Magnetic force microscopy probe with low magnetic moment and high coercive force and manufacturing method thereof

A magnetic force microscope, high coercivity technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of low and medium coercivity, low magnetic moment and high coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

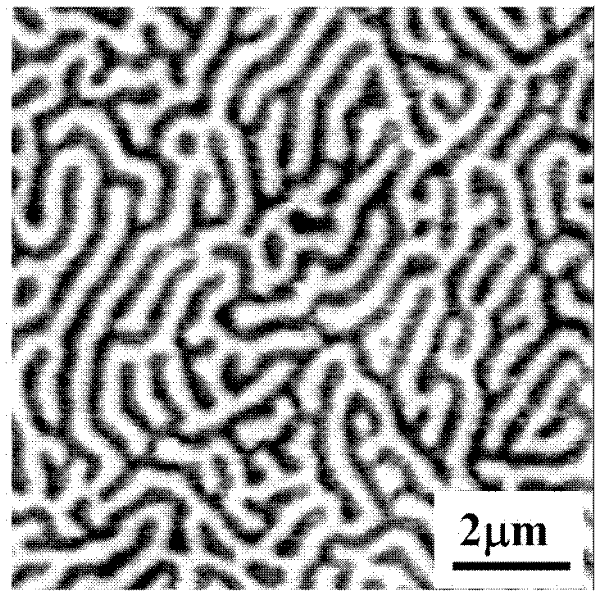

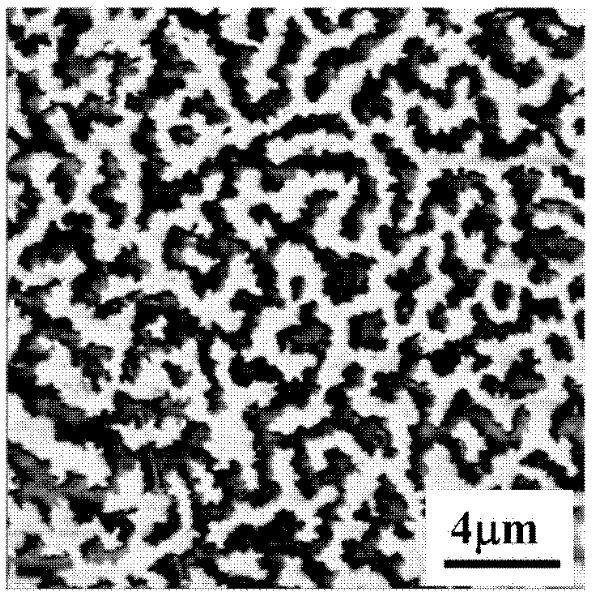

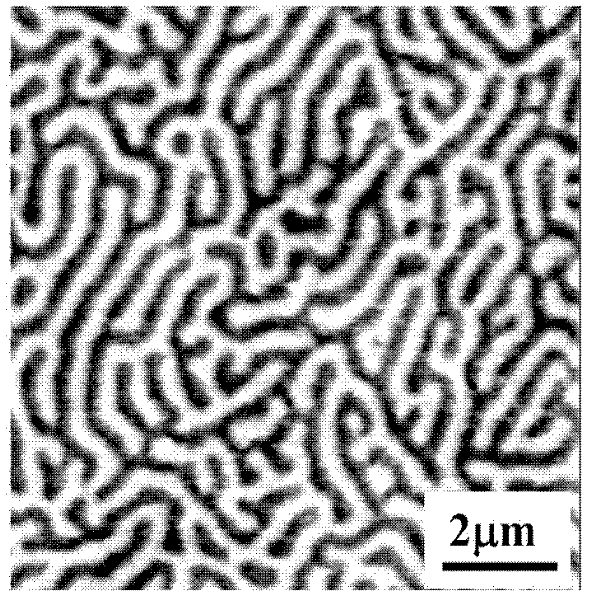

Image

Examples

Embodiment 1

[0028] The method for manufacturing the magnetic force microscope probe with low magnetic moment and high coercive force according to embodiment 1 comprises the following steps:

[0029] 1. Clean the Si probe with acetone or alcohol;

[0030] 2. Fix the above-mentioned Si probe after cleaning in the sample chamber of the magnetron sputtering apparatus, and evacuate the sample chamber. At this time, the vacuum of the sample chamber can be 1×10 -5 Below Pa, after that, high-purity inert gas is introduced to maintain the pressure of the sample chamber at 0.5 Pa;

[0031] 3. CoPt magnetic alloy (Pt atoms account for 45% of the total number of atoms in the CoPt alloy) is sputtered onto the surface of the above-mentioned Si probe by magnetron sputtering, the sputtering time is 15 minutes, and the sputtering power is 30 watts. Thereby obtaining a magnetic coating with a thickness of 30nm;

[0032] 4. Heat the obtained Si probe with magnetic coating to 500°C under high vacuum condit...

Embodiment 2

[0037]The method for manufacturing the magnetic force microscope probe with low magnetic moment and high coercive force according to embodiment 2 comprises the following steps:

[0038] 1. Clean the Si probe with acetone or alcohol;

[0039] 2. Fix the above-mentioned Si probe after cleaning in the sample chamber of the magnetron sputtering apparatus, and evacuate the sample chamber. At this time, the vacuum of the sample chamber can be 1×10 -5 Below Pa, after that, high-purity inert gas is introduced to maintain the pressure of the sample chamber at 0.3 Pa;

[0040] 3. CoPt magnetic alloy (Pt atoms account for 50% of the total number of atoms in the CoPt alloy) is sputtered onto the surface of the above-mentioned Si probe by magnetron sputtering, the sputtering time is 30 minutes, and the sputtering power is 5 watts. Thereby obtaining a magnetic coating with a thickness of 10nm;

[0041] 4. Heat the obtained Si probe with a magnetic coating to 650°C under high vacuum condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com