Auxiliary heating device for post-curing of die assembly for wind turbine blade production

A technology of wind power generation blades and auxiliary heating, which is applied in applications, household components, household appliances, etc., and can solve problems such as impossible to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

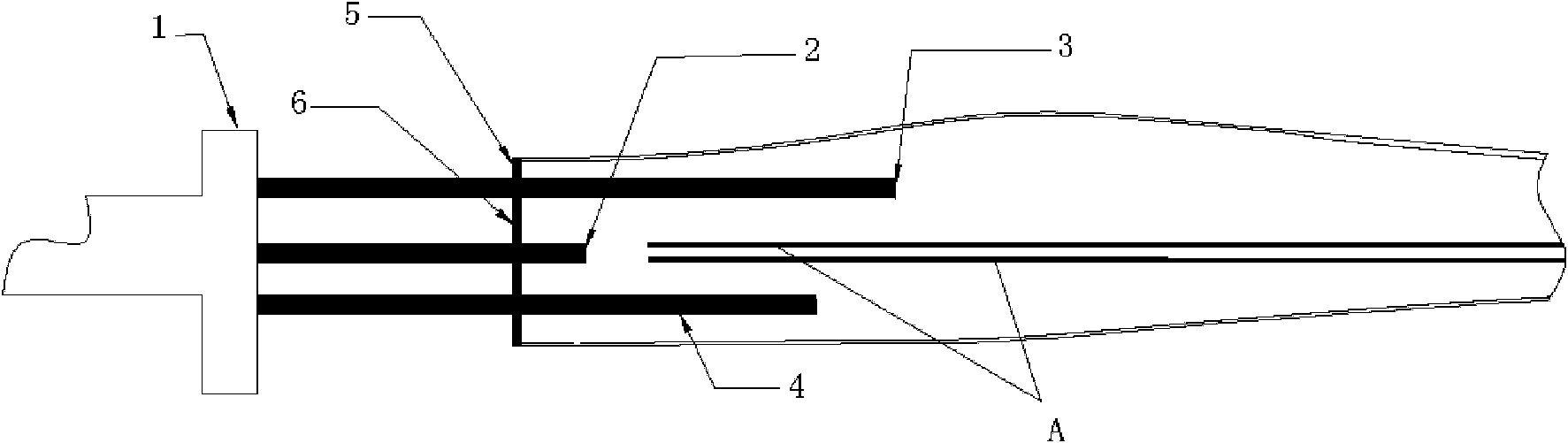

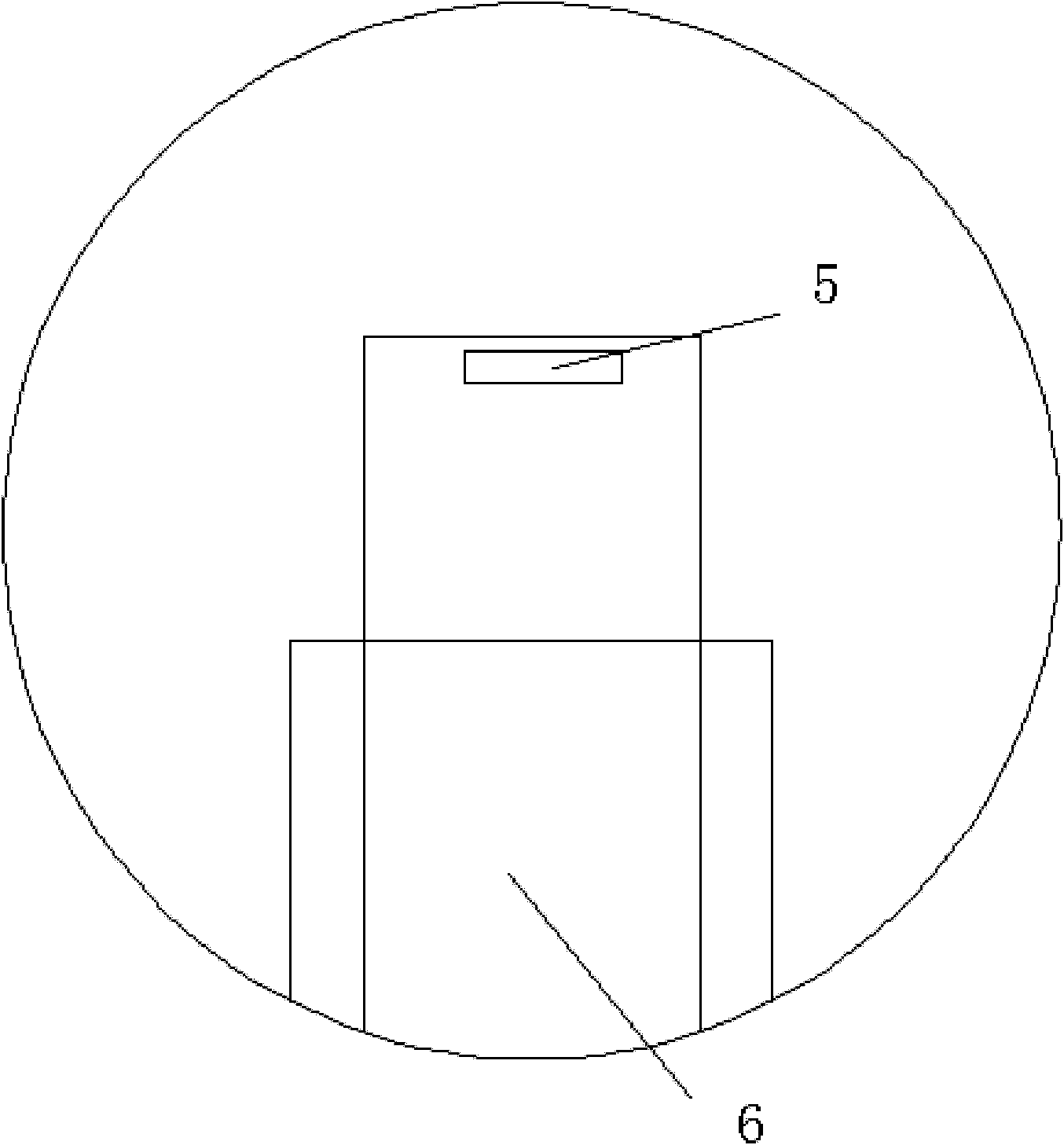

[0014] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a hot air blower 1 arranged at the root end of the web A; the hot air blower 1 is connected to the first heating pipe 2, the second heating pipe 3 and the third heating pipe 4; the first heating pipe The tube 2, the second heating tube 3 and the third heating tube 4 pass through the hole 6 of the root baffle plate 5 placed at the root end of the web A; the first heating tube 2 is behind the root end of the web A, and the first heating tube 2 The front end of the second heating pipe 3 is 0.9m-1.1m away from the root end of the web A; the second heating pipe 3 is above the root end of the web A, and the front end of the second heating pipe 3 is 5m-7m away from the root end of the web A; the third The heating pipe 4 is below the root end of the web A, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com