Cloth outlet swing mechanism

A cloth-discharging roller and cloth-roller technology, applied in the field of textile machinery, can solve the problems of difficult operation by operators, equipment damage, and increased static electricity on the cloth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

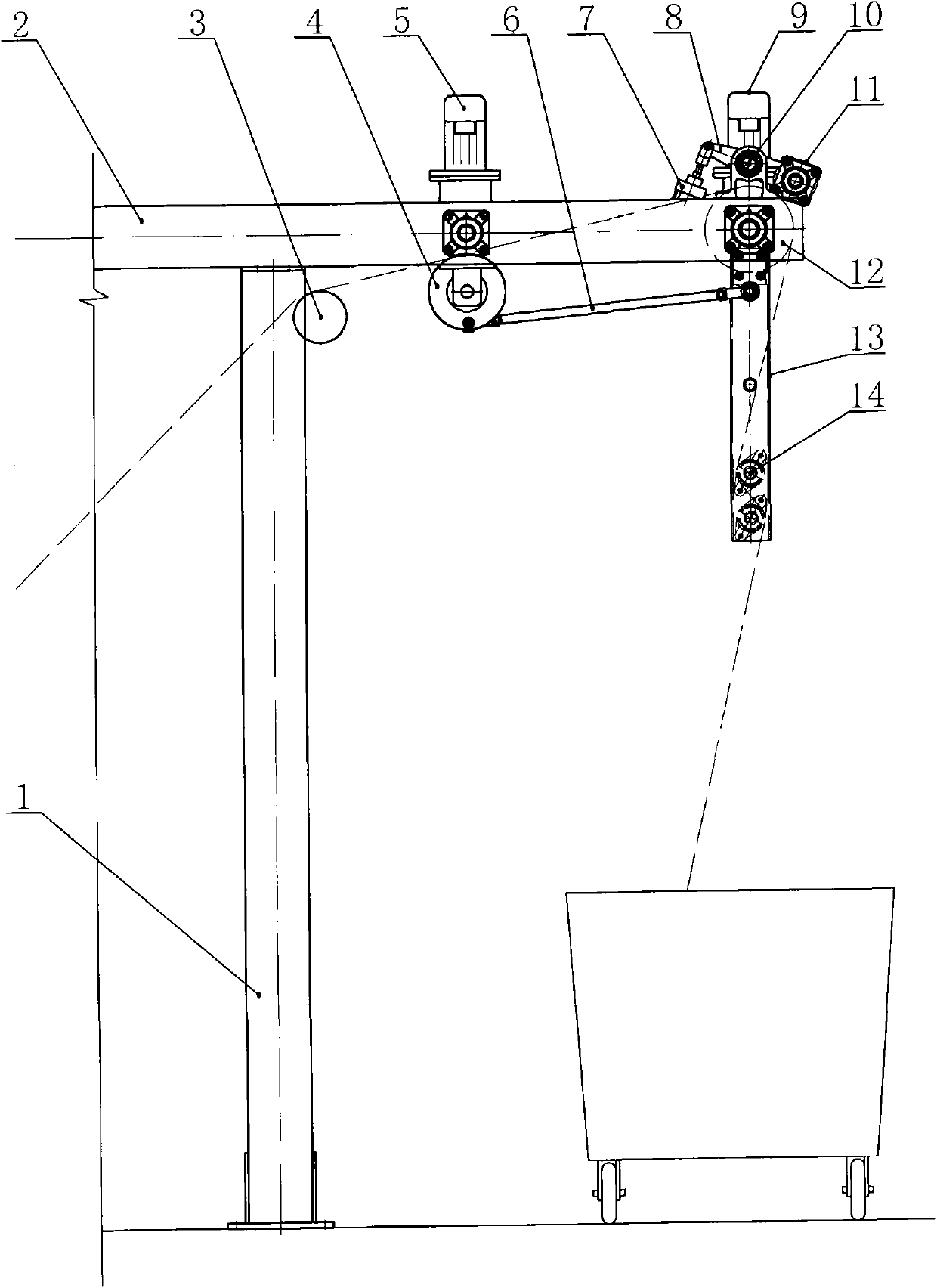

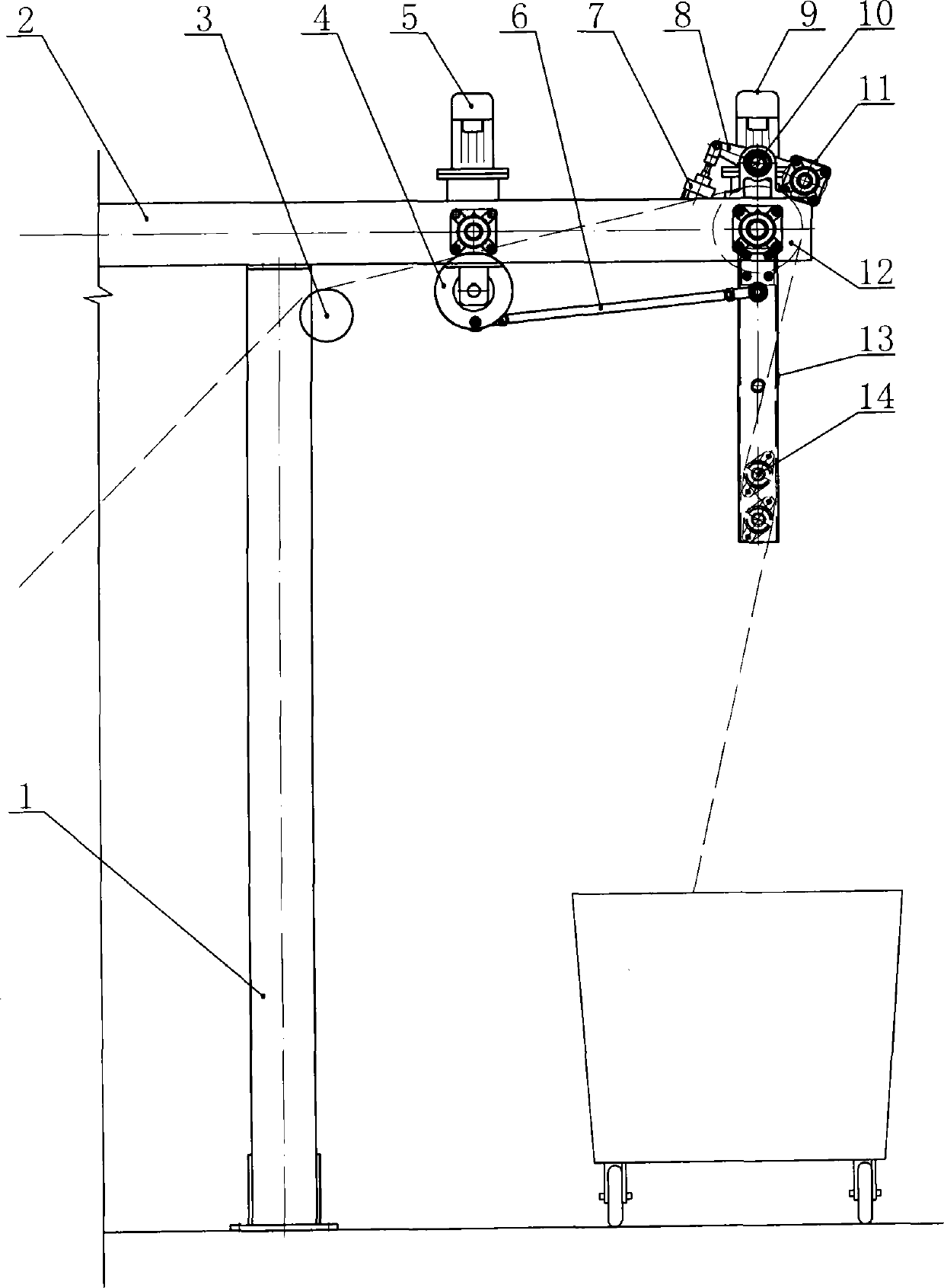

[0008] Such as figure 1 As shown, the swinging cloth delivery mechanism of the present invention includes a column 1 and a crossbeam 2 connected to the top of the column 1. A swing motor 5 and a cloth discharge motor 9 are installed on the beam 2. The swing motor 5 drives the swing wheel 4 to rotate, and the swing wheel 4 A swing arm pull rod 6 is hinged on the circumference of the swing arm pull rod 6, and the other end of the swing arm pull rod 6 is hinged on the upper end of the swing arm 13, and a cloth guide rod 14 is installed on the lower end of the swing arm 13, and the swing arms 13 on both sides are respectively hinged on the cloth outlet roller 12. Two shaft ends; the cloth outlet motor drives the cloth outlet roller 12 to rotate, the cloth outlet roller 12 is pressed with a pressure roller 11, and the two ends of the pressure roller 11 are installed with a rocker arm 8, and the middle part of the rocker arm 8 is hinged on the swing arm through a hinge shaft 10 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com