Processing method for electromagnetic shielding of magnesium alloy surface and magnesium alloy product

A technology of electromagnetic shielding and treatment method, which is applied in the field of electromagnetic shielding treatment of magnesium alloy surfaces and magnesium alloy products, can solve the problems affecting the electromagnetic shielding performance of magnesium alloys, limited improvement of corrosion resistance, rapid surface corrosion, etc., so as to improve the electromagnetic shielding effect. , Good high temperature and high humidity resistance, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) pre-coating treatment

[0050] The magnesium alloy substrate 11 is ultrasonically cleaned for about 25 minutes with absolute ethanol or isopropanone.

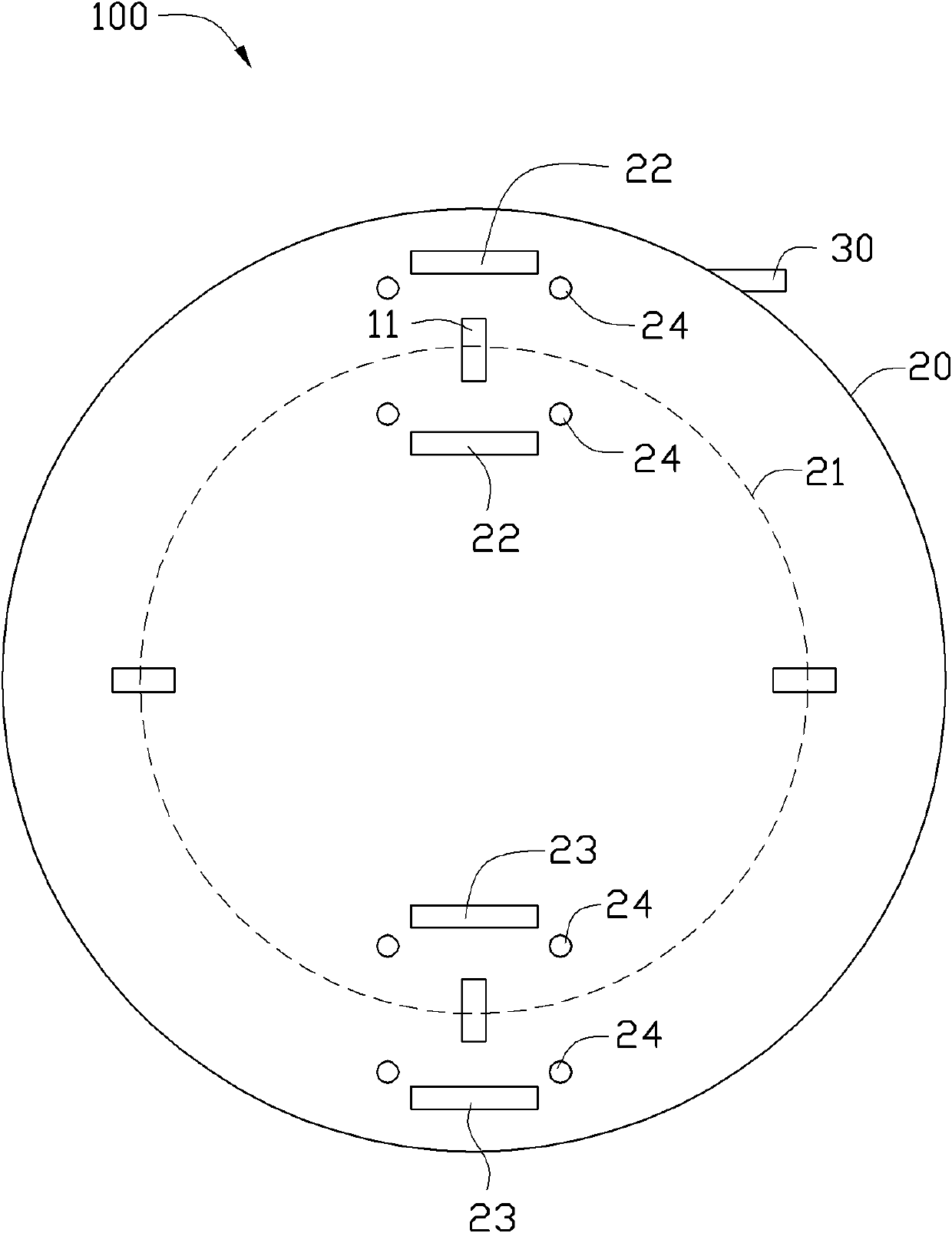

[0051] Put the cleaned magnesium alloy substrate 11 into the turntable of the vacuum coating machine 100 . The surface of the magnesium alloy substrate 11 is cleaned with argon plasma. The coating chamber 20 is vacuumized to a vacuum degree of 1.5×10 -3 Pa, the argon gas flow rate is 150sscm, the bias voltage applied to the magnesium alloy substrate 11 is -200V, and the plasma cleaning time is 5min. The vacuum coating machine used in this embodiment is produced by Beijing Danpu Surface Technology Co., Ltd., and the model is AS600DMTX05-X.

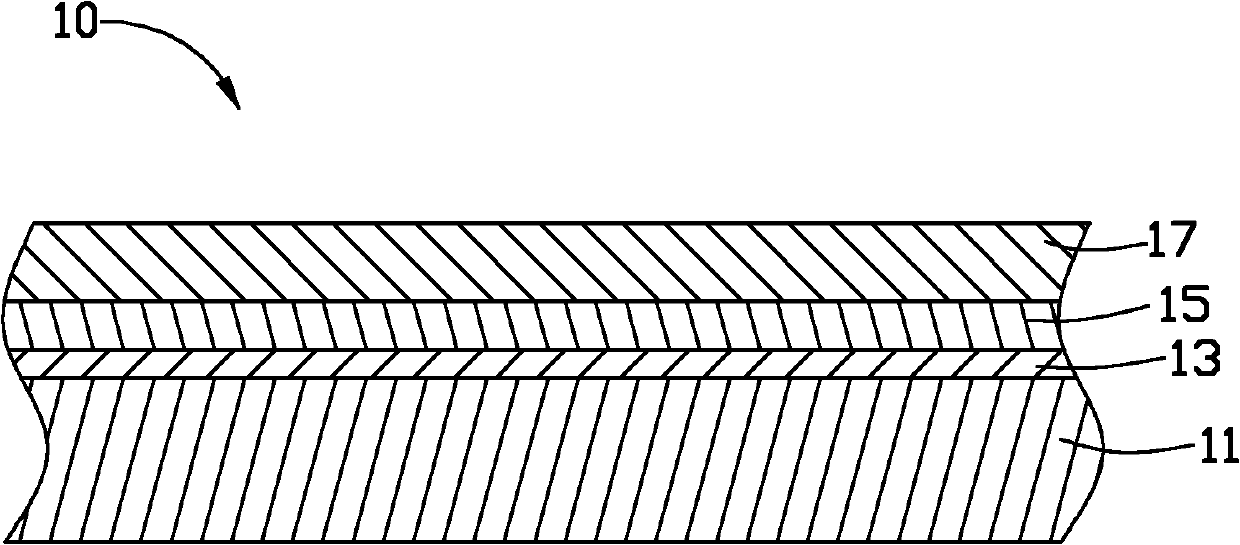

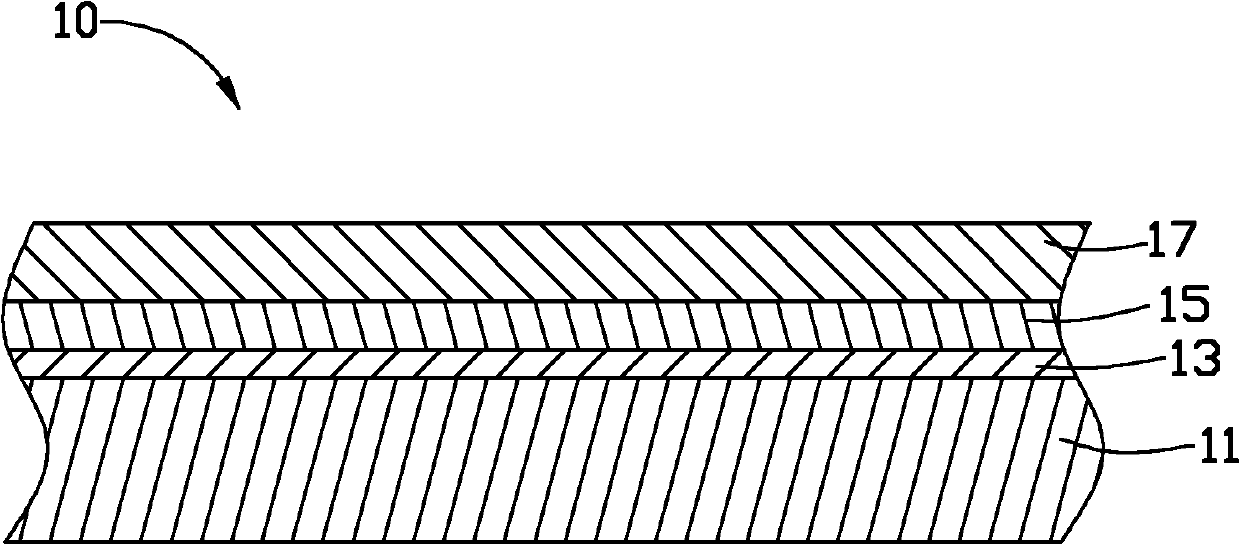

[0052] (2) Magnetron sputtering chromium metal layer 13

[0053]Keep the flow rate of the argon gas and the bias voltage applied to the magnesium alloy substrate 11 constant, heat the coating chamber to 150°C (that is, the coating temperature is 150°C), set the power of the fi...

Embodiment 2

[0060] (1) pre-coating treatment

[0061] The magnesium alloy substrate 11 is ultrasonically cleaned for about 25 minutes with absolute ethanol or isopropanone.

[0062] Put the cleaned magnesium alloy substrate 11 on the turntable of the vacuum coating machine 100 . The surface of the magnesium alloy substrate 11 is cleaned with argon plasma. The coating chamber 20 is vacuumized to a degree of vacuum of 2×10 -3 Pa, the argon gas flow rate is 200sscm, the bias voltage applied to the magnesium alloy substrate 11 is -150V, and the plasma cleaning time is 5min. The vacuum coating machine 100 used in this embodiment is produced by Beijing Danpu Surface Technology Co., Ltd., and its model is AS600DMTX05-X.

[0063] (2) Magnetron sputtering chromium metal layer 13

[0064] Keep the flow rate of the argon gas and the bias voltage applied to the magnesium alloy substrate 11 constant, heat the coating chamber from 20 to 200°C (that is, the coating temperature is 200°C), set the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com