Photonic crystal fiber grating temperature sensor based on liquid filling and manufacturing method thereof

A photonic crystal fiber and temperature sensor technology, which is applied in the field of fiber grating sensors, can solve the problems of low sensitivity of fiber grating temperature sensors and the small range of Bragg wavelength movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

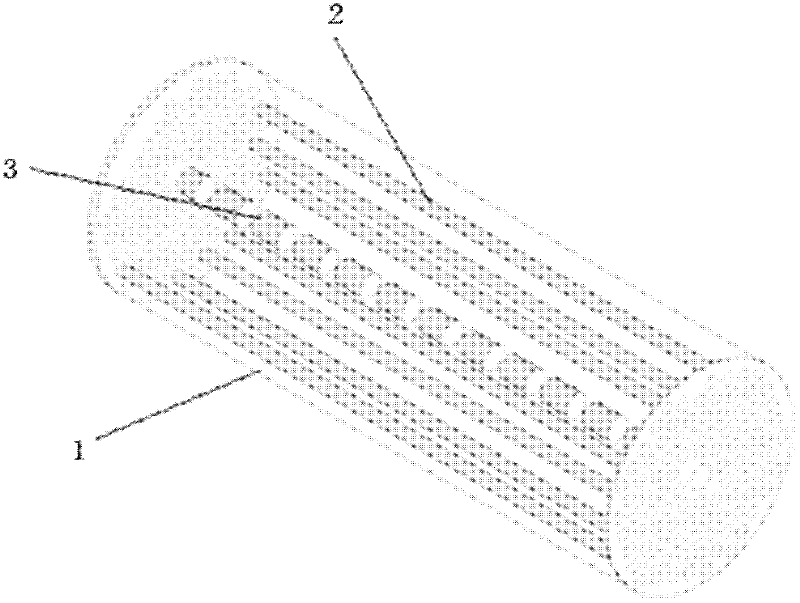

[0038] A temperature sensor based on a liquid-filled photonic crystal fiber grating, including a photonic crystal fiber cladding 1, a germanium-doped fiber core 3 is arranged at the central axis of the fiber cladding 1, and a Bragg grating structure is engraved on the surface of the fiber core 3, Air holes 2 are penetrated axially along the fiber cladding 1, and these air holes 2 are uniformly distributed around the fiber core 3 and form a multi-layer matrix structure, and the air holes 2 are filled with a refractive index matching liquid with thermo-optic sensitive effect.

[0039] A PCF optical fiber cladding 1 with an outer diameter of 125 μm is used. The air holes in the cladding are arranged in a seven-layer matrix. The diameter of the air hole 2 is 1 μm, and the distance between the air holes is 1.55 μm. The fiber core 3 is made of germanium-doped photosensitive silica material, with a diameter of 2.1 μm, the refractive index of the germanium-doped silicon core is 1.45, a...

Embodiment example 2

[0047] Using the PCF and grating with the same structure as in Example 1, inject a thermo-photosensitive refractive index matching liquid, whose refractive index is 1.43 (at 25°C), and obtain a temperature sensitivity coefficient of 100pm / °C. In this case, the applied product is 25°C , 45°C, 65°C reflection spectra such as Figure 4 , When connected with an optical fiber sensor analyzer with a demodulation accuracy of 1pm, the sensor can achieve a temperature measurement sensitivity of 0.01°C.

Embodiment example 3

[0049] Optimally designed photonic crystal fiber structure, PCF fiber cladding 1 with an outer diameter of 125 μm, cladding air holes arranged in a 5-layer matrix, air hole 2 diameter 1.2 μm, air hole distance 1.6 μm, germanium-doped silica fiber core The refractive index is 1.46, and the air hole is filled with a thermo-optic sensitive refractive index matching liquid. Its refractive index is 1.43 (at 25°C), and the fiber grating can obtain a temperature sensitivity coefficient of 263pm / °C. In this case, the applied product is -15°C to 65°C ℃, the fiber grating wavelength shift changes as Figure 5 , when the sensor is connected with an optical fiber sensor analyzer with a demodulation accuracy of 1pm, the sensor can achieve a temperature measurement sensitivity of 0.004°C. When the demodulation device is used to demodulate the device with a resolution of 0.25pm, this product can increase the temperature measurement range from -15°C to 65°C, and the sensitivity can be increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com