Sludge incineration method and sludge incineration facility

A technology of sludge incineration and sludge, applied in combustion methods, lighting and heating equipment, incinerators, etc., can solve problems such as difficult to reach preheating temperature, difficult to adjust preheating temperature, difficult to meet temperature requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] (Embodiment 1)

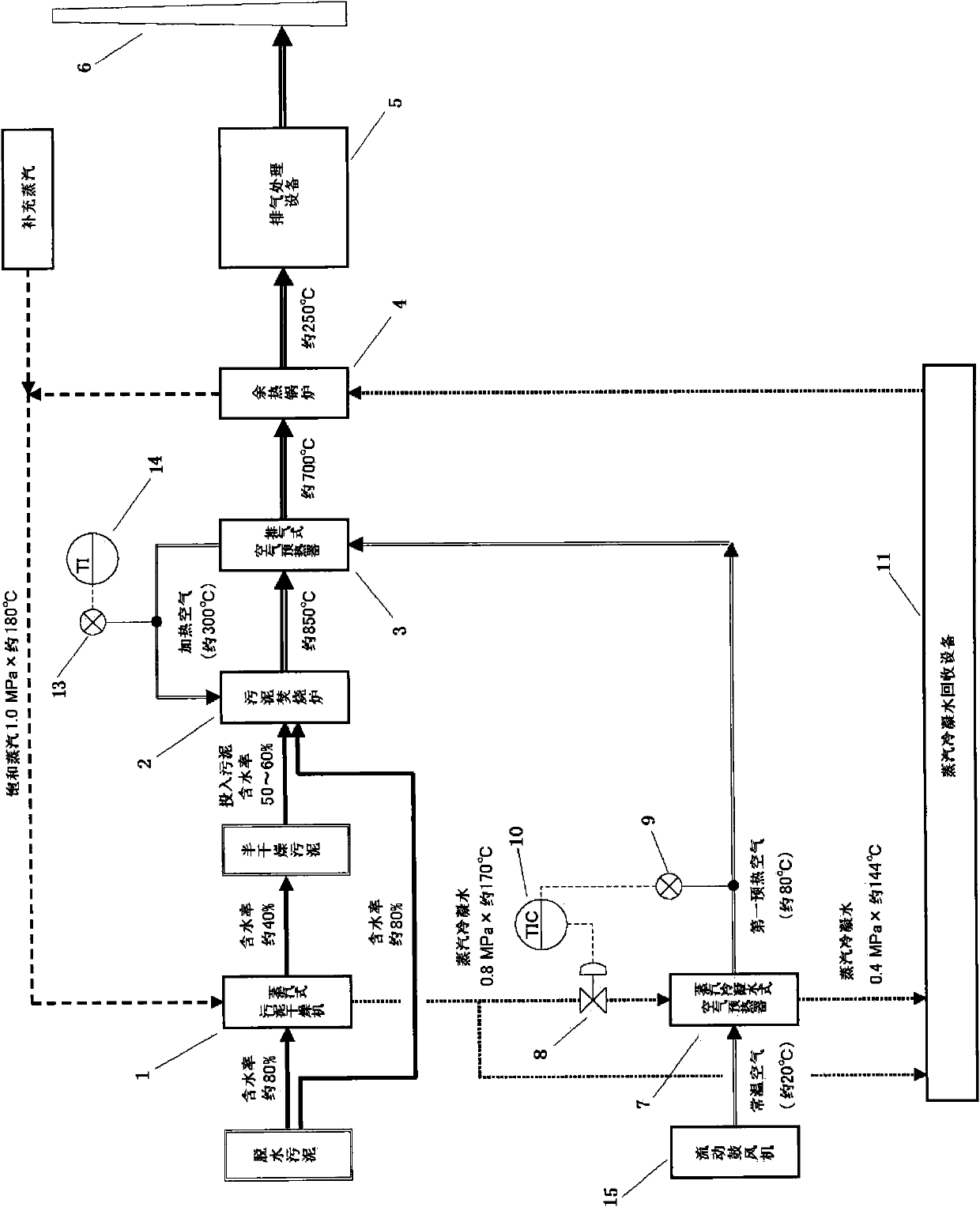

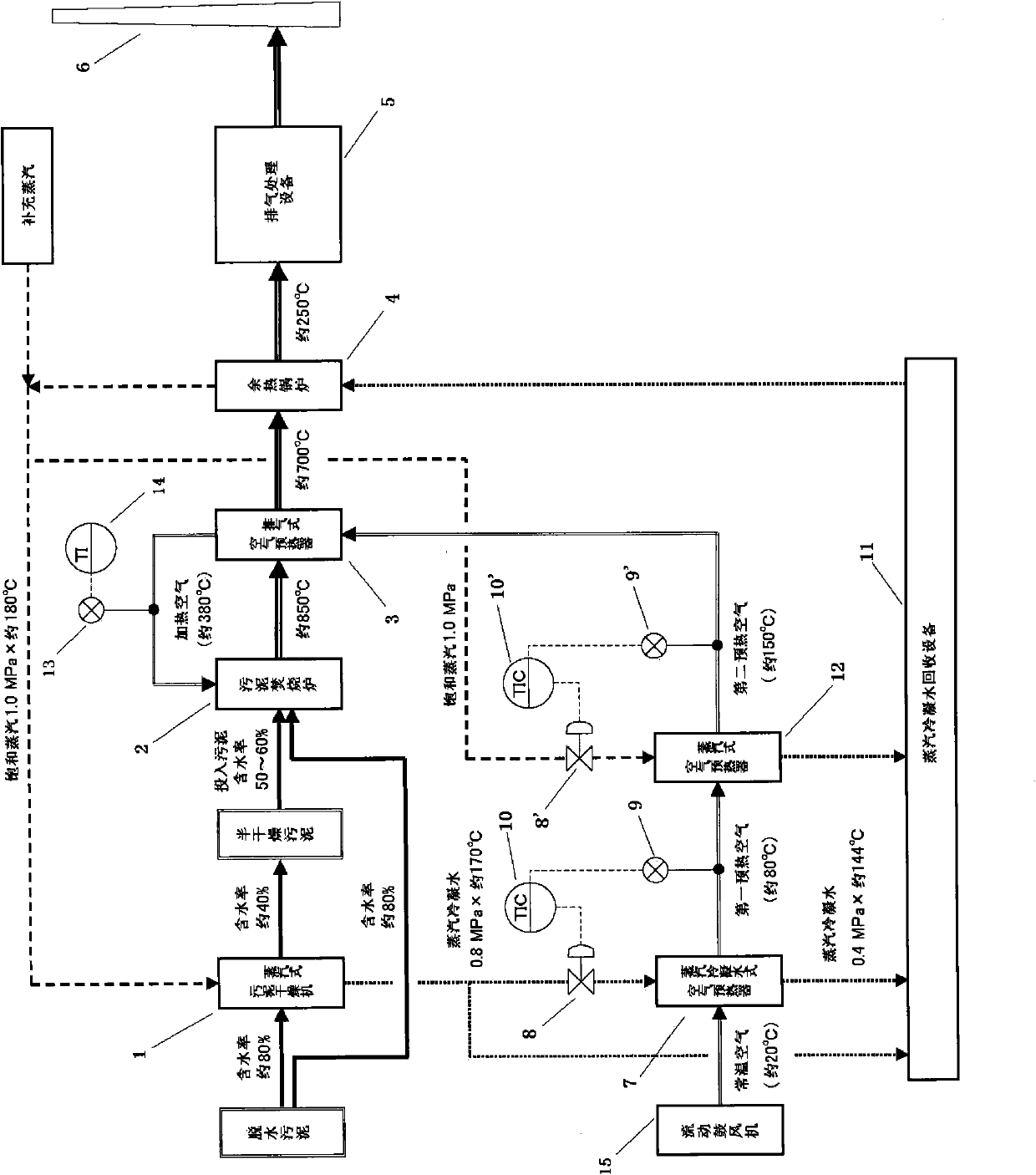

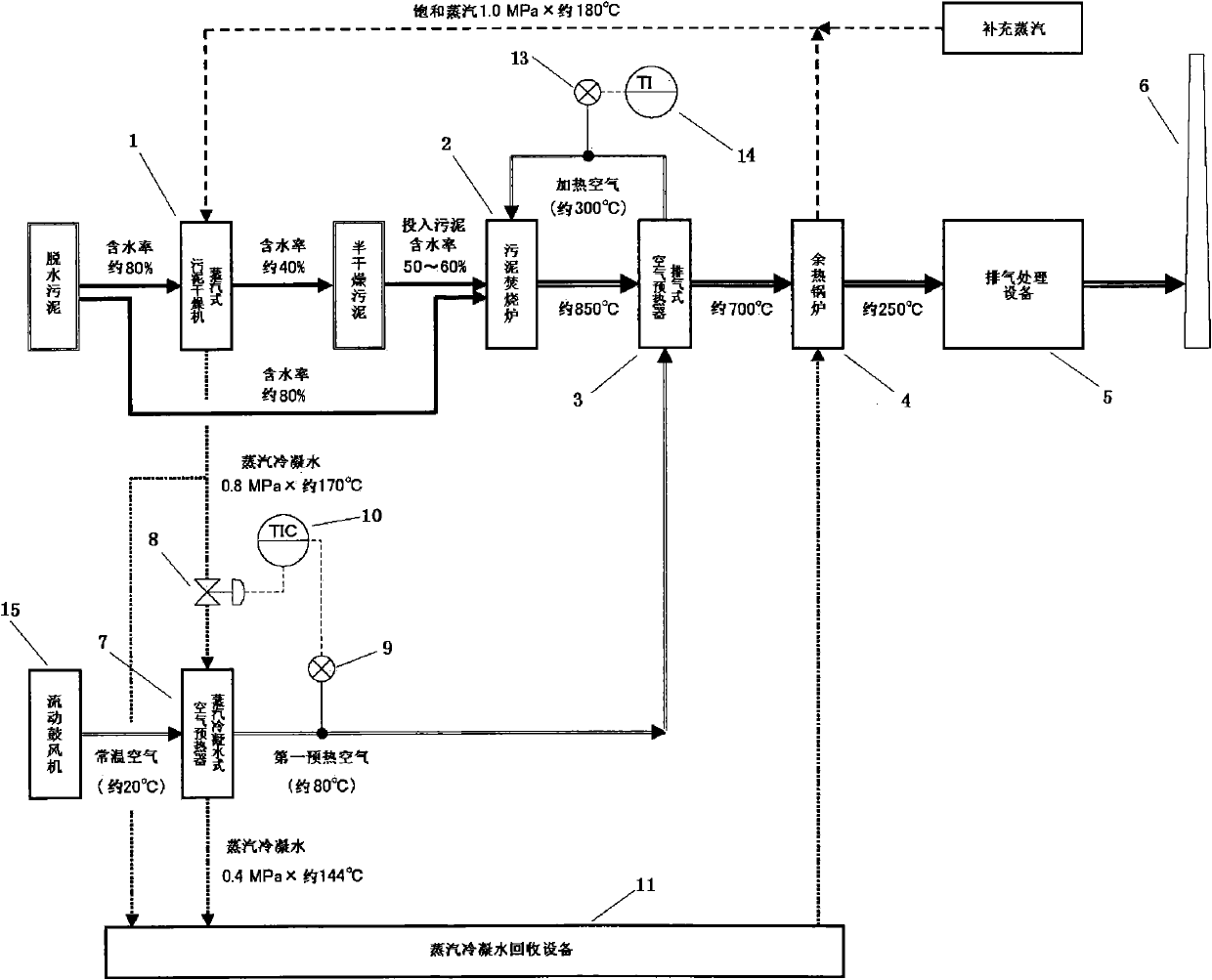

[0016] Below, refer to the attached figure 1 , Embodiment 1 of the present invention will be described.

[0017] Such as figure 1 As shown, the sludge drying and incineration system of Embodiment 1 of the present invention has: a steam sludge dryer 1, which dries the dewatered sludge by steam; a sludge incinerator 2, which is used for drying semi-dried sludge The sludge is incinerated; the exhaust type air preheater 3, which is arranged behind the sludge incinerator 2, utilizes the high-temperature exhaust gas discharged from the sludge incinerator 2 to heat the air, and uses the heated air as combustion air to The sludge incinerator 2 is supplied; the waste heat boiler 4 recovers the heat of the exhaust gas discharged from the exhaust air preheater 3 and generates steam, which is fed back to the steam sludge dryer 1; exhaust gas treatment equipment 5. It cools and purifies the exhaust gas recovered from waste heat; the chimney 6 is used to discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com