Method for mechanically mining coal by using steep seam pseudo inclination bracing type retractable flexible shield support

A flexible shielding support and steep inclination technology, applied in cutting machinery, mine roof support, slitting machinery, etc., can solve the problems of low unit yield, low degree of mechanization, frequent vicious accidents, etc. in the working face, so as to improve the unit yield and recovery rate. , to achieve the effect of safe production and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

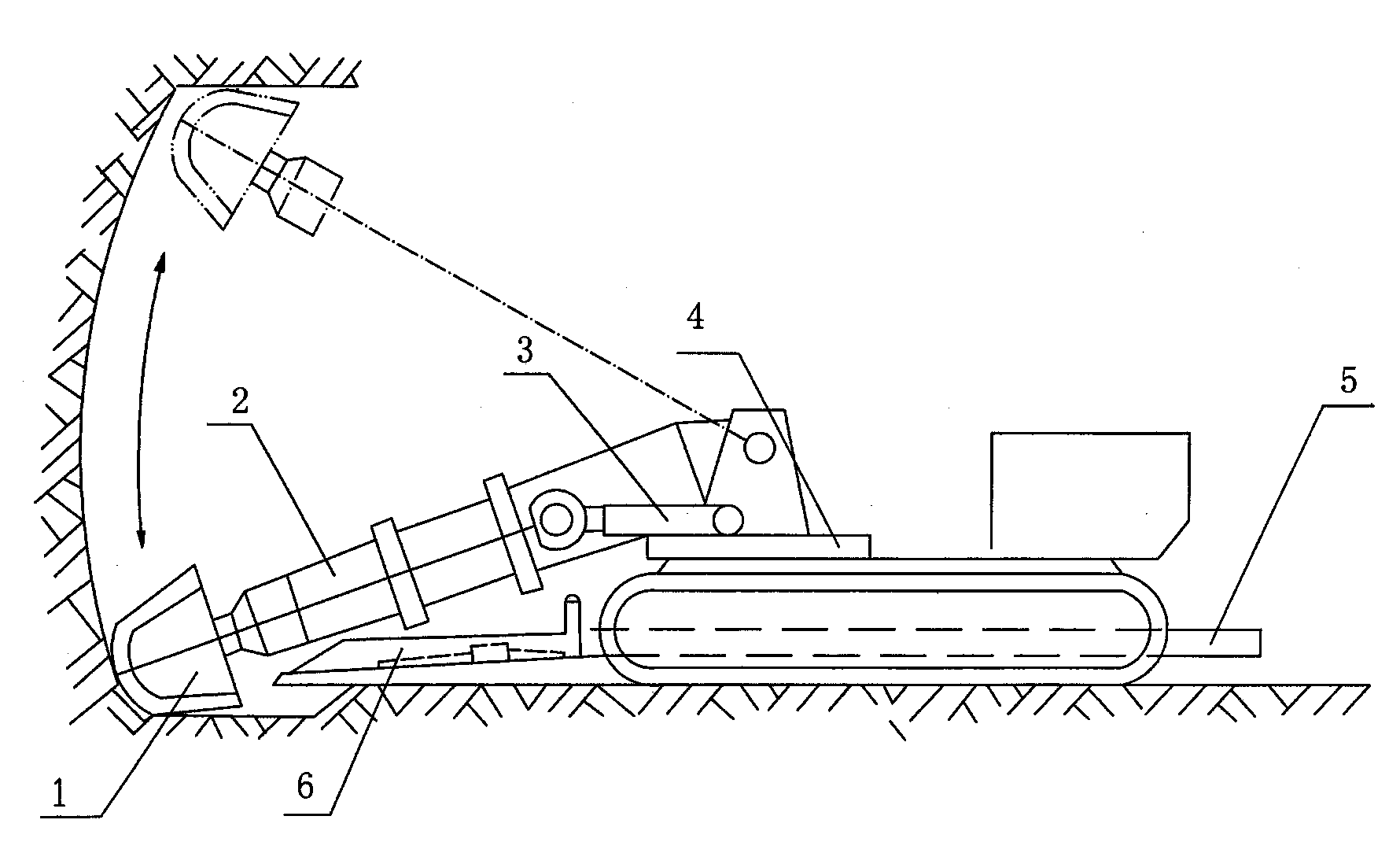

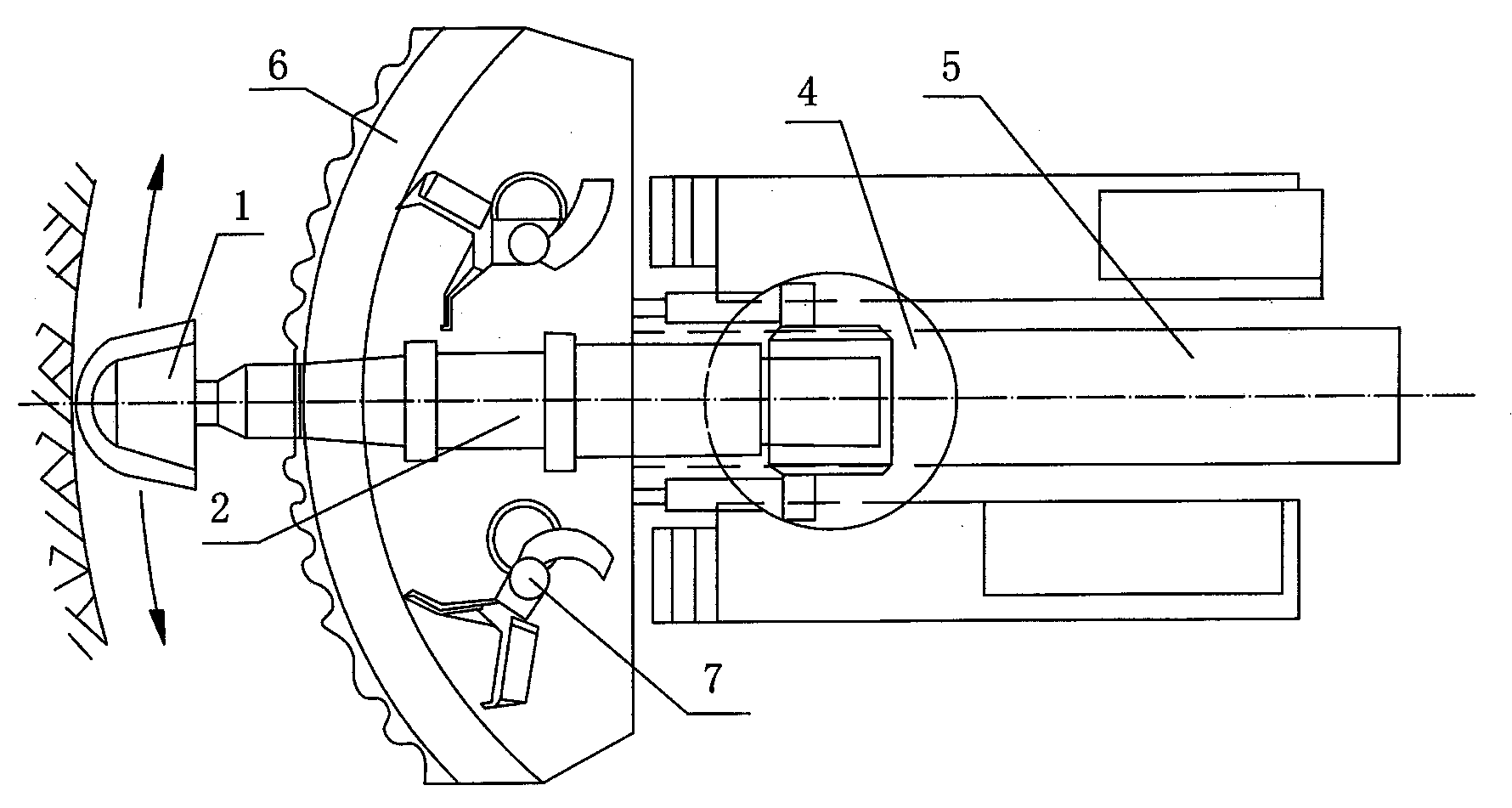

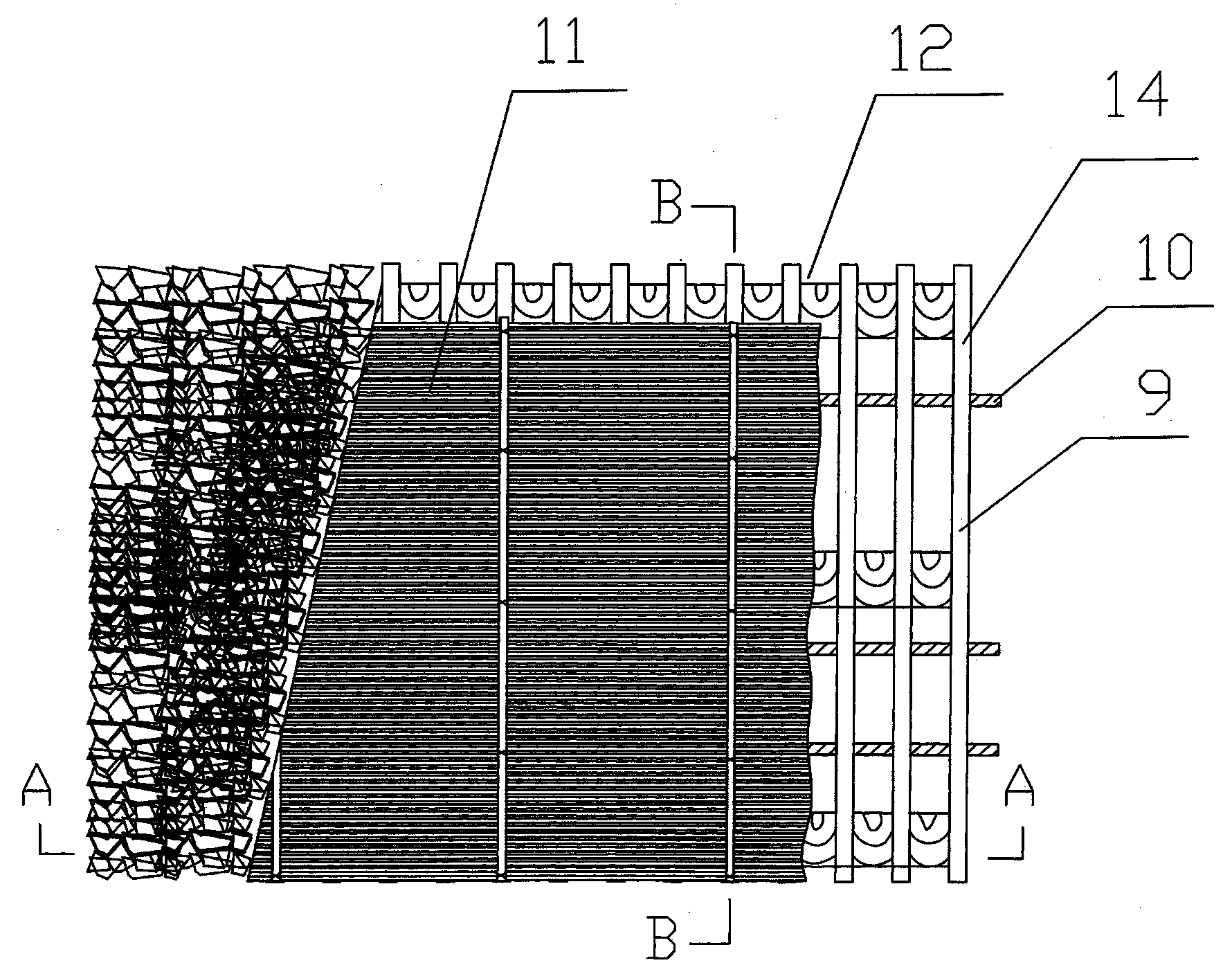

[0025] A mechanized coal mining method with a pseudo-inclined support type telescopic flexible cover support in a steeply inclined coal seam, including a shearer in a steeply inclined coal seam and a retractable support type flexible cover support 8 in a steeply inclined coal seam. The steps are as follows:

[0026] 1. Coal mining

[0027] Such as figure 1 , figure 2 , Figure 8 As shown, the comprehensive mechanized coal shearer with pseudo-slanted support type telescopic flexible cover support in steeply inclined coal seams, the cutting head 1 realizes the knife feeding through the telescopic oil cylinder 2, and the cutting head 1 of the shearer moves up and down through the lifting oil cylinder 3. Coal; through the rocker arm rotation mechanism 4 to realize the left and right swing of the rocker arm and the coal mining of the rear starting nest (during the upper triangular coal mining period).

[0028] 2. Coal shipment

[0029] The mined coal body is shoveled by the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com