the oxide 5 is removed. That is, through normal poly etching + oxide strip to achieve such as Figure 4 Polysilicon 4 shown. By first molding the gate with a partially grooved top, a gate nickel silicide with a straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com