Detecting device for liquid flow of hollow turbine blade of combustion gas turbine

A technology for turbine blades and liquid flow, which is applied to mass flow measurement devices, direct mass flow meters, etc., can solve the problems of lack of accurate and reliable technical data, complicated operation, and loose sealing, etc., and achieves simple structure and simple processing. , Enhance the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

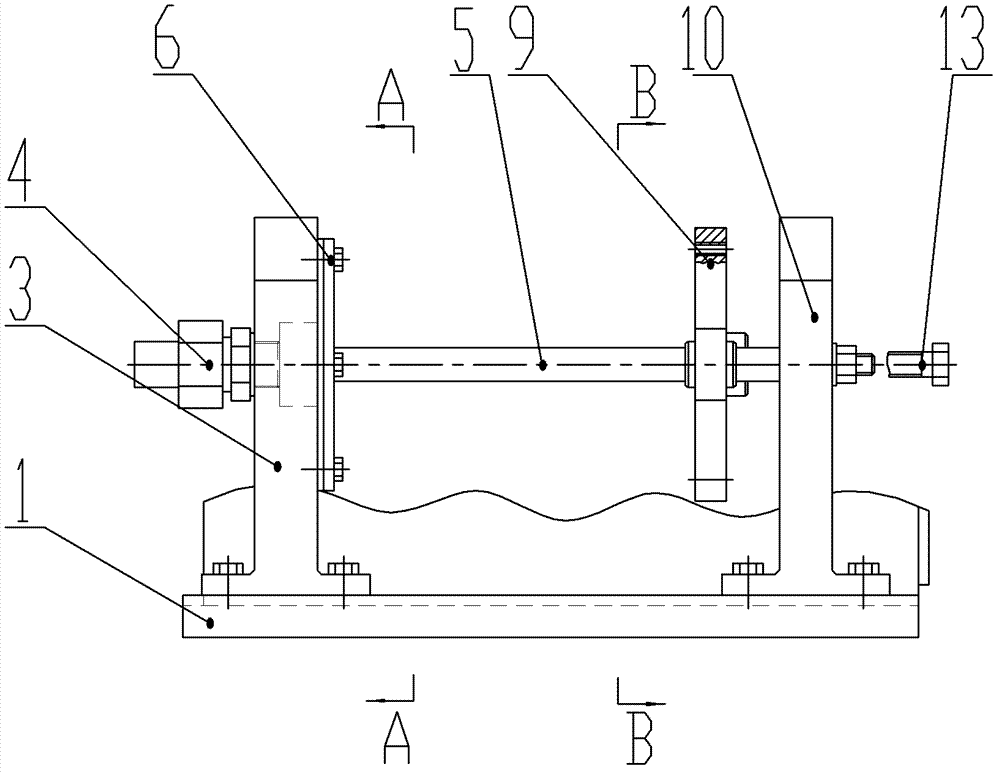

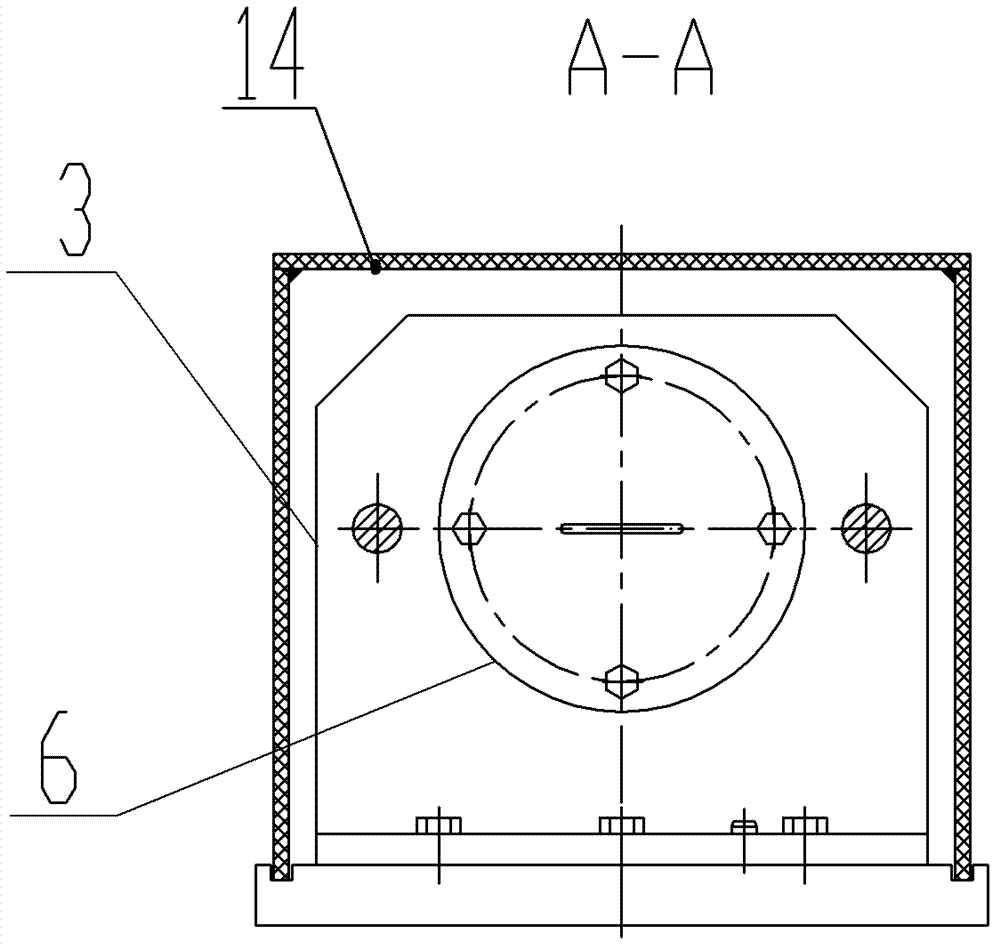

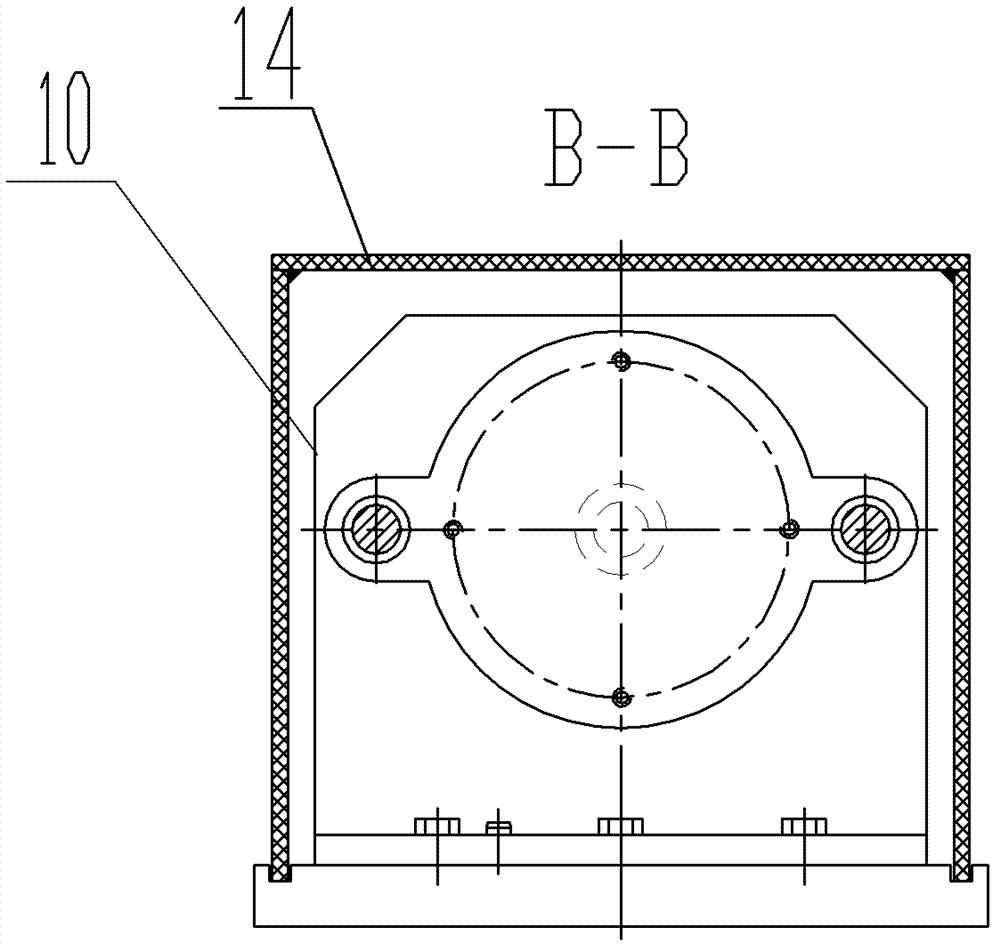

[0007] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the device of this embodiment includes a base 1, a left support 3, a straight-through pipe joint 4, a cover plate 6, a pressing plate 9, a right support 10, a jacking bolt 13 and a pair of guide rails 5, the base 1 is equipped with a left support 3 and a right support 10, the left support 3 and the right support 10 are arranged vertically, a pair of guide rails 5 are horizontally arranged between the left support 3 and the right support 10, and the pressing plate 9 is installed On a pair of guide rails 5 and slidingly connected with a pair of guide rails 5, a stepped through hole 3-1 is opened on the side wall of the left support 3, and one end of the straight-through pipe joint 4 is mounted on the left support 3 and communicated with the step. The hole 3-1 is connected, and the inner side wall of the left support 3 is equipped with a cover plate 6 and the two are detachably connected...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment, the device of this embodiment also includes a protective cover 14, a left support 3, a straight-through pipe joint 4, a cover plate 6, a pressing plate 9, a right support 10, a tightening bolt 13 and a pair of guide rails 5 All are arranged in the protective cover 14, and the upper end surface of the protective cover 14 and the base 1 is detachably connected, and this structure strictly prevents dust, cutting chips, hard sand grains, etc. from entering. Other implementation manners are the same as the specific implementation manner 1.

[0010] Working principle: The straight-through pipe joint 4 is connected with the liquid inlet system, the jacking bolt 13 is screwed out, and the pressure plate 9 is driven to stretch outward along the guide rail 5. At this time, the blade 17 is installed, and the blade root plug 11 is buckled on the blade On the blade root of 17, the blade root plug 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com