Quick gel breaking process for intermediate and low temperate oil gas well fracturing fluid

A technology for fracturing fluids and oil and gas wells, applied in the direction of wellbore/well components, production fluid, drilling composition, etc., which can solve the problems of little promotion value and achieve convenient on-site operation, complete gel breaking, and flowback high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

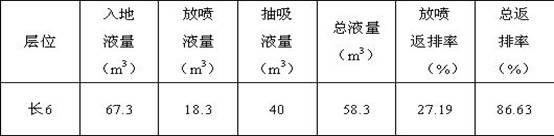

Image

Examples

Embodiment 1

[0019] A rapid gel breaking process for fracturing fluid in medium and low temperature oil and gas wells, which at least includes the following steps: 1) adding a sufficient amount of gel breaker in the pre-fluid stage; 2) reducing the use concentration of the cross-linking agent on the construction site to form a A weakly cross-linked or under-cross-linked fracturing fluid jelly; 3) At the end of the sand-carrying fluid stage, that is, when the sand addition is about to end, the gel breaker is added to the fracturing fluid in a trailing wedge shape.

Embodiment 2

[0021] According to the temperature of oil and gas wells, on the premise of ensuring that the sand-carrying fluid carrying capacity and construction safety are not affected, in the pre-fluid stage (that is, after the packer is set and before the pre-fluid stage), according to the fracturing method. It is designed to add a sufficient amount of breaker that matches the well temperature (the amount of breaker is 10 times the amount of breaker in the cross-linking fluid), and the breaker is ammonium persulfate in a conventional fracturing fluid system. The above process It is beneficial for the fracturing fluid at the far end of the fracture to break the gel quickly; when preparing the cross-linking agent solution at the construction site, reduce the mass percentage concentration of the cross-linking agent from 0.6% to 0.4% to form an under-cross-linked fracturing fluid Gelatin, this under-crosslinked fracturing fluid jelly has few chemical bonds and low crosslinking density, and t...

Embodiment 3

[0023] It is basically the same as Example 2, the difference is that in the pre-fluid stage (that is, after the packer is set and before the pre-fluid stage), a sufficient amount of breaker ( The amount of the breaker is 8 times the amount of the breaker used in the cross-linking fluid), and the breaker is potassium persulfate in the conventional fracturing fluid system; when preparing the cross-linking agent solution at the construction site, the original formula On the basis, the mass percentage concentration of the cross-linking agent was reduced from 0.7% to 0.5% to form an under-cross-linked fracturing fluid gel; in the later stage of the sand-carrying fluid stage, that is, when the sand addition was about to end, the fracturing fluid was added according to the following formula. Add 0.03%-0.05%-0.08%-0.1% mass percentage concentration of gel breaker in order from small to large in wedge shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com