Method for producing planographic printing plate precursor

A technology for lithographic printing plates and original plates, which is used in the field of preparing negative-type lithographic printing plate original plates to achieve the effects of improving on-machine developability and improving developability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

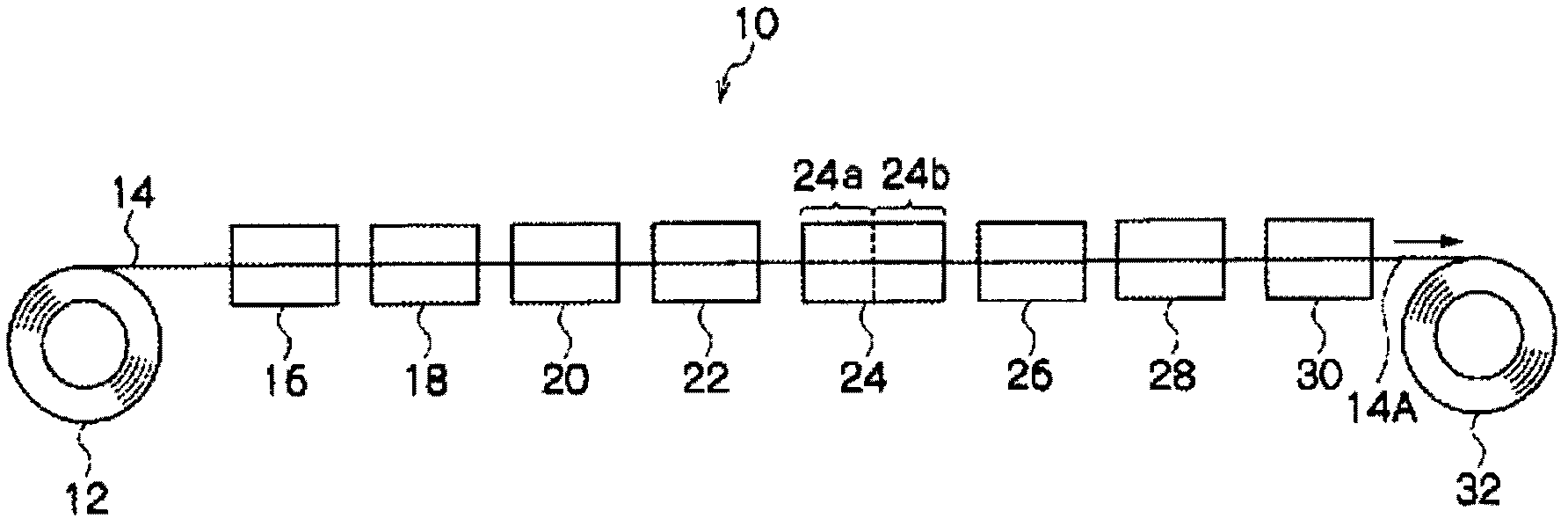

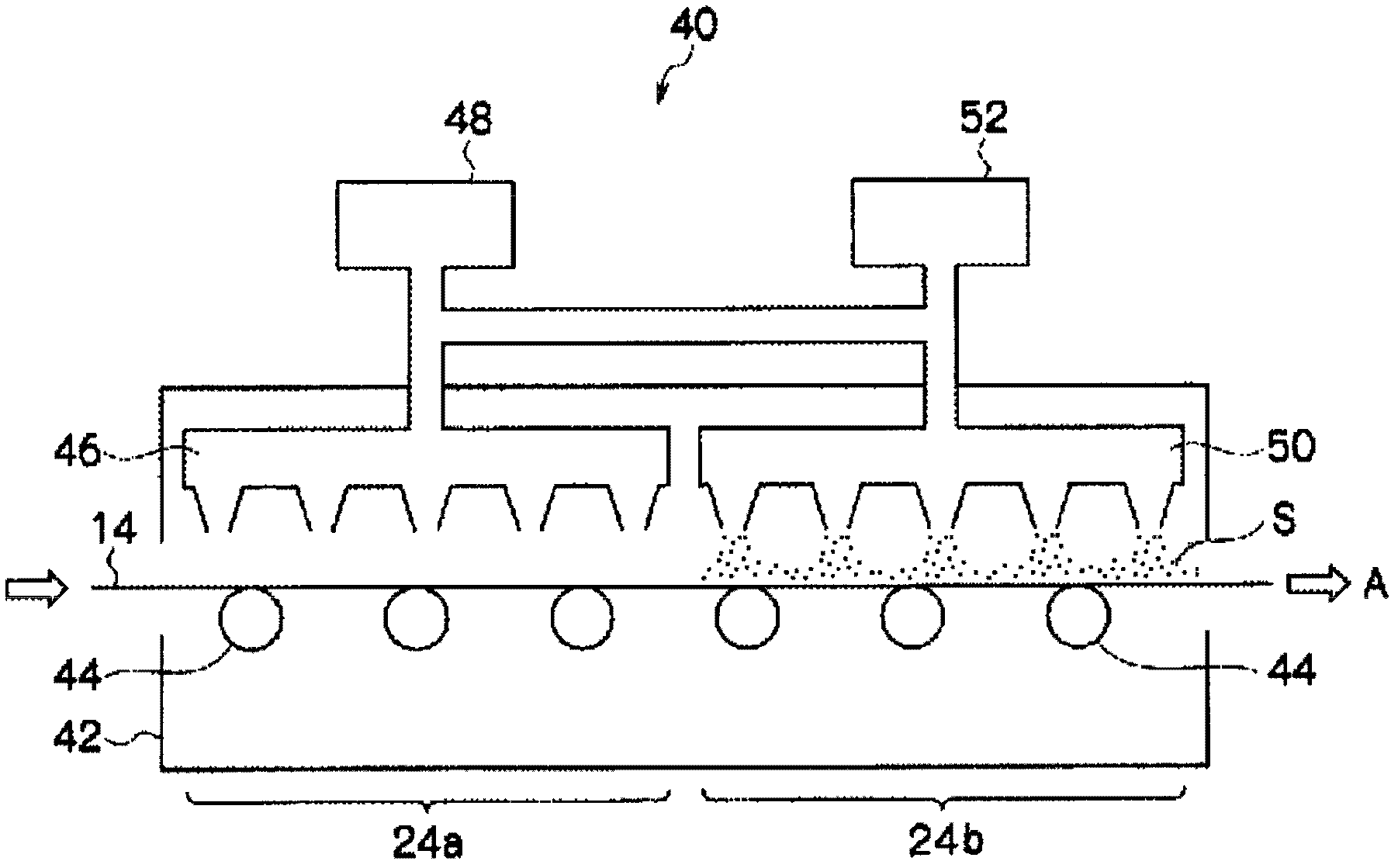

preparation example Construction

[0175] [About the production method other than the image-recording layer]

[0176] [Coating and drying of top coat]

[0177] After that, in the overcoat coating and drying unit 26, an overcoat (PVA coating film) containing a water-soluble polymer having a hydrogen bonding group, for example, PVA (polyvinyl alcohol) as a main composition is formed. As for the coating method, the same coating method as that used for forming the back coat layer, undercoat layer or image recording layer can be employed.

[0178] Examples of water-soluble polymers having hydrogen-bonding groups contained in the overcoat include polyvinyl alcohol, partial esters, ethers, and acetals thereof, and unsubstituted ethylene in an amount sufficient to impart the desired water-solubility to the copolymer. Copolymers of alcohol units. As polyvinyl alcohol, those hydrolyzed by 71 to 100 mol % and having a degree of polymerization in the range of 300 to 2,400 are exemplified. In detail, for example, PVA-105...

Embodiment 1 to 12 and comparative example 1 to 2

[0247] [Preparation of Lithographic Printing Plate Master]

[0248] (1) Preparation of carrier (No. 1)

[0249] An aluminum plate (material: JISA 1050) having a thickness of 0.3 mm was degreased at 50° C. for 30 seconds using a 10% by weight aqueous solution of sodium aluminate to remove rolling oil on its surface, and then three Nylon brush with nylon bristles of 0.3 mm and an aqueous suspension of pumice with a median size of 25 μm (specific gravity = 1.1 g / cm 3 ) Graining the surface of the aluminum plate, and then fully washing with water. The plate was etched by dipping in 25 wt% aqueous sodium hydroxide solution at 45°C for 9 seconds, washed with water, then dipped in 20 wt% nitric acid solution at 60°C for 20 seconds, and washed with water. The amount of etching on the grained surface is about 3g / m 2 .

[0250]Then, the electrochemical roughening treatment was continuously performed on the plate using an alternating current of 60 Hz. The electrolytic solution used ...

Embodiment 21 to 34 and comparative example 11 and 12

[0309] [Preparation of Lithographic Printing Plate Master]

[0310] (1) Formation of image recording layer

[0311] A coating liquid (2) for an image-recording layer shown below was coated on the support having the above-mentioned undercoat layer using a bar coater. The coated image-recording layer was dried under the conditions described in Table 2 to confirm properties. The dry coating amount of the image recording layer is 1.1 g / m 2 .

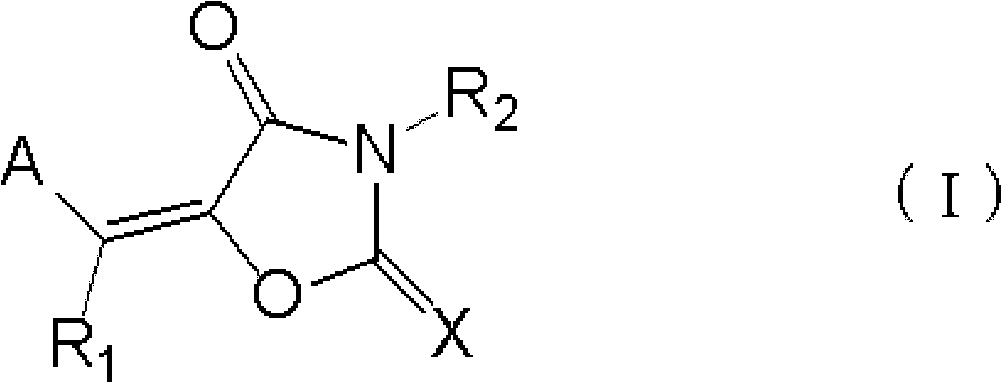

[0312]

[0313]

[0314] The compounds represented by their trade names in the above compositions are given below.

[0315] IRGACURE 250: (4-Methoxyphenyl)[4-(2-methylpropyl)phenyl]iodo Hexafluorophosphate

[0316] (75% by weight propylene carbonate solution)

[0317] SR-399: Dipentaerythritol Pentaacrylate

[0318] BYK 336: Modified dimethyl polysiloxane copolymer (25% by weight xylene / methoxypropyl acetate solution)

[0319] KLUCEL M: Hydroxypropylcellulose (2% by weight aqueous solution)

[0320] ELVACITE 4026: highly branc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com