Curved display screen and method for manufacturing curved display screen

A technology of display screen and curved surface, applied in the field of display screen, can solve the problems of inappropriate buildings and small viewing angle of advertisement, and achieve the effect of expanding the viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

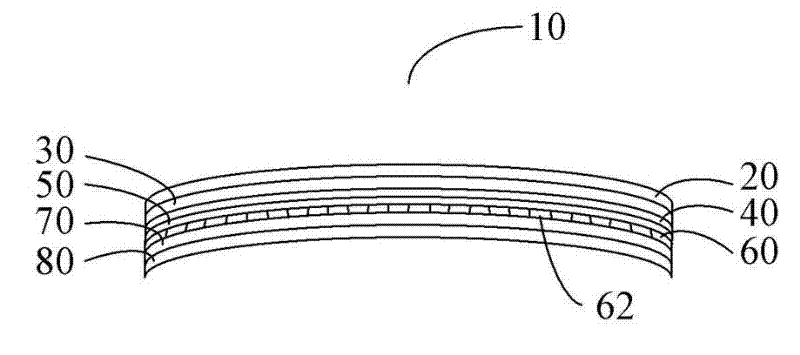

[0012] see figure 1 , is a schematic cross-sectional view of a curved display screen 10, including a front polarizer 20, a front glass plate 30, a color filter film 40, a liquid crystal layer 50, a thin film transistor matrix 60 composed of a plurality of thin film transistors (TFT) 62, and a rear glass plate 70 and rear polarizer 80.

[0013] The color filter film 40 , the liquid crystal layer 50 , and the TFT matrix 60 are packaged between the front glass plate 30 and the rear glass plate 70 , and the liquid crystal layer 50 is located between the color filter film 40 and the TFT matrix 60 . The front polarizer 20 and the rear polarizer 80 are attached to the outer sides of the front glass plate 30 and the rear glass plate 70 respectively.

[0014] The front glass plate 30, the rear glass plate 70, the front polarizer 20, and the rear polarizer 80 are all curved surface structures. Shaped by stretching. When the two glass plates are stretched, the area occupied by the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com