Method for dephosphorizing low-phosphorus ammonium tungstate solution

A low-phosphorus ammonium tungstate and ammonium tungstate technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of difficult calcium carbonate removal of phosphorus, increased production costs, and large consumption of calcium carbonate. The effect of cheap price, loss reduction, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

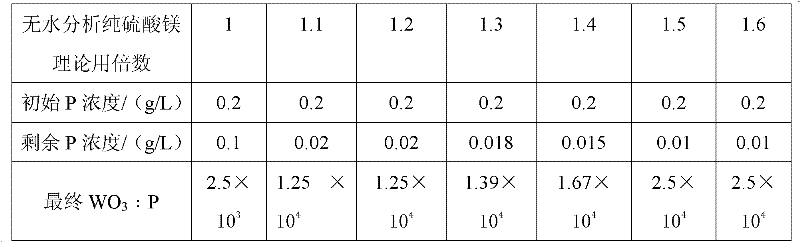

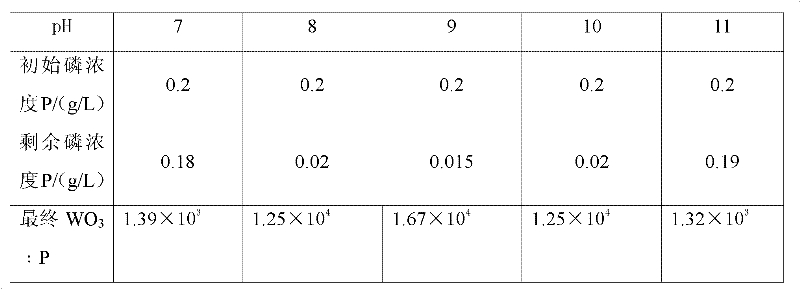

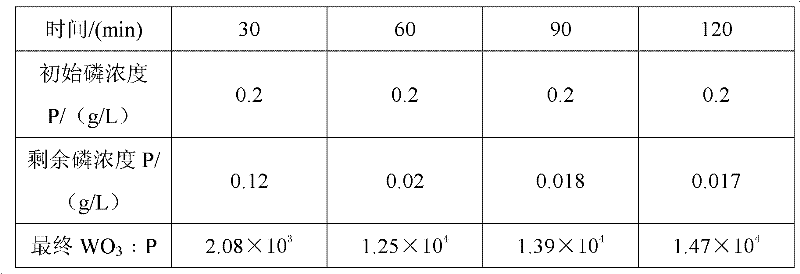

[0010] The black and white mixed tungsten ore is first ball milled to make the particle size of the tungsten concentrate reach -320 mesh ≥ 98%, and then the slurry is pumped into the autoclave for decomposition by adding phosphate and low alkali, and after filtration, a high-concentration sodium tungstate solution is obtained, and the high-concentration tungsten After diluting the sodium phosphate solution to prepare the pre-delivery solution, carry out ion exchange dephosphorization and transform into a high-concentration ammonium tungstate solution. At this time, anhydrous analytically pure magnesium sulfate is added for dephosphorization. The process conditions are as follows: the amount of anhydrous analytically pure magnesium sulfate is 1.1-1.5 times the theoretical dosage, pH value 8-10, reaction time 1 hour, reaction temperature normal temperature.

[0011] 1. Anhydrous analysis of the effect of the amount of pure magnesium sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com