Solar furnace adopting self-spinning and elevation tracking mode

A technology for tracking and tracking the sun at an elevation angle, applied in the field of solar furnaces, can solve problems such as the inability to ensure that the center point of the heliostat is always located in the meridian plane, limited application range, high cost of materials and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

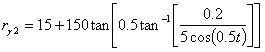

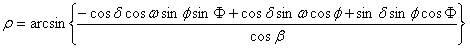

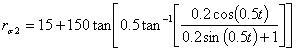

[0036] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: principle structural diagram of the present invention is by Figure 1.1 , Figure 1.2 , Figure 1.3 , Figure 1.4 , Figure 1.5 and figure 2 Given, wherein the heliostat 2 faces south, and its spin axis 6 points to the concentrating mirror 3 along the horizontal direction; The light reflector 3 is a spherical mirror with a diameter of 350mm and a radius of curvature of 700mm. The condenser reflector 3 is placed at a position where the target distance 4 is 5m; the spherical mirror focuses the incident sunlight for the second time and forms a High temperature zone 5. The reflective surface of the heliostat 2 is composed of a sub-mirror array of 25 sub-mirrors 7 in 5 rows and 5 columns. The sub-mirrors are plane mirrors with a size of 500mm x 500mm. The heliostat 2 tracks the sun in the way of spin elevation tracking, and the principle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com