Hardened waterproof and oil-proof lens and manufacturing process thereof

A waterproof and oil-proof, manufacturing method technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of high processing cost, complicated process, and large power consumption, so as to reduce equipment investment cost, simplify process flow, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

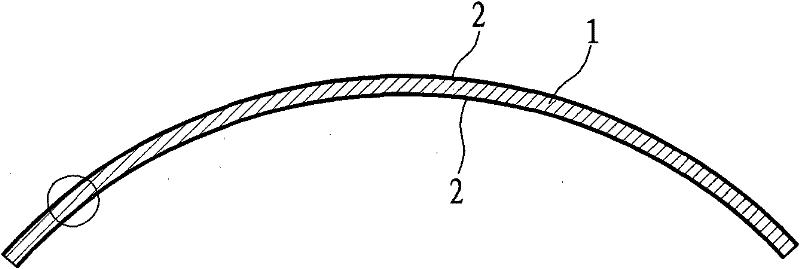

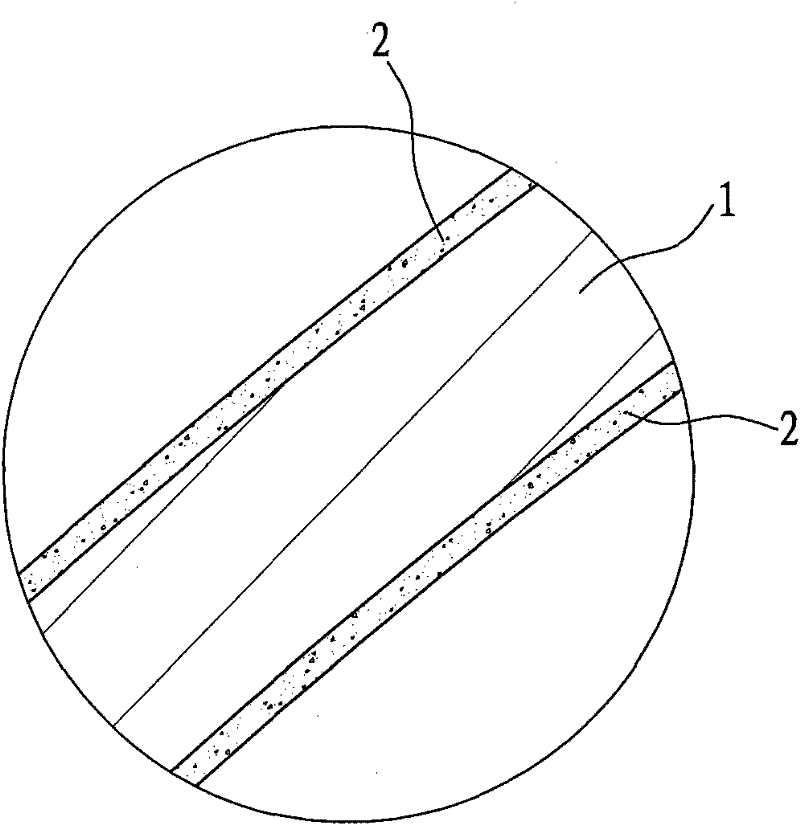

[0031] Such as figure 1 and figure 2 As shown, a hardened waterproof and oil-proof lens disclosed by the present invention is composed of a lens body 1 and a hardened waterproof and oil-proof film layer 2 . The lens body 1 can be TAC (triacetyl cellulose) lens, PCPL (polycarbonate polarized) lens, nylon lens, CR39 lens, glass lens, AC (acrylic) lens, PC (polycarbonate) lens or other resin lenses One of them, the shape can be a flat sheet or a curved lens, and the color can be a single color, a two-color progressive or a variety of electroplated colors. The hardened waterproof and oil-proof film layer 2 is attached to the inner surface and the outer surface of the lens body.

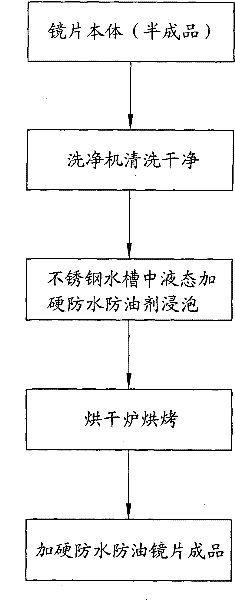

[0032] During the processing of the present invention, as image 3 As shown, the lens body 1 to be produced and processed is cleaned, using equipment: cleaning machine, and the cleaning process includes: cleaning liquid plus ultrasonic cleaning (50°C, 50 seconds) → ultrasonic cleaning (50°C, 50 second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com