Numerical method for graded crushed stone dynamic triaxial test

A dynamic triaxial test and graded crushed stone technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of unfavorable revealing of the deformation behavior of graded crushed stone, high test cost and low efficiency, etc. To achieve the effect of saving research costs and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

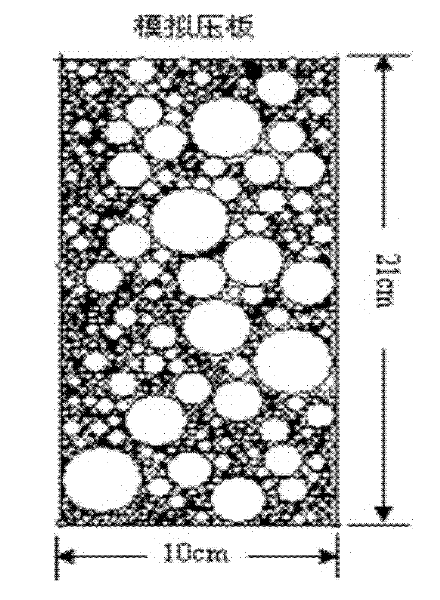

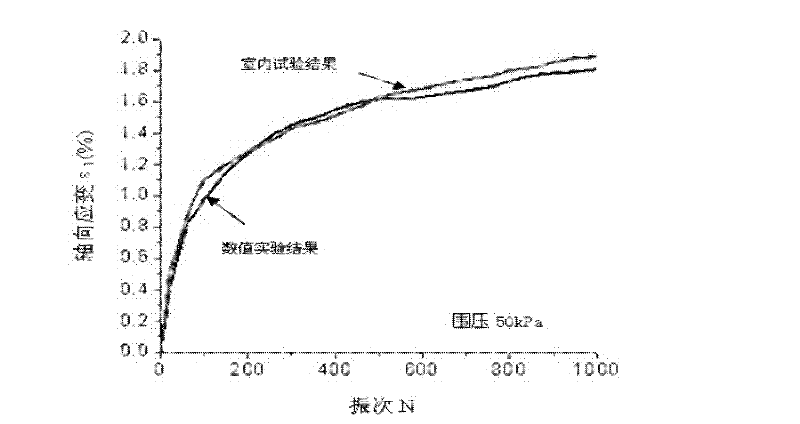

[0071] According to the technical scheme of the present invention, this example provides a numerical simulation method for the dynamic triaxial test of graded crushed stone, taking Ankang Yinghu limestone crushed stone as an example, the crushed stone density test results are shown in Table 1, and the micromechanical parameters are shown in Table 1 2.

[0072] Table 1 crushed stone density

[0073] Aggregate particle size (mm)

20~40

10~20

5~10

2~5

Apparent density (g / cm3)

2.712

2.709

2.692

2.681

[0074] Table 2 Micromechanical parameters

[0075] Poisson's ratio

Shear modulus (GPa)

0.2

220

0.5

[0076] Table 3 aggregate gradation

[0077]

[0078] Taking the gradation A in Table 3 as an example to illustrate the implementation steps of the numerical simulation method of the triaxial test of the graded crushed stone are:

[0079] 1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com