Resin Encapsulation Apparatus And Resin Encapsulation Process

A resin sealing device and resin sealing technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of semiconductor component damage, poor yield, etc., to achieve suppression of driving force, high productivity, and short forming cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

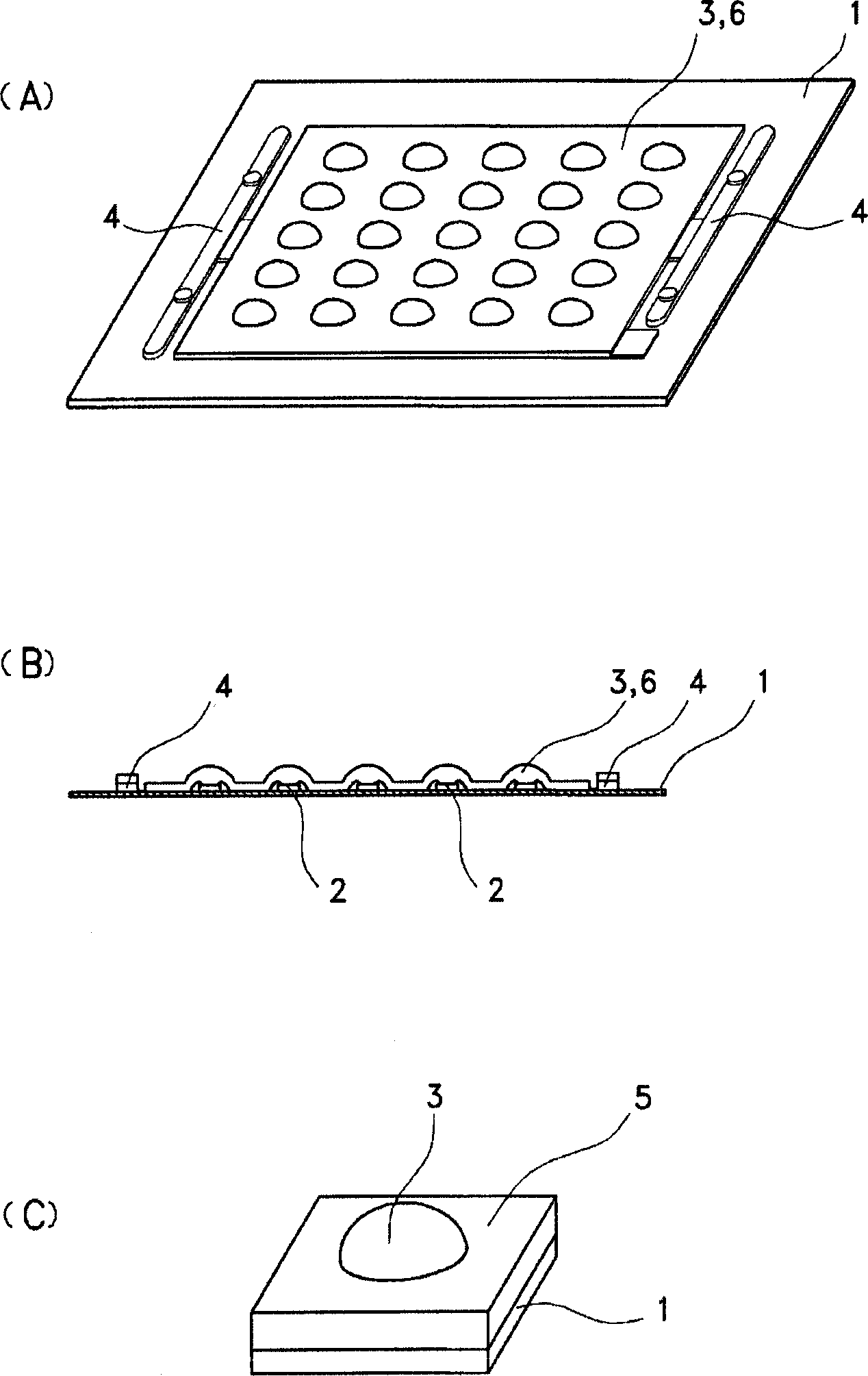

[0086] refer to Figure 1 to Figure 14 The accompanying drawings illustrate embodiments of the resin sealing device of the present invention.

[0087] like figure 1 (A), figure 1 As shown in (B), the resin sealing device of this embodiment is a device for resin sealing an optical semiconductor element 2, such as an LED, mounted on a ceramic substrate 1 printed with a conductive pattern at a predetermined pitch. on one side.

[0088] As the resin sealing material for resin-sealing LEDs according to the present embodiment, a silicone material excellent in heat resistance and translucency is used as a main raw material. This above-mentioned resin sealing material is not only a solid material called a tablet (tablet) that has been used all the time, but also can obtain a desired shape by injecting a liquid resin sealing material into a mold, heating it, and thermally curing it. shape. For example, in the present application, the molded product 3 including a surplus resin (Jap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com