Multilayered workpiece machining positioning mechanism of edge milling machine

A technology of positioning mechanism and edge milling machine, which is applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of difficult guarantee of product accuracy, inconvenient processing, low efficiency, etc., to avoid artificial measurement errors, structure Simplicity and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

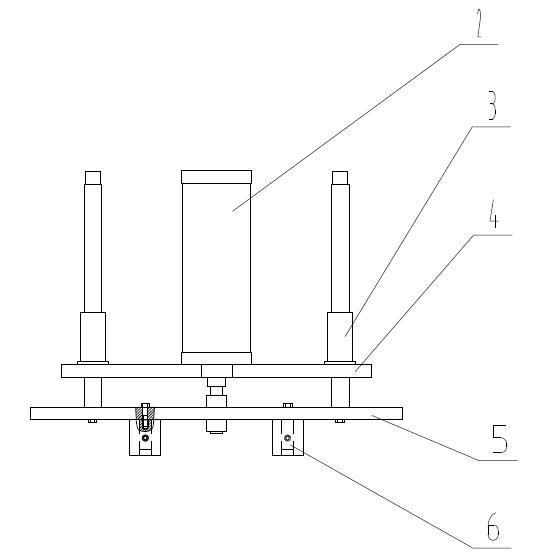

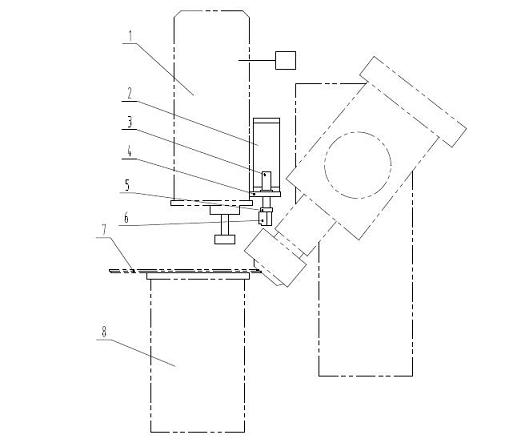

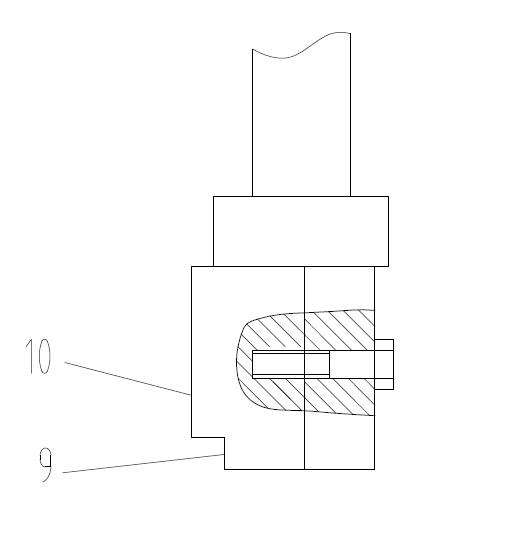

[0013] Depend on Figure 1-3 From the shown embodiment, it can be seen that it includes a piston actuator 2, a seat plate 4, a guide post and a guide sleeve 3, a connecting plate 5 and a positioning block 6, and the cylinder body of the piston actuator 2 is fixedly connected with the beam 1 of the edge milling machine. The seat plate 4 is vertically and fixedly connected to one end of the cylinder body; the connecting plate 5 is parallel to the seat plate 4 and is connected to the piston rod of the piston actuator 2; the positioning block 6 is connected to the connecting plate 5; the guide post guide sleeve 3 is fixedly connected to the Between the seat plate 4 and the connecting plate 5; the middle part of the seat plate 4 is provided with a round hole suitable for the piston rod, which is fixedly connected with one end of the cylinder piston rod; the middle part of the connecting plate 5 is connected to the piston rod of the piston actuator 2 connection; two positioning bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com