Vibration reduction and impact resistance method for spaceflight sensor

A technology of sensor and root mean square value, which is applied in the direction of the moving element of the damping part of the measuring device, can solve the problems of secondary collision, affecting stability requirements, affecting product performance, etc., and achieves the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

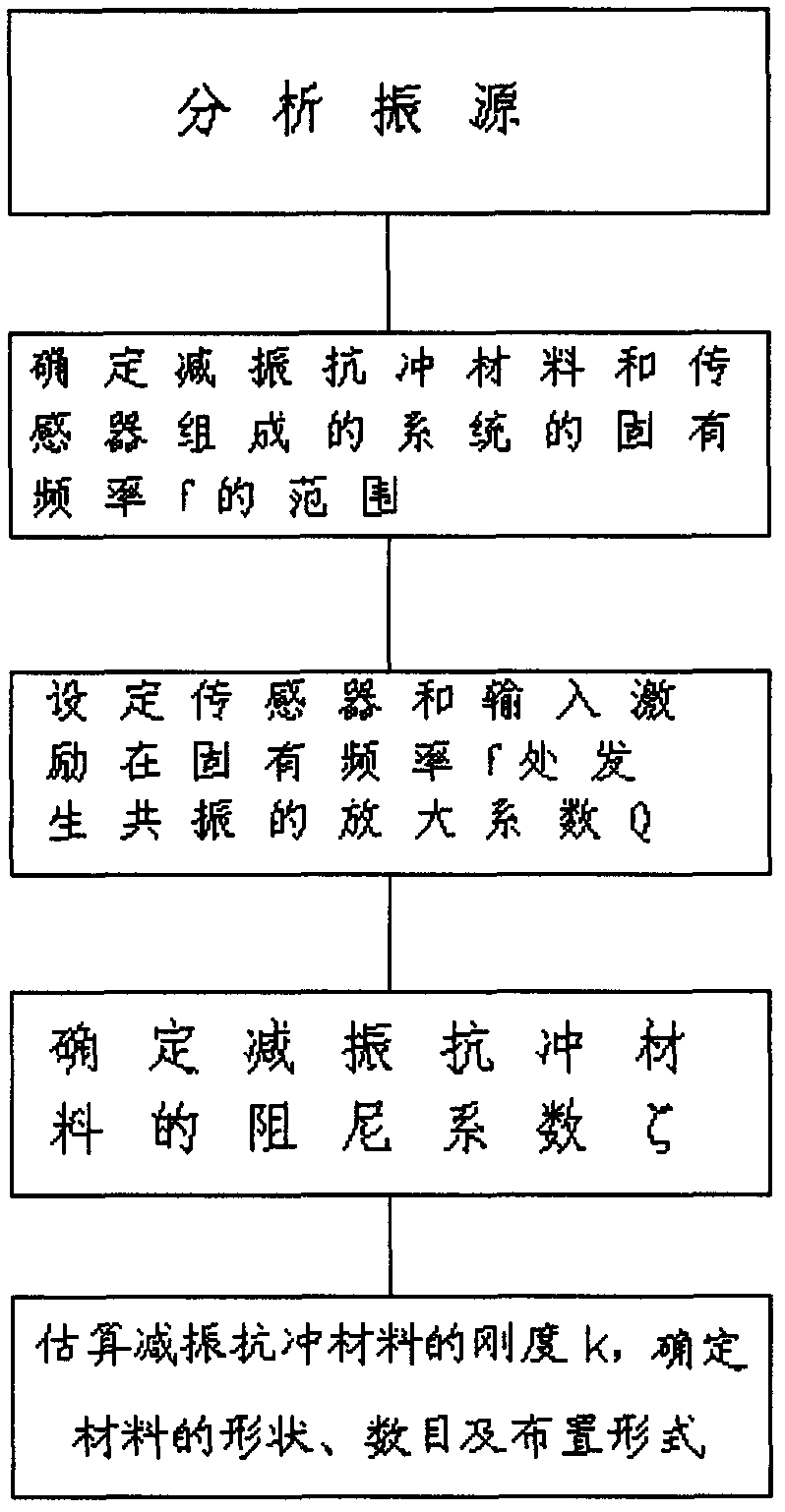

[0030] This embodiment is designed for the vibration reduction and anti-shock method of a certain aerospace sensor, and its flow chart is as follows figure 1 shown. Including analyzing the vibration source; determining the range of the natural frequency f of the system composed of the vibration-absorbing anti-shock material and the sensor; setting the amplification factor Q of the sensor and the input excitation resonating at the natural frequency f of the sensor; determining the damping of the vibration-absorbing and anti-shock material Coefficient ζ; and estimating the stiffness k of the vibration-damping and impact-resistant material through finite element analysis software; determining the shape, number and arrangement of the vibration-damping and impact-resistant material.

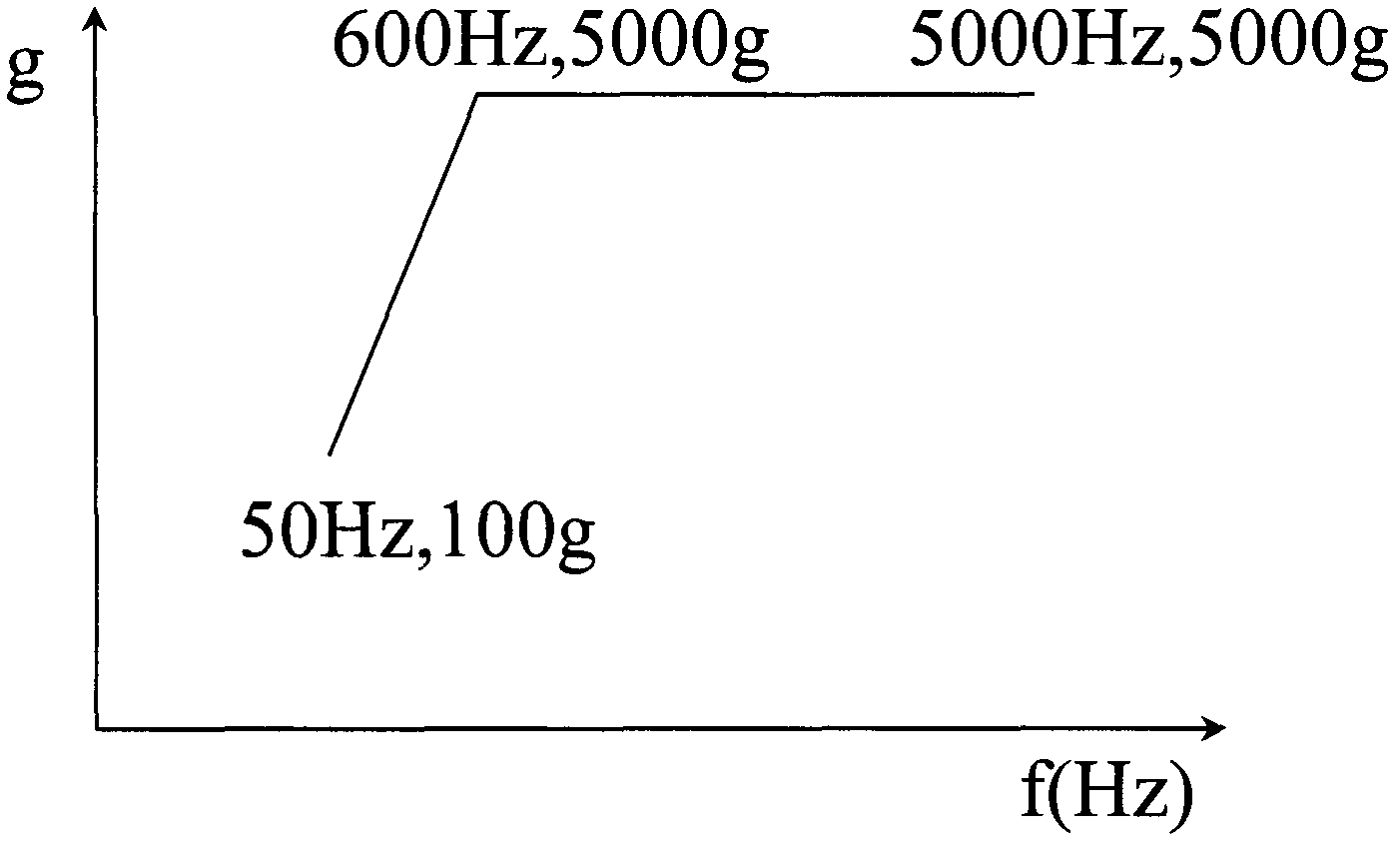

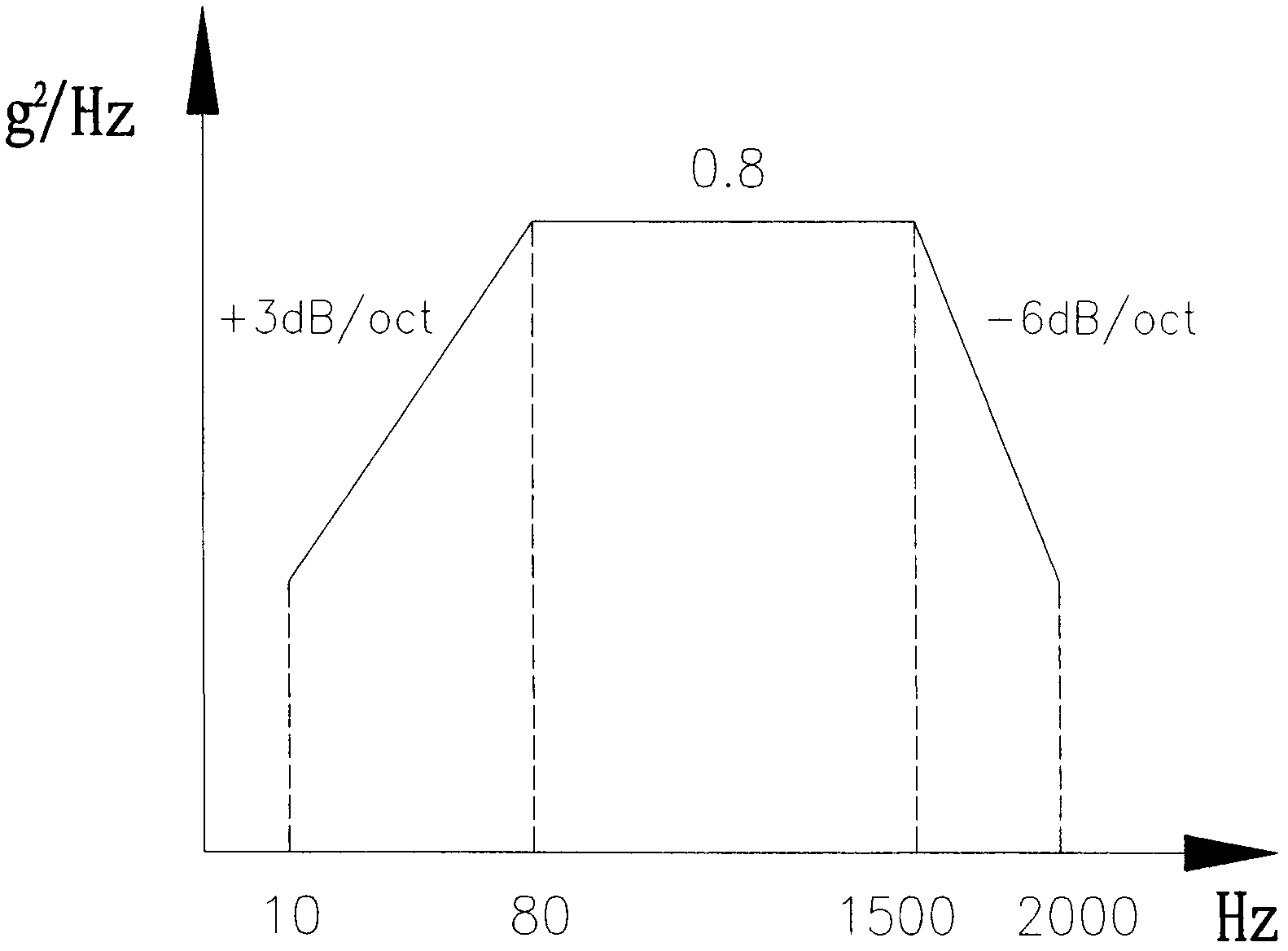

[0031] Such as figure 2 , 3 Shown is the shock test and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com