Overrunning gear-shifting device

A second-speed, set-up technology, applied in transmissions, non-mechanical drive clutches, one-way clutches, etc., can solve problems such as difficult repairs, slow response to speed changes, limited load torque, etc., and achieves a simple and novel structure, simple structure, and easy The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

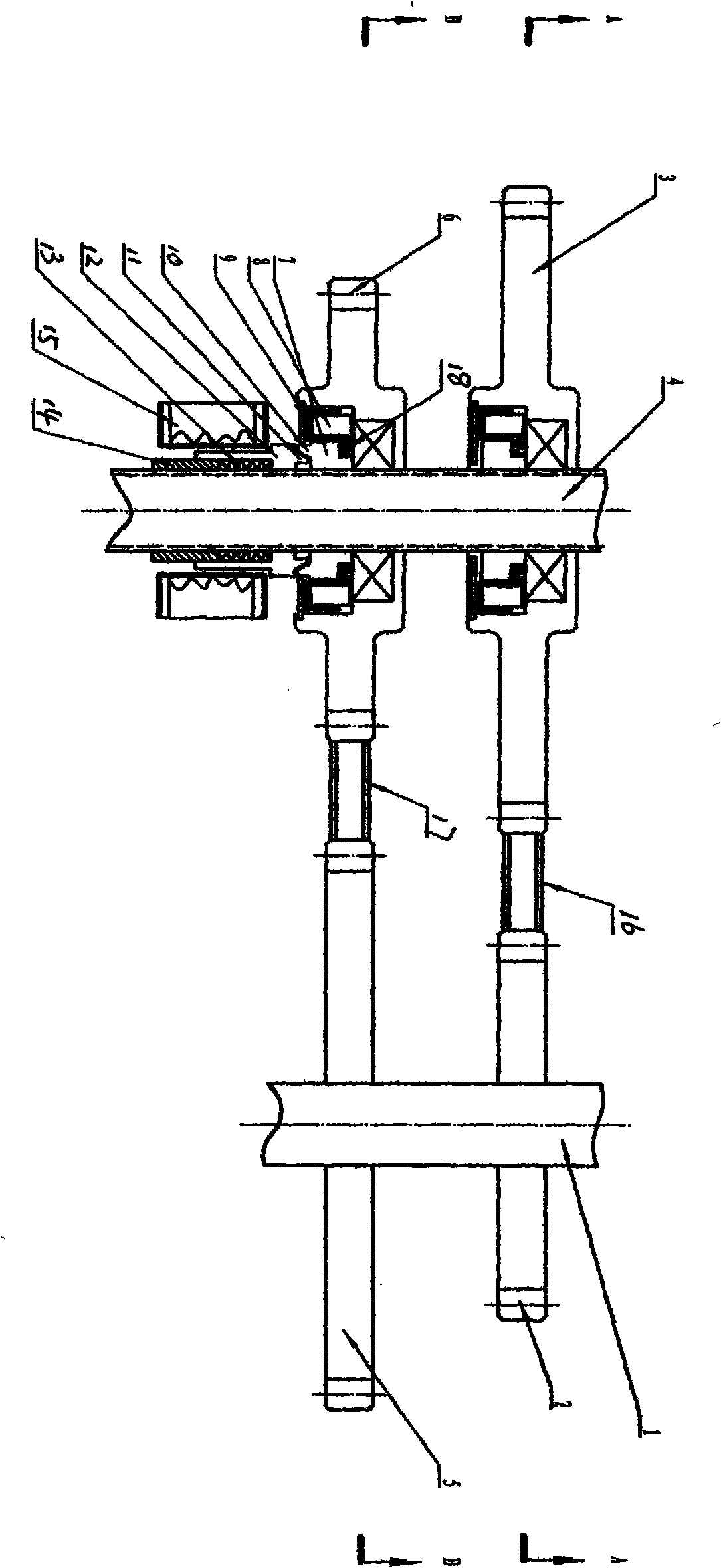

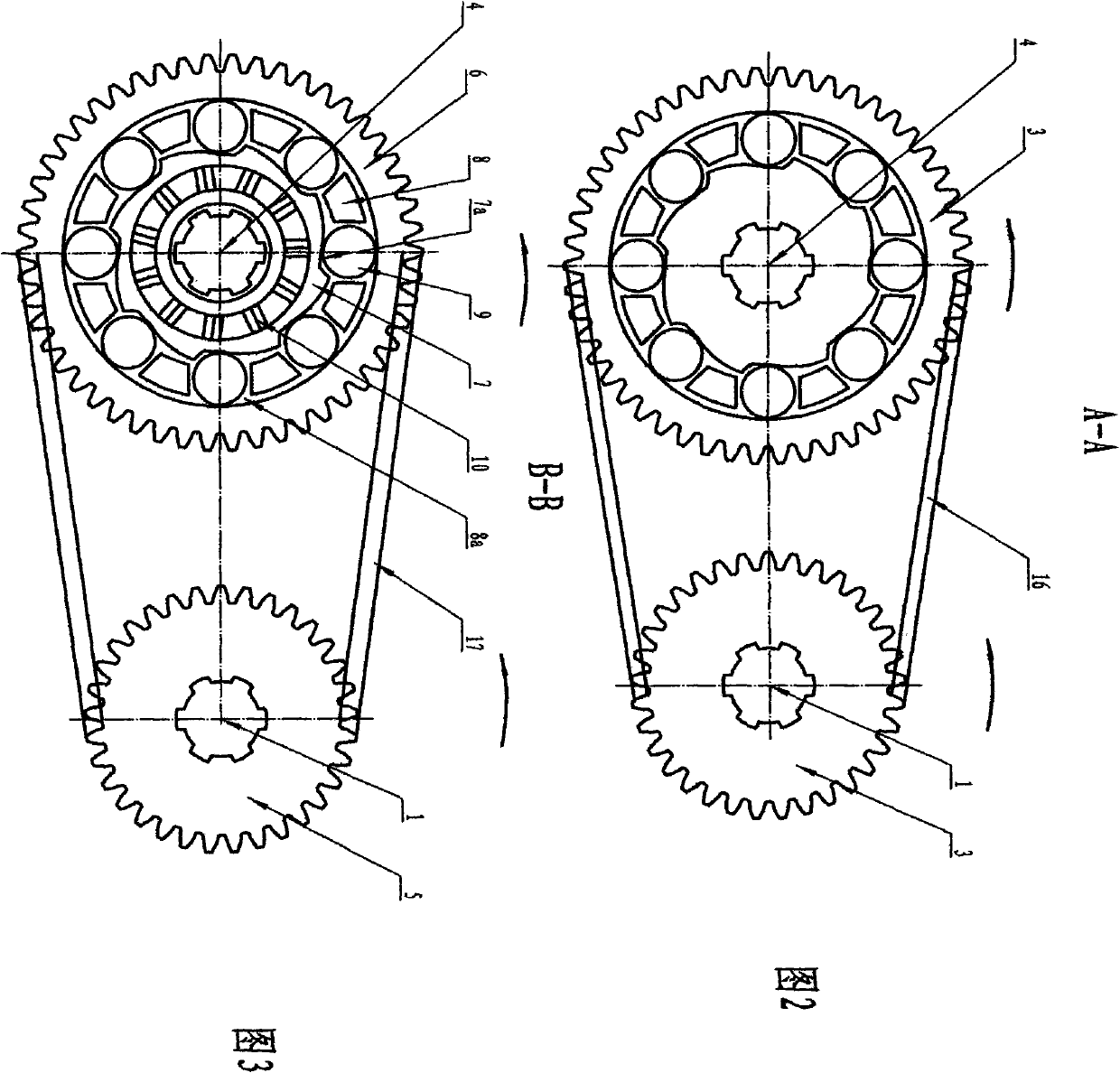

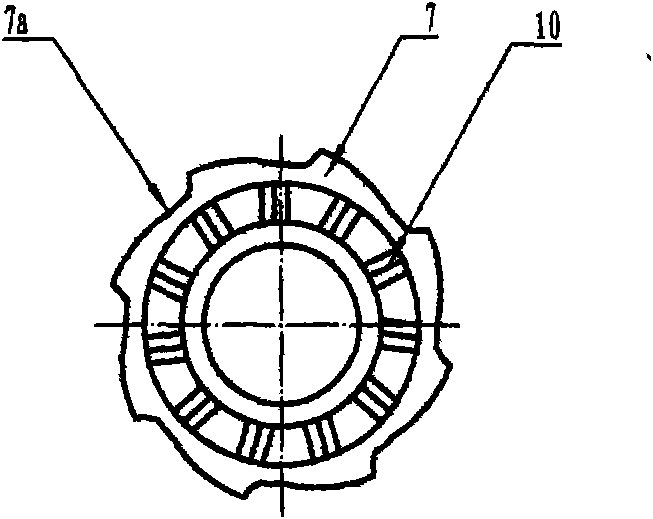

[0012] see image 3 : the second gear driven unidirectional device includes a second gear driven sprocket 6 meshed with the second gear driving sprocket 5, and the left part of the second gear driven sprocket 6 is installed on the driven shaft through a bearing 4, the center of the right part of the second gear driven sprocket 6 is equipped with a second gear driven cam 7, and the second gear driven cam 7 is looped on the driven shaft 4, and the second gear driven cam A second gear driven floating sleeve 8 is installed between 7 and the inner wall of the second gear driven sprocket 6, and a group of second gear driven cam curved surfaces 7a are arranged on the outer circumference of the second gear driven cam 7. The second gear The driven cam curved surfaces 7a are all smooth curved surfaces with lift characteristics, and each second gear driven cam curved surface 7a is distributed on the outer circumference of the second gear driven cam 7 in the same direction of rotation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com