Inkless laser ecological printing method

A laser and ecological technology, applied in printing and other directions, can solve problems such as deterioration of living environment, impact on recycling and environmental protection, and impact on human health, and achieve reduced processing costs, good low-carbon energy-saving effects, social benefits, and convenient preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Ecological laser printing method

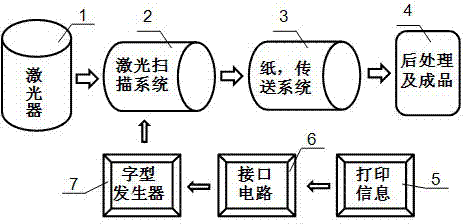

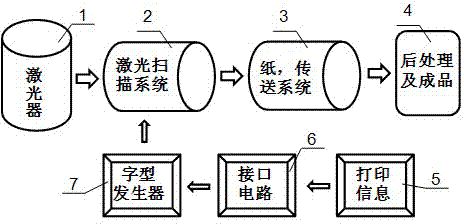

[0027] The flow of the eco-laser printing method is as follows: figure 1 shown. On the basis of inheriting the current laser printing method, it is mainly composed of laser generation and control system (1, 2), paper feeding system 3) and printing information system (5-7). Therefore, there is no need for the powder grain and forming and fixing system in the current laser printing technology; the laser with the above characteristics and the corresponding control device are selected; in this way, the laser is directly focused on the printing paper during printing, and the surface of the printing paper is discolored or ablated by high temperature. form text or patterns.

Embodiment 2

[0028] Embodiment 2 The laser system of ecological laser printing device

[0029] The laser beam emitted by the laser is injected into the acousto-optic deflection modulator through the reflector. At the same time, the binary graphic dot matrix information sent by the computer is sent from the interface to the font generator to form the binary pulse of the required font. Information, the signal generated by the synchronizer controls the high-frequency oscillator group, and then is added to the acousto-optic modulator through the frequency synthesizer and power amplifier to modulate the laser beam injected by the mirror. The modulated light beam is injected into the multi-faceted rotating mirror, and then the beam is focused by the wide-angle focusing lens and then shot to the surface of the printing paper, so that the angular velocity scanning becomes linear velocity scanning, and the entire scanning process is completed. At the same time, vertical scanning is realized by the ...

Embodiment 3

[0030] Embodiment 3 Example of simulated laser printing

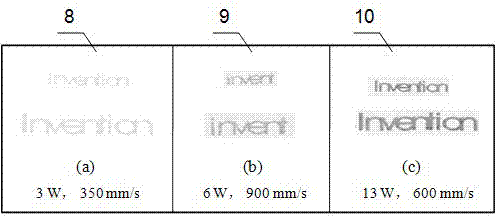

[0031] By controlling different laser power and irradiation time (or scanning speed), simulated laser printing on ordinary printing paper can be obtained as follows: figure 2 clearly visible text or numbers. It is not completely black, but a kind of yellowish text: when the power is low, the color is bright yellow (such as figure 2 a), when the power is high, the color is golden (such as figure 2 b, 2c). Therefore, different printing effects can be achieved to a certain extent by adjusting the parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com