Oilfield drill stem conveying device

A technology for conveying devices and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low efficiency, high labor intensity, and large labor occupation, and achieve the goal of reducing labor intensity, saving labor, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

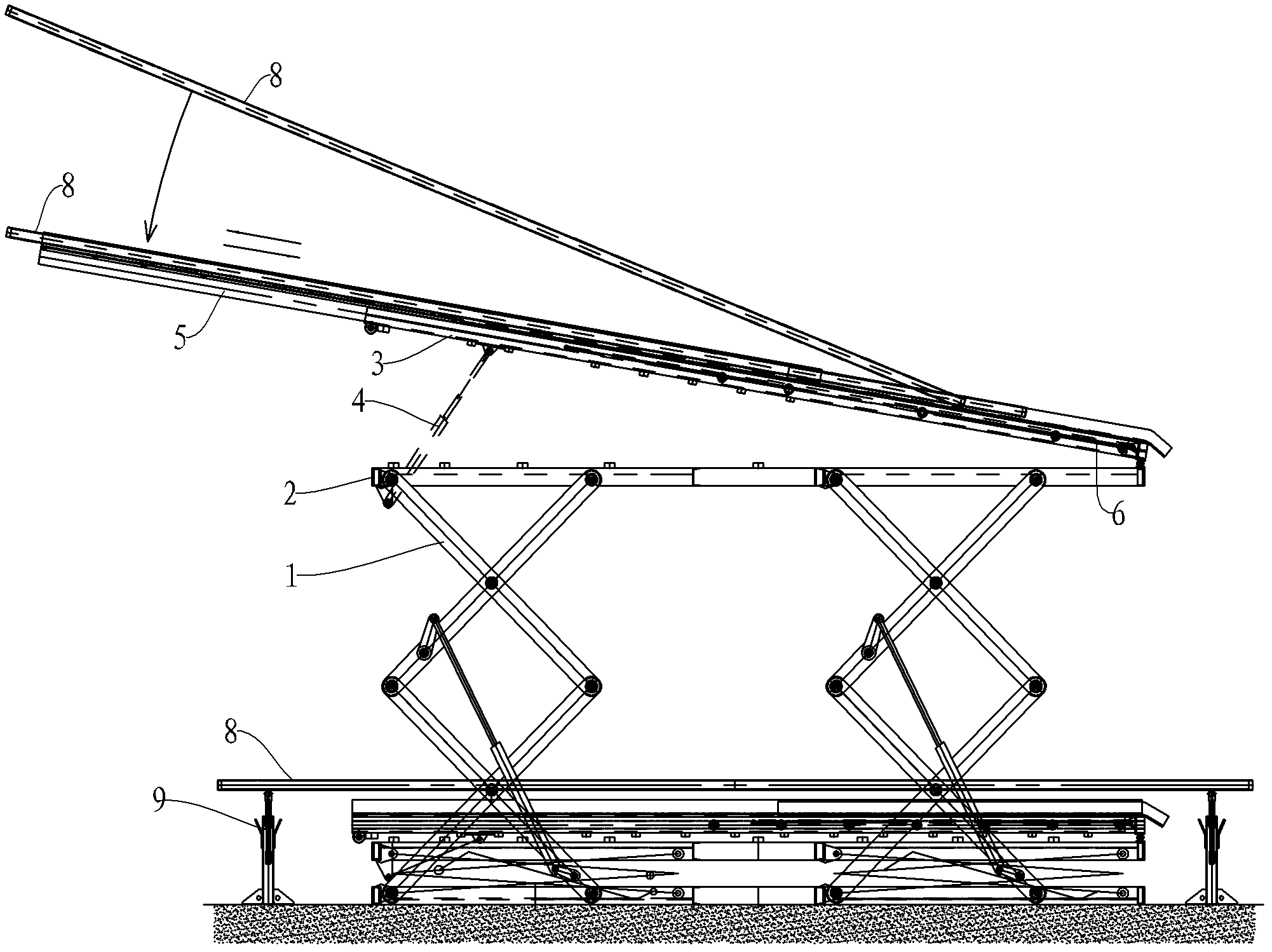

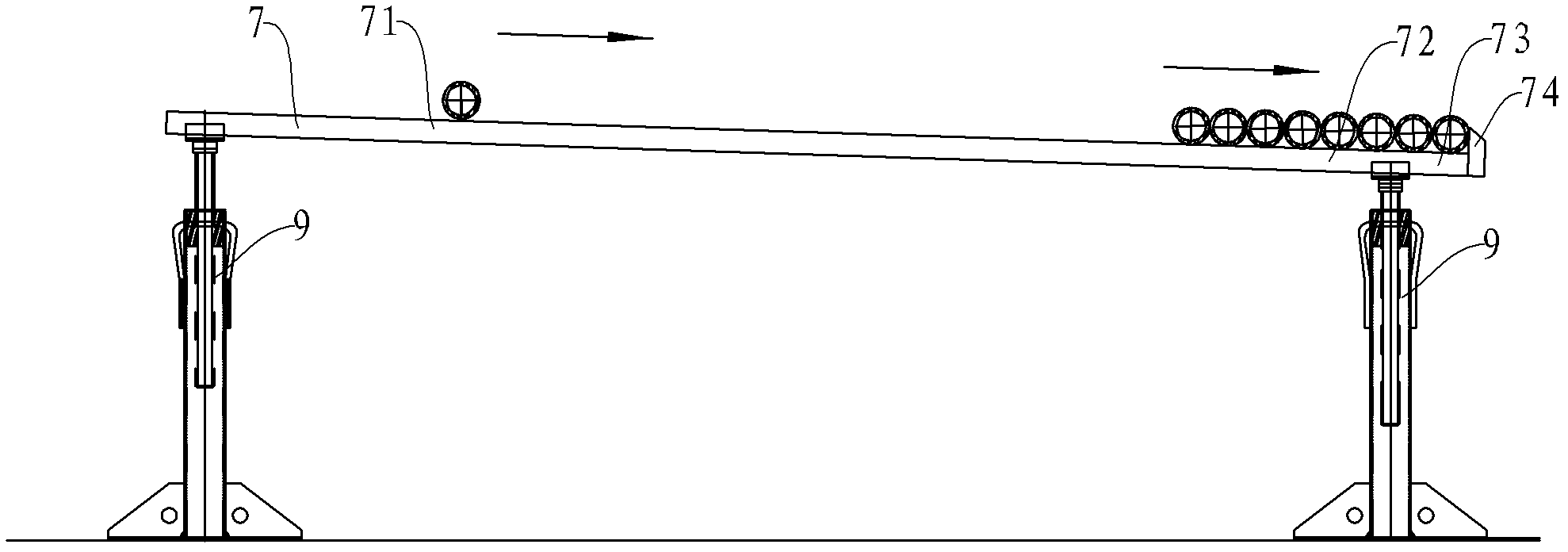

[0019] Such as figure 1 As shown, the oil field drill pipe conveying device mainly includes a scissors type horizontal lifting mechanism, an inclined lifting mechanism, and a rod feeding device.

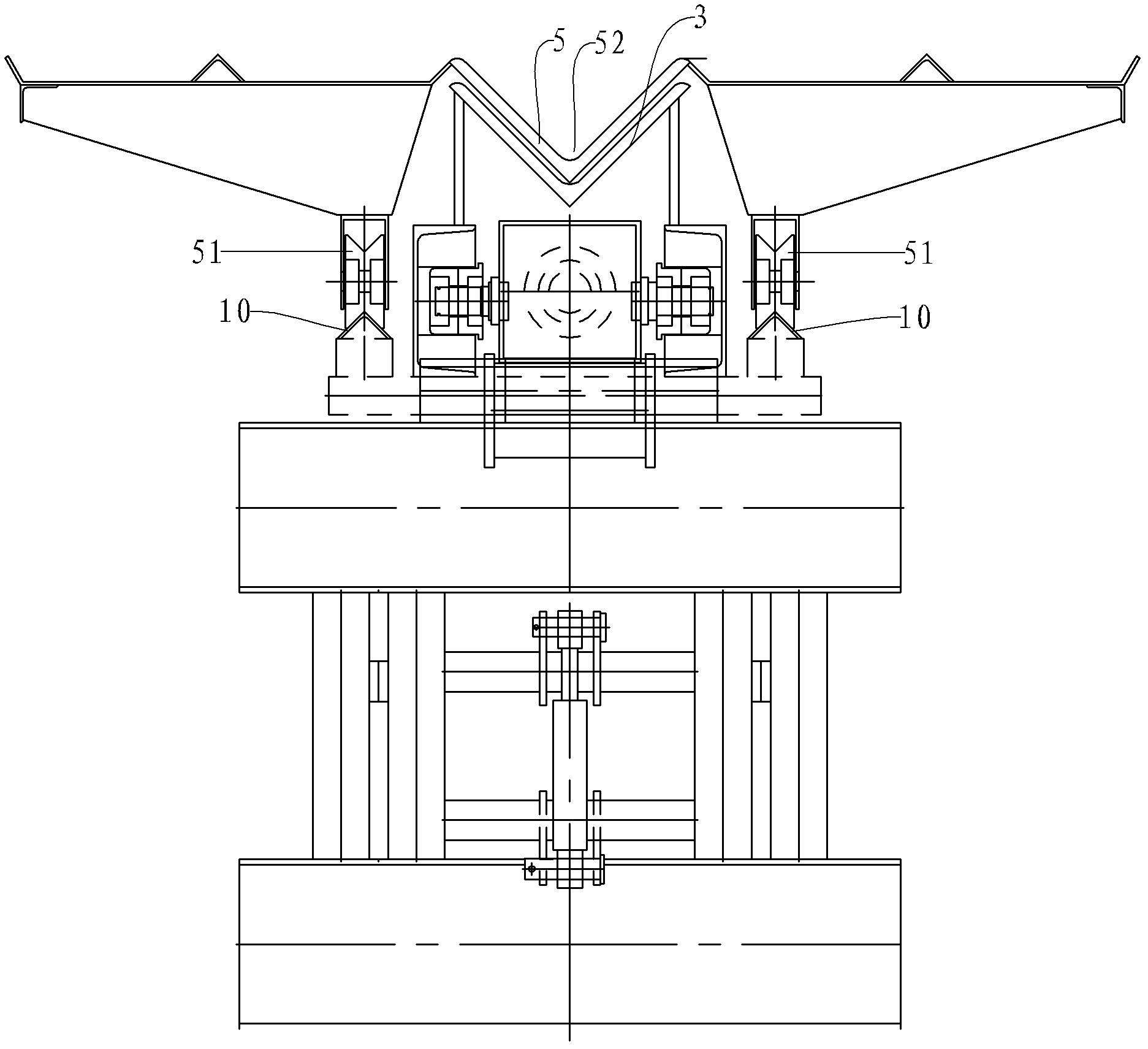

[0020] Such as figure 1 , 3 As shown, wherein, the scissors-type horizontal lifting mechanism 1 includes an upper frame assembly 2 that is horizontally arranged on the top of the scissors-type horizontal lifting mechanism.

[0021] The ramp-up mechanism includes a ramp-up bracket combination 3 and a ramp-up cylinder 4. The ramp-up bracket combination 3 is arranged above the upper frame combination 2, and the ramp-up bracket combination 3 is placed along the axial direction of the oilfield drill pipe One end is the rear end, the rear end of the ramp bracket assembly 3 is hinged with the rear end of the upper frame assembly 2, and the ramp cylinder 4 is located in front of the hinge and is arranged on the upper rack assembly 2 and the ramp bracket assembly 3 between.

[0022] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com