Temperature online measuring method for plate blank in production process of heating furnace

A technology of production process, measurement method, applied in the direction of thermometer, measuring device, measuring heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

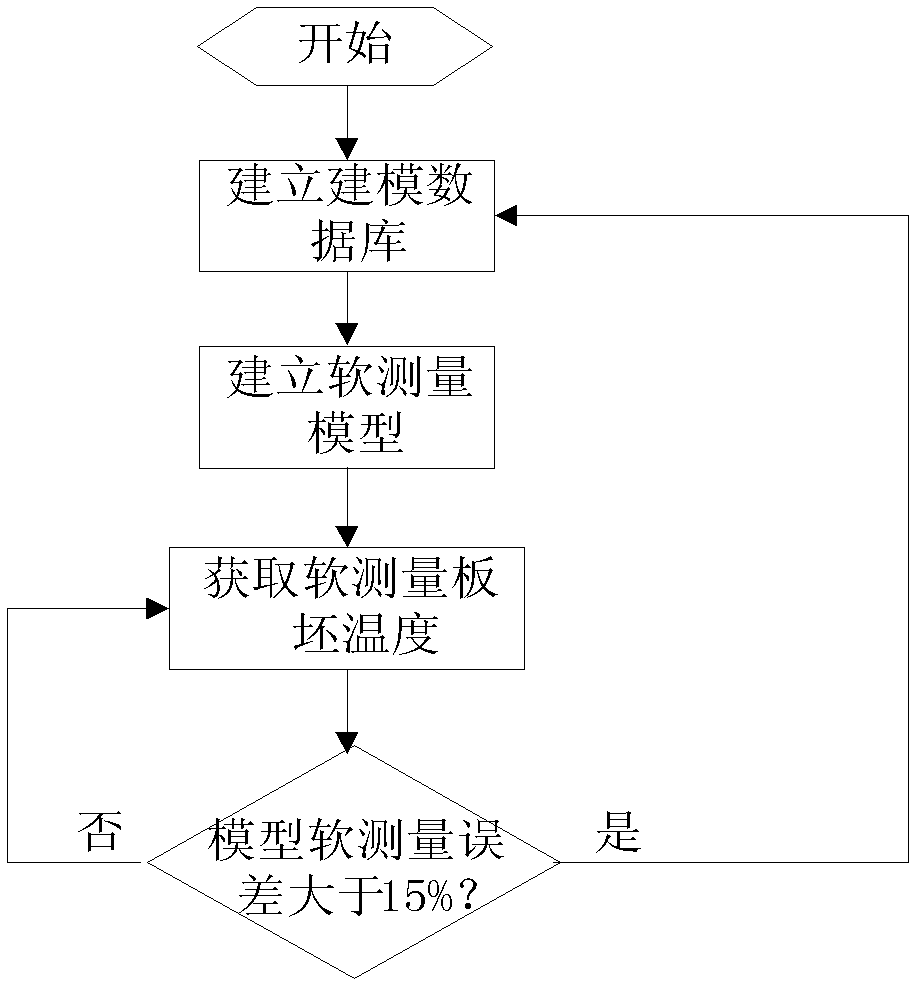

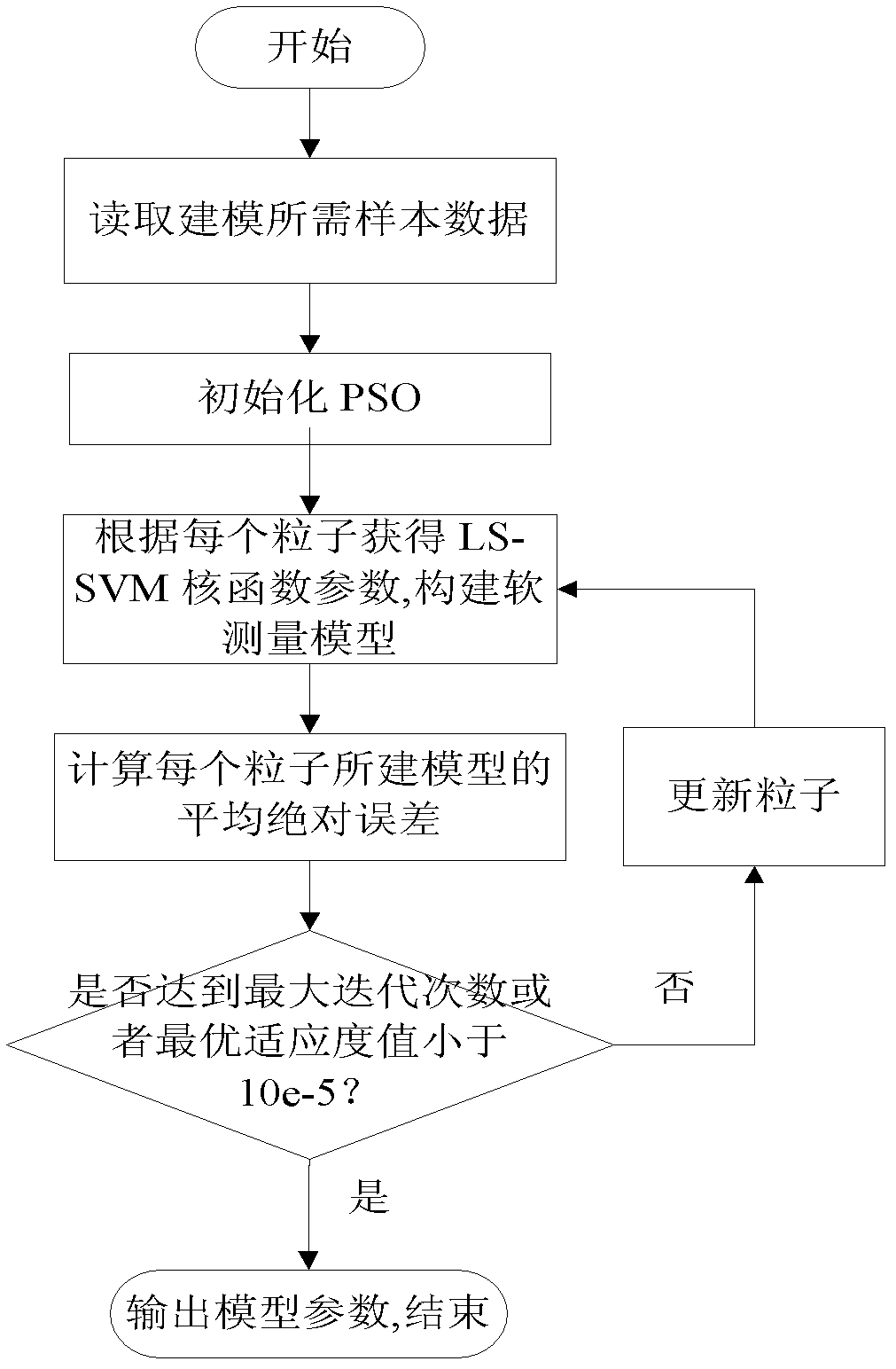

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0048] This embodiment is based on the background of the production process of heating furnaces in iron and steel enterprises. The hardware platform used is: one PC, WindowsXP and above operating system as a supporting platform, and Microsoft SQL Server 2000 database system is installed to support data management.

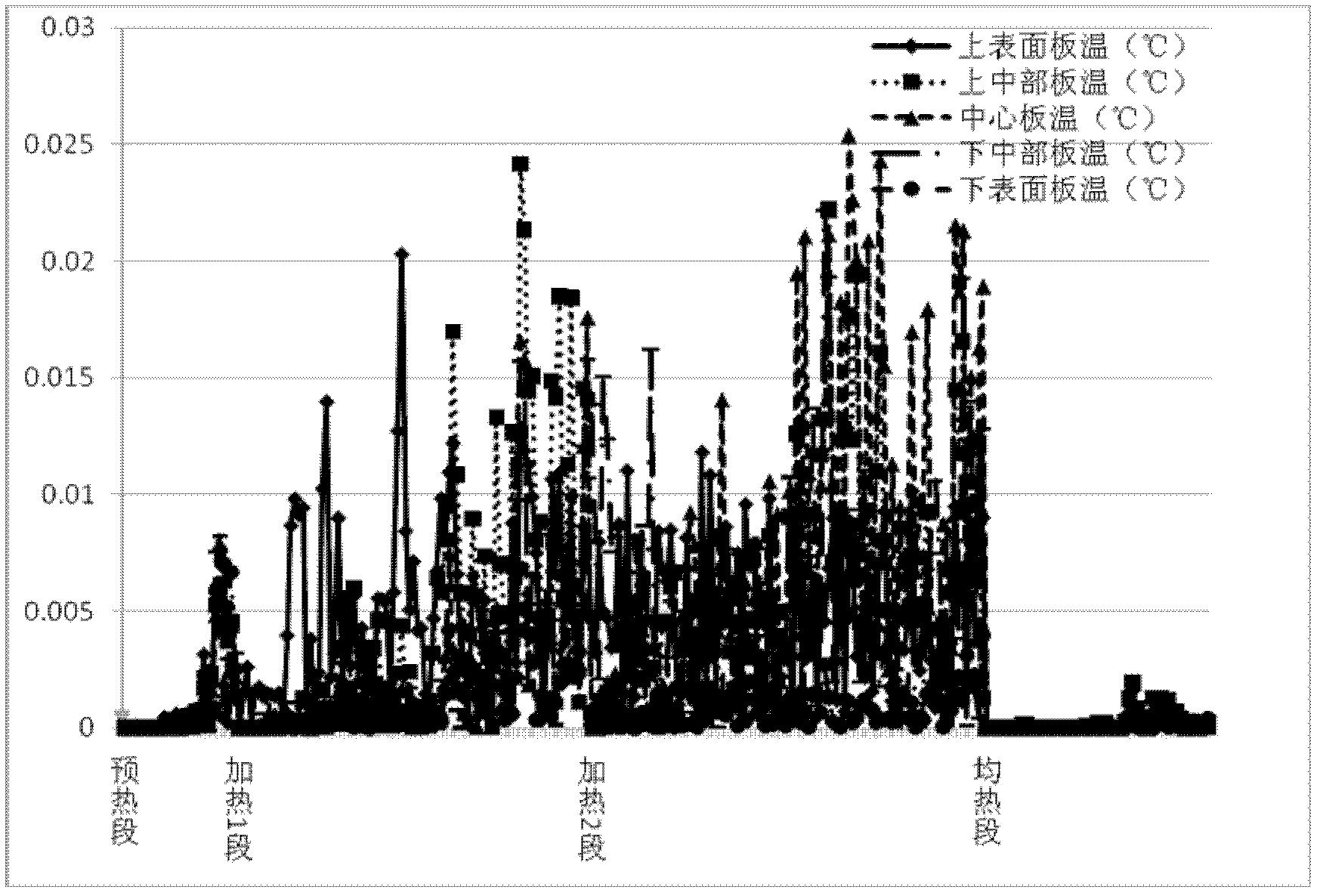

[0049] This embodiment adopts the performance of the method proposed in the present invention to test the real data obtained at the production site, and the data situation is shown in Table 1 for details:

[0050] Table 1 Details of experimental data

[0051]

[0052] n in this example 1 = 3, n 1 = 2, 7 input features include the slab temperature 3 units before the measurement time, the slab temperature 2 units before the measurement time, the slab temperature 1 unit time before the measurement time, and the 2 units before the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com