Sludge hydrothermal drying treatment device and slurry reactor thereof

A hydrothermal reactor and treatment device technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment through temperature control, etc., can solve the problem of poor material continuity, poor reaction effect, and sludge hydrothermal dryness Low efficiency and other problems, to save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The invention provides a sludge hydrothermal drying treatment device and a slurrying reactor thereof, which can continuously perform hydrothermal drying treatment on sludge and improve the hydrothermal drying efficiency.

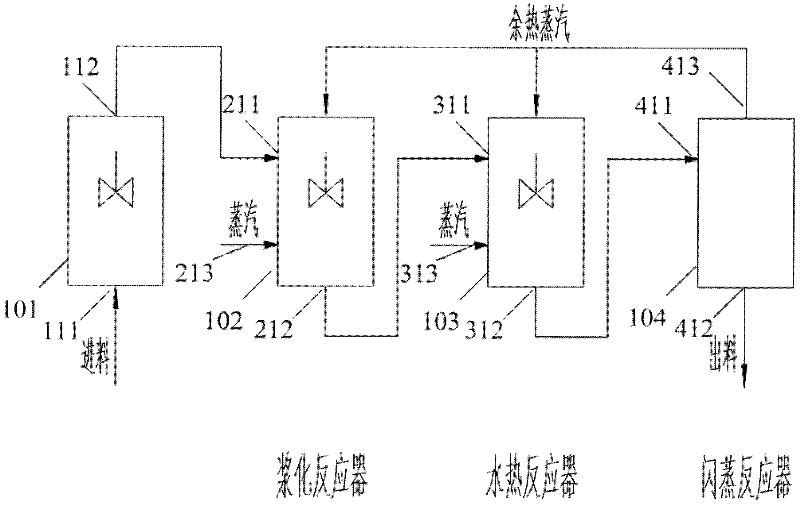

[0050] figure 1 It is a structural schematic diagram of the sludge hydrothermal drying treatment device of the present invention. Such as figure 1 As shown, the sludge hydrothermal drying treatment device of the present invention includes a homogeneous reactor 101 , a slurry reactor 102 , a hydrothermal reactor 103 and a flash reactor 104 connected in sequence.

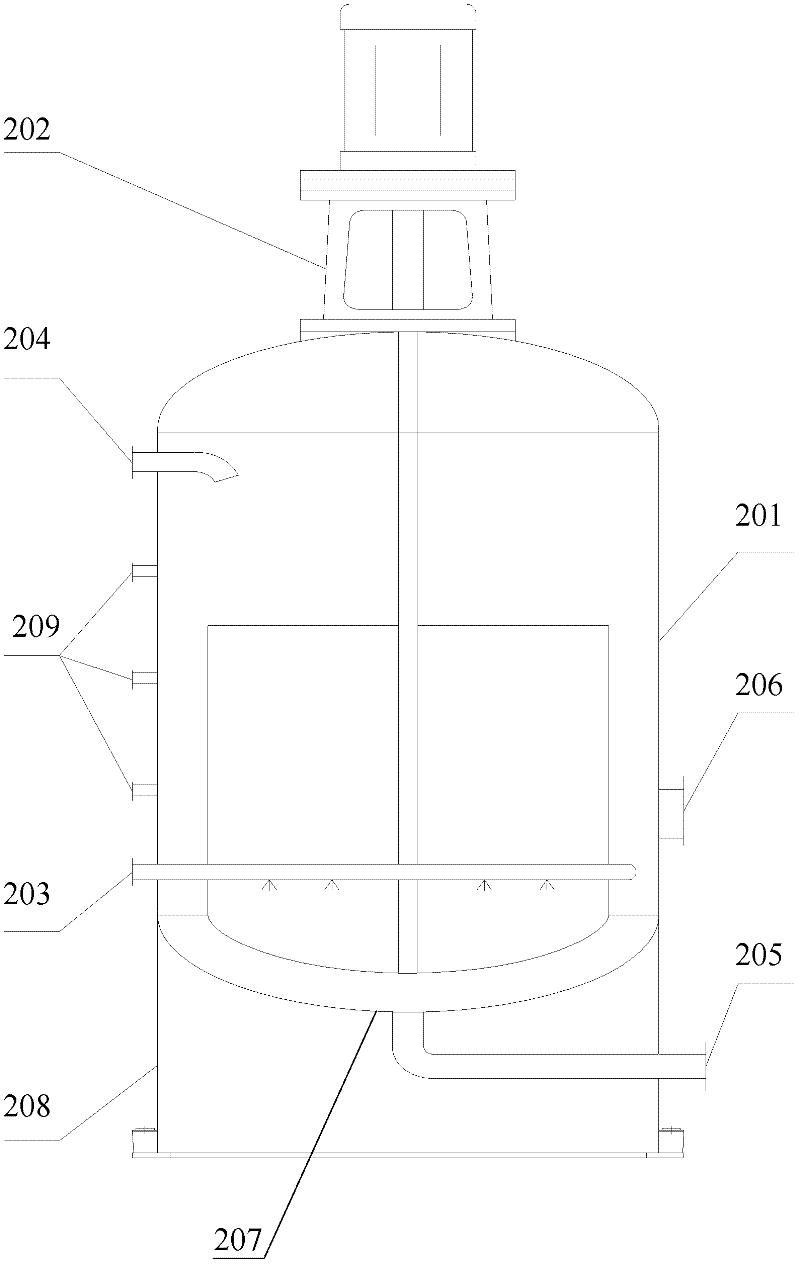

[0051] Wherein, the homogeneous reactor 101 includes a first reactor tank and a first agitator extending into the first reactor tank. The first material inlet 111 of the homogeneous reactor 101 is arranged at the bottom of the first reactor tank body, and the first material outlet 112 is arranged at the upper part of the side wall of the first reactor tank body. The sludge material is input...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com