Rubber mixing Mooney viscosity on-line soft-measuring method

A Mooney viscosity and rubber mixing technology, which is applied in the field of rubber machinery and industrial automation control, can solve the problems of uncertainty, Mooney viscosity value hysteresis, time-consuming and labor-intensive problems, so as to reduce hysteresis, improve production quality and Efficiency and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

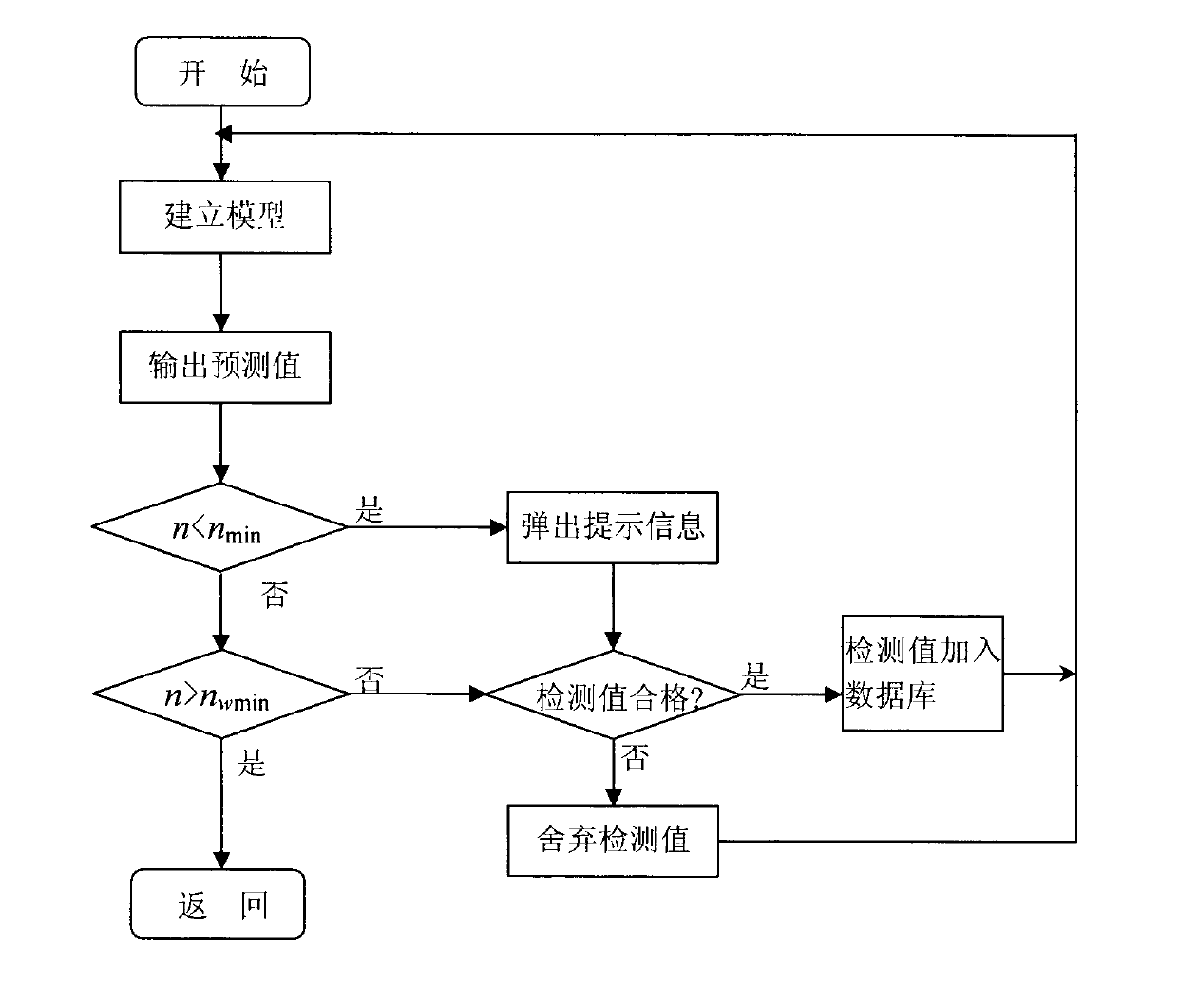

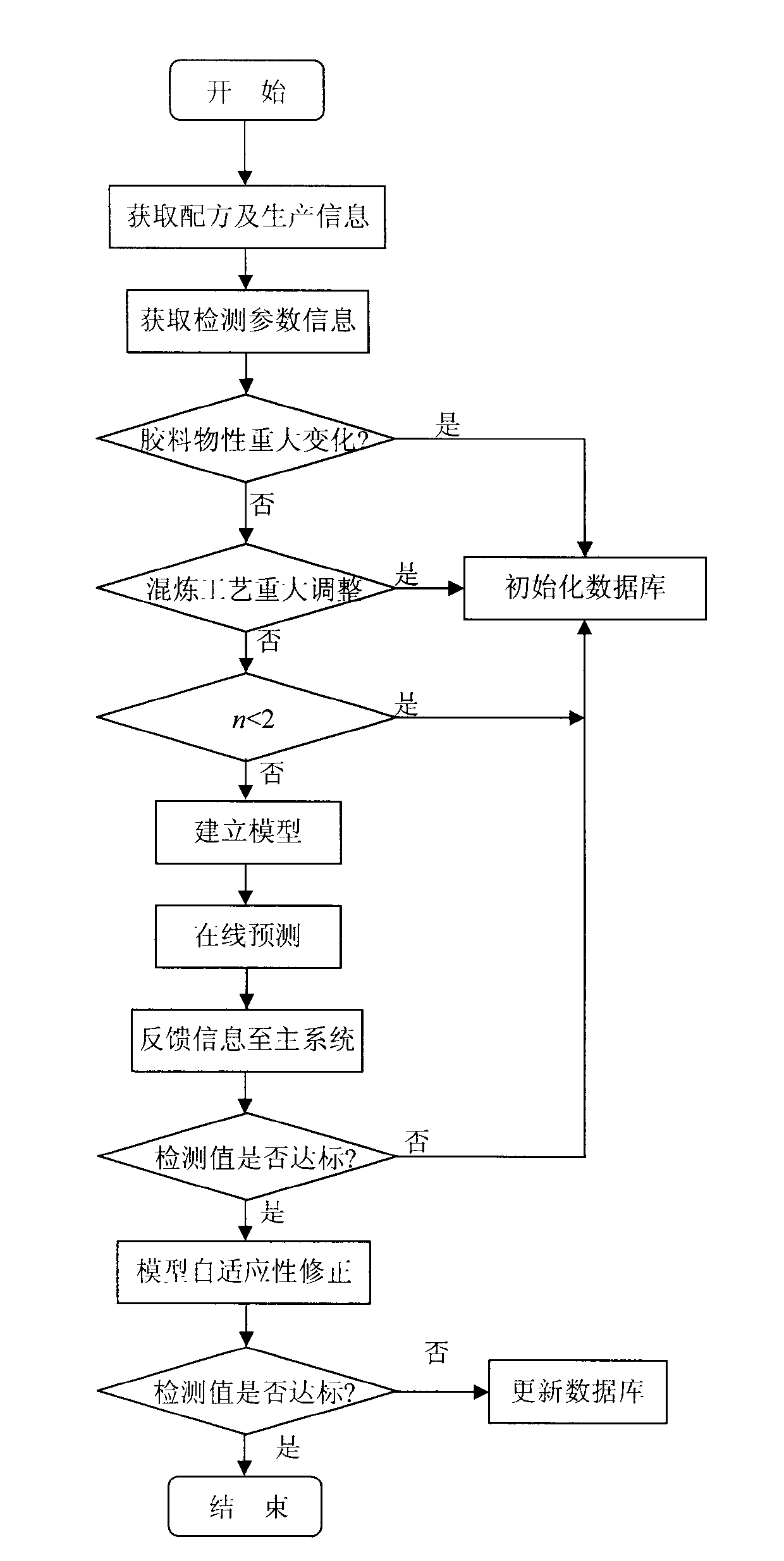

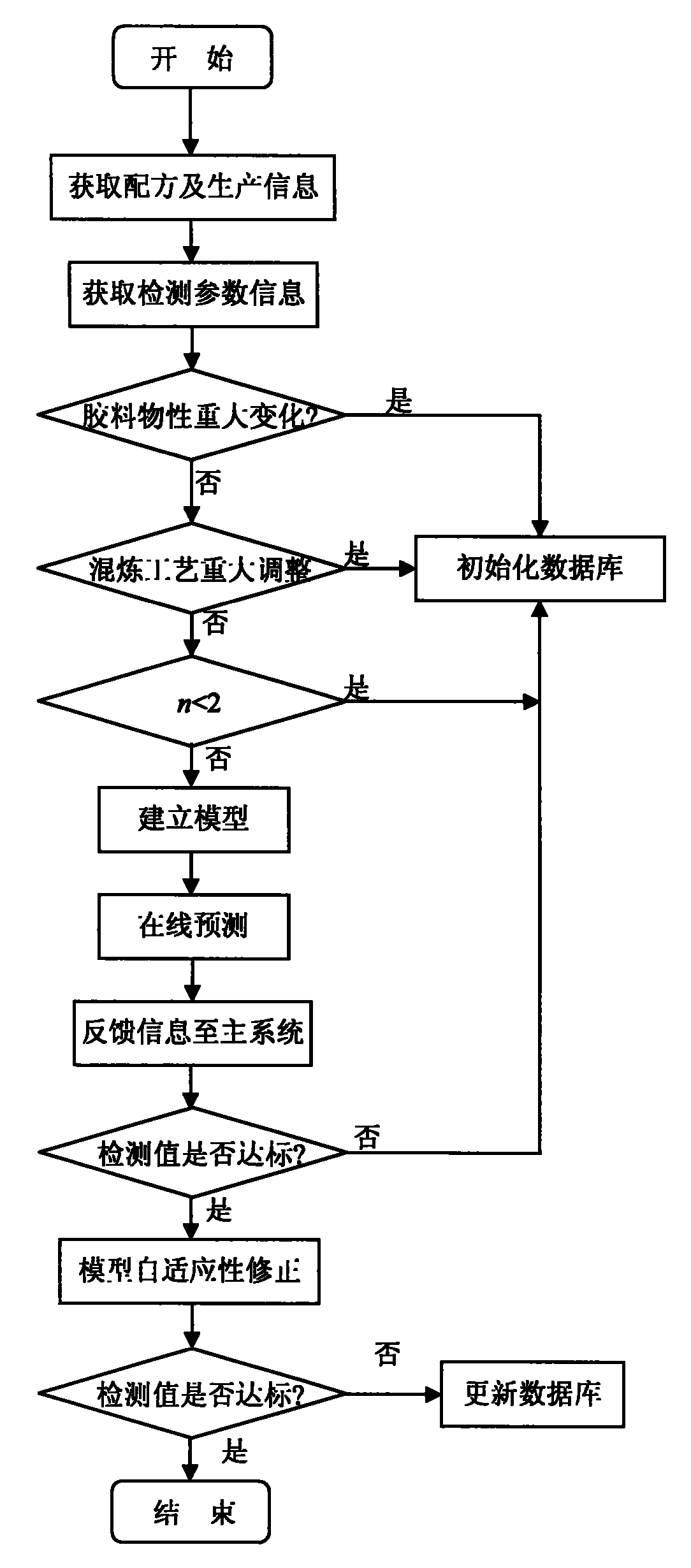

[0050] Example 1, such as figure 1 and figure 2 As shown, the online soft measurement method of rubber mixing Mooney viscosity is to take the first sample and detect it during the mixing process of the rubber material through banburying, extrusion, calendering, and kneading.

[0051] Specifically, the support vector machine function K(x i , x j )=i ), φ(x j )> to establish the Mooney viscosity prediction model;

[0052] On-line sampling operation is carried out after the mixed rubber material of the i-th car passes through the extrusion process and before the release agent;

[0053] For the first sample test of the rubber sample after sampling, the Mooney viscosity value is counted as x i ;

[0054] will x i Introduce the Mooney viscosity prediction model to predict the Mooney viscosity value Y of the i-th vehicle rubber sample detected by the conventional air-cooled parking process through the mapping relationship f: x→y i .

[0055] For the predicted Mooney viscosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com