Sealed structure of mini-type electronic dehumidifying and cooling machine

A technology of electronic dehumidifier and cooler, applied in the direction of cooling/ventilation of substation/switchgear, etc., can solve the problems of hidden danger of electrical safety, rising power consumption of dehumidification equipment, difficult exchange of cold and heat with large temperature difference, etc., to achieve reliability The effect of protection and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

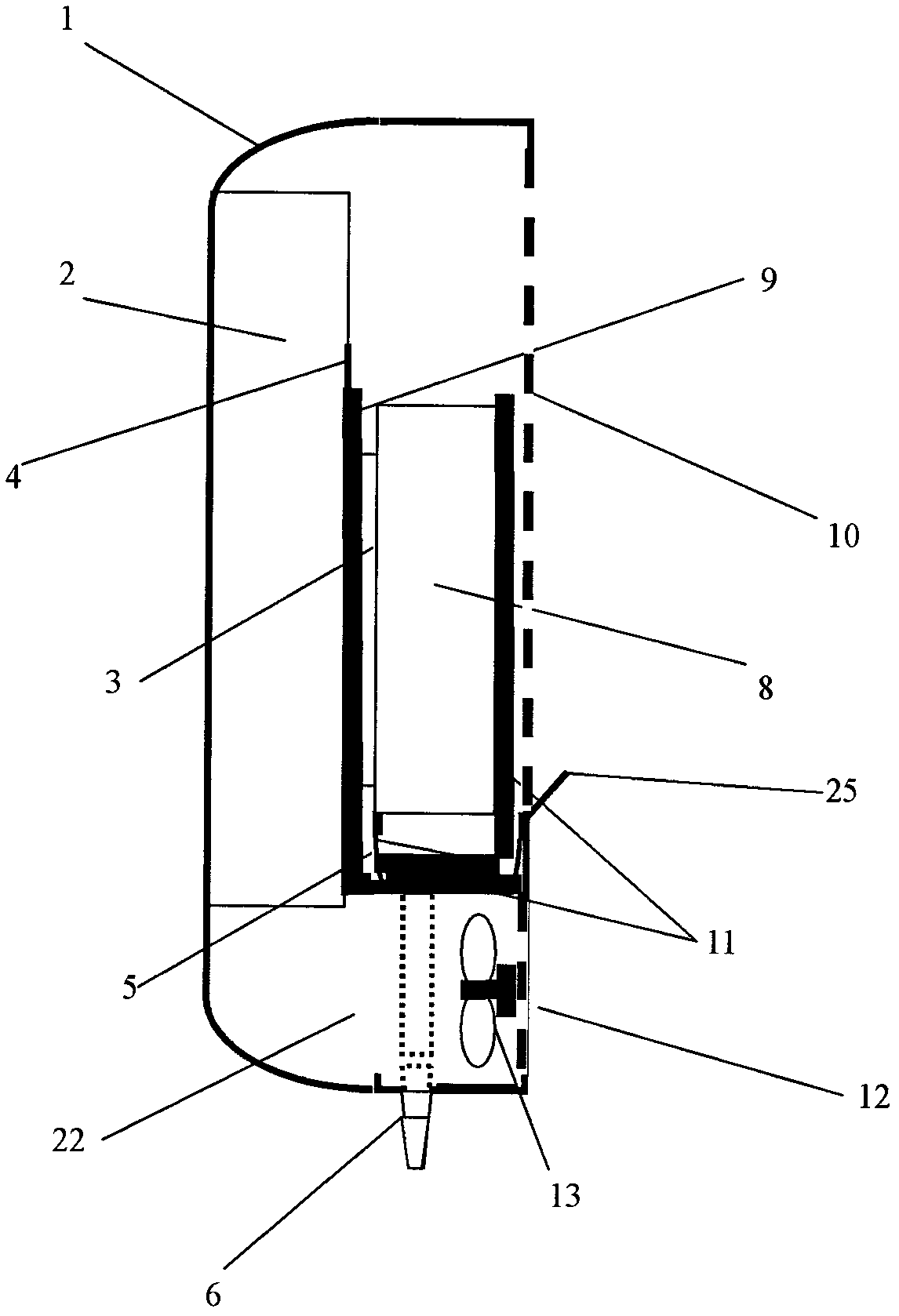

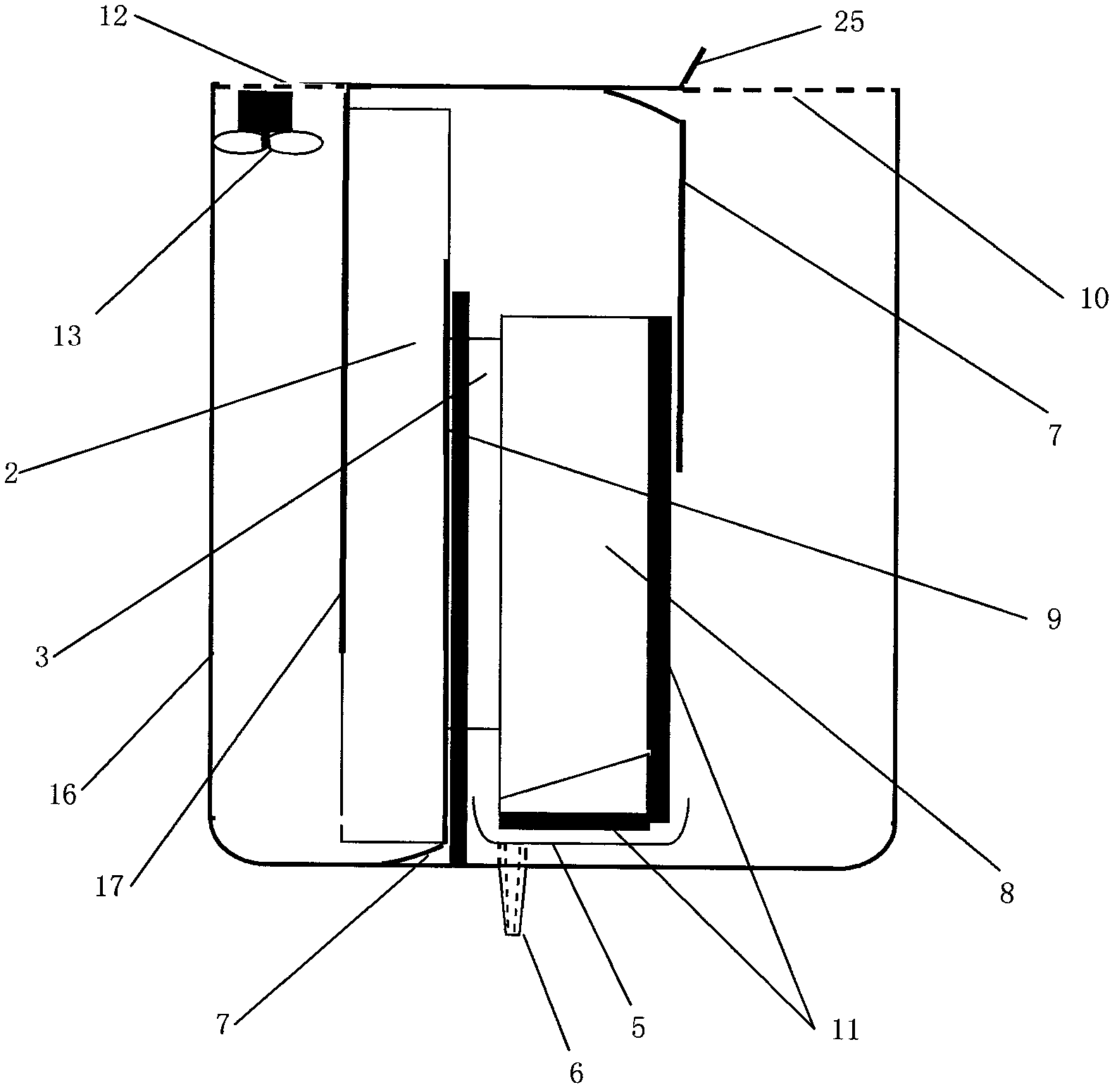

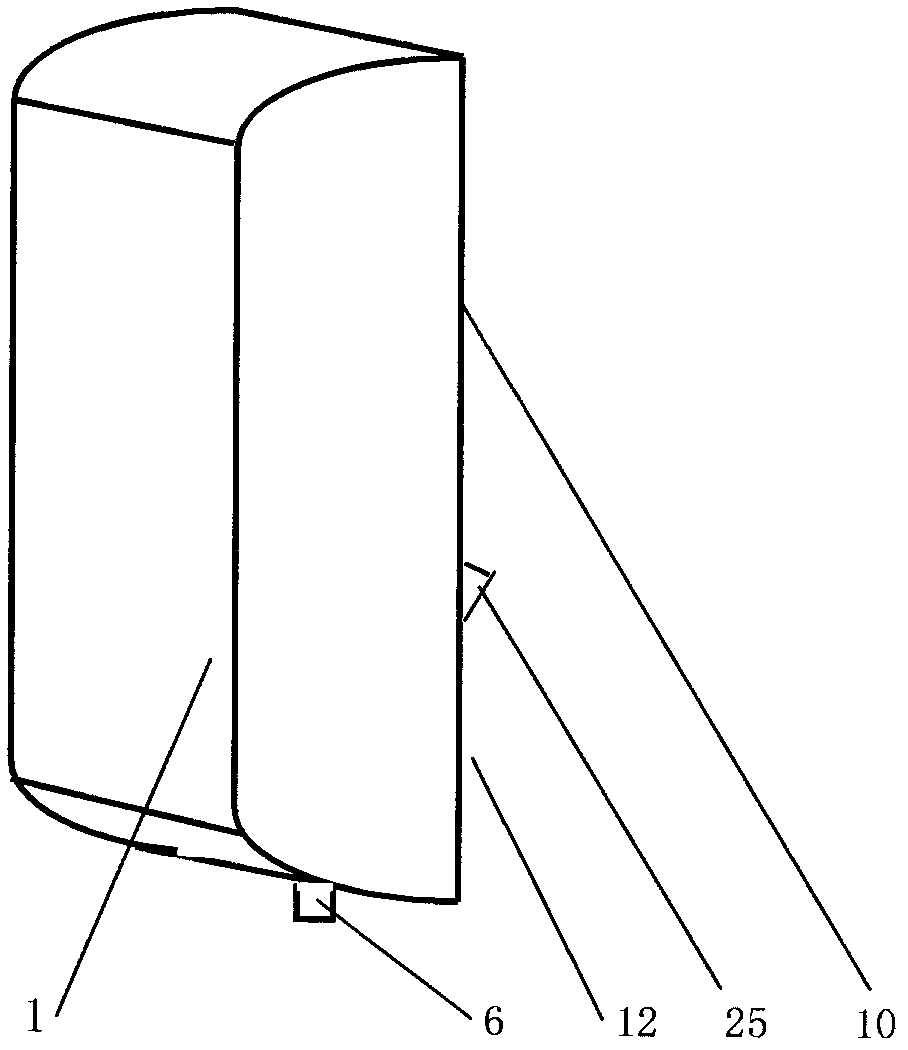

[0021] According to the installation position on the dehumidification and cooling equipment, the side of the equipment is divided into a miniature electronic dehumidification and cooling device and a miniature electronic dehumidification and cooling device is installed on the bottom panel of the equipment. Air inlet (12), 1 dry cold air outlet (10) and 1 dry cold air outlet deflector baffle (25), and a detachable box outer cover (1) is installed on the side, and there is a condensed water discharge pipe ( 6), the other parts of the miniature electronic dehumidification and cooling device (Figure 3) are completely closed, and the heat conduction paste is evenly coated on both sides of the upright electronic cooling plate (3), and the heat sink is square on the heating surface side of the electronic cooling plate Smooth backplane plane (14), the heating surface of the electronic cooling fin (3) is attached to the square smooth backplane plane (14) of the heat sink, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com