Sealing device and rolling bearing device provided with sealing device

A technology for sealing devices and rolling bearings, which is applied in the direction of rolling contact bearings, roller bearings, and rotating bearings. It can solve problems such as difficult adjustments, manufacturing errors of sealing lips, inability to obtain heat prevention effects and sealing effects, and eliminate defects. Conditions, the effect of maintaining the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

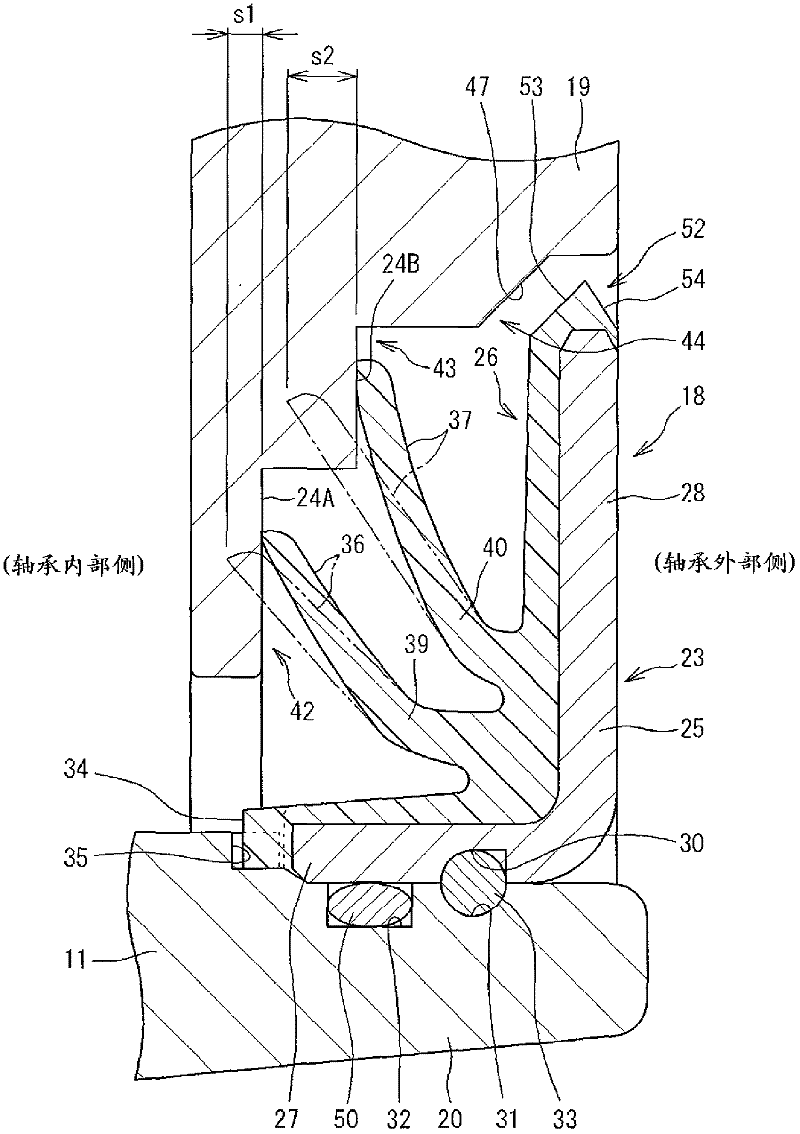

[0018] Hereinafter, a sealing device and a rolling bearing device according to the present invention will be described with reference to the drawings. figure 1 It is a sectional view showing the sealing device and the rolling bearing according to the first embodiment of the present invention. figure 2 is showing figure 1 An enlarged cross-sectional view of the sealing device in . In addition, the left-right direction in these figures is called an axial direction, and the up-down direction is called a radial direction. Also, regarding the axial direction, a direction from the inside of the rolling bearing 10 toward the outside is called an axially outer side, and a direction from the outside of the rolling bearing 10 toward the inside is called an axially inner side.

[0019] Such as figure 1 As shown, the rolling bearing 10 is, for example, a four-row tapered ball bearing used as a bearing for supporting rolls. The rolling bearing 10 includes two inner rings 11 , three ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com