Television checking camera combination structure for inside of pipe fitting

A combined structure and camera technology, applied in nuclear power generation, nuclear reactor monitoring, reactors, etc., can solve the problem of high radioactive dose and achieve good lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

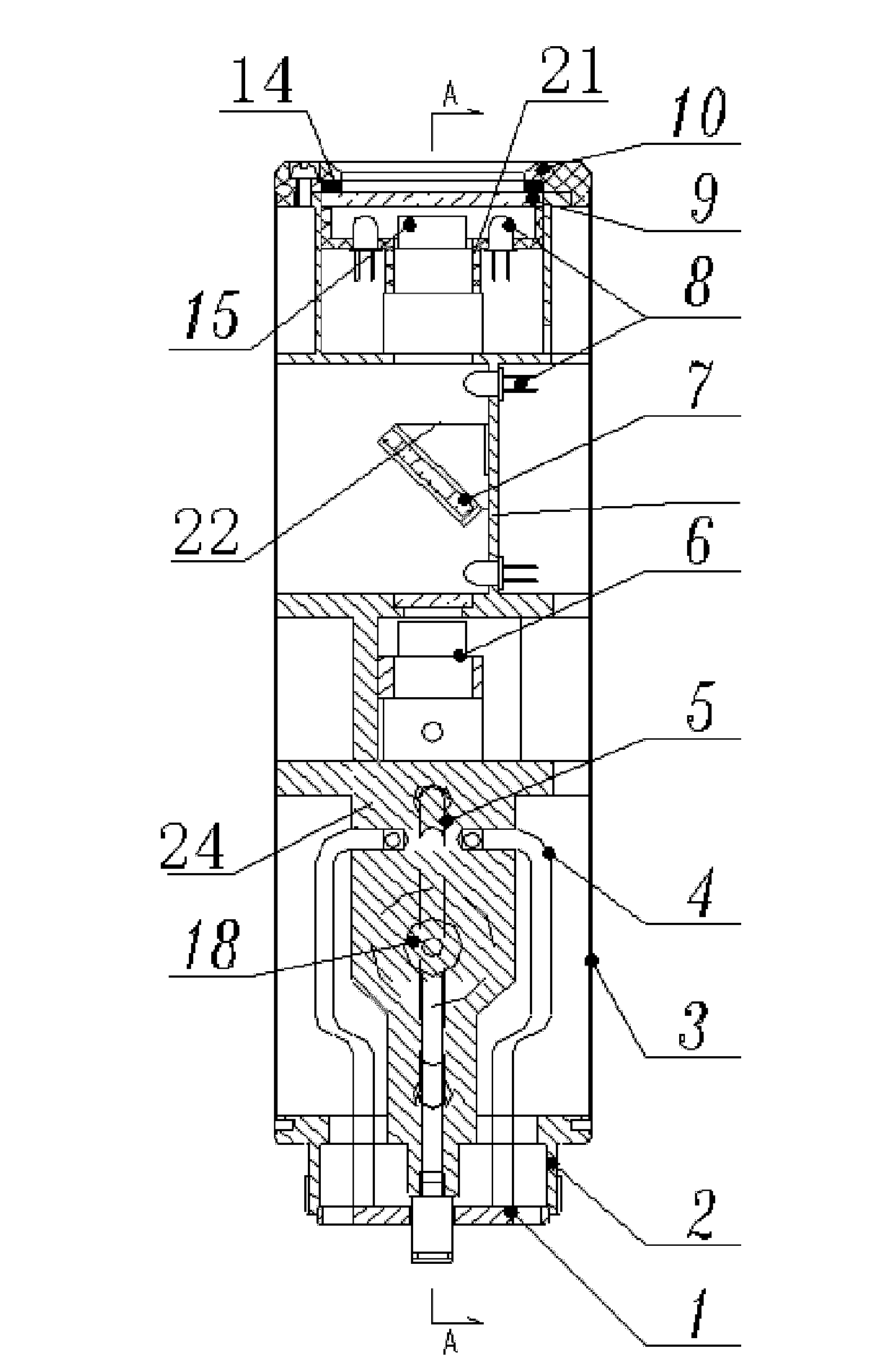

[0016] The combined structure of the TV inspection camera inside the pipe fittings includes a cylindrical cover 3. The top of the cylindrical cover 3 is fixedly connected with a top cover 10 through threads. A circular frame structure with multiple cavities, the bottom of the combined structure body 2 is fixedly connected with a positioning plate 1, and four cavities are opened on the combined structure body 2, a bracket 21 is installed in the cavity on the top, and a bracket 21 is installed on the bracket 21. There is a camera 15, the periphery of the camera 15 is evenly equipped with light emitting diodes 8, the top of the bracket 21 is equipped with a glass baffle 9, an O-ring 14 is arranged between the glass baffle 9 and the top cover 10, and the combined structure body 2 The cavity in the middle and upper part is equipped with a support plate 23, a mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com