Top oxygen-blowing combustion system for intermediate frequency furnace

An intermediate frequency furnace and top-type technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of difficult control of finished product quality, impact on smelting cycle, long cycle of decarburizing agent, etc., to shorten the melting cycle and ensure the quality of steel tapping , the effect of uniform composition of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

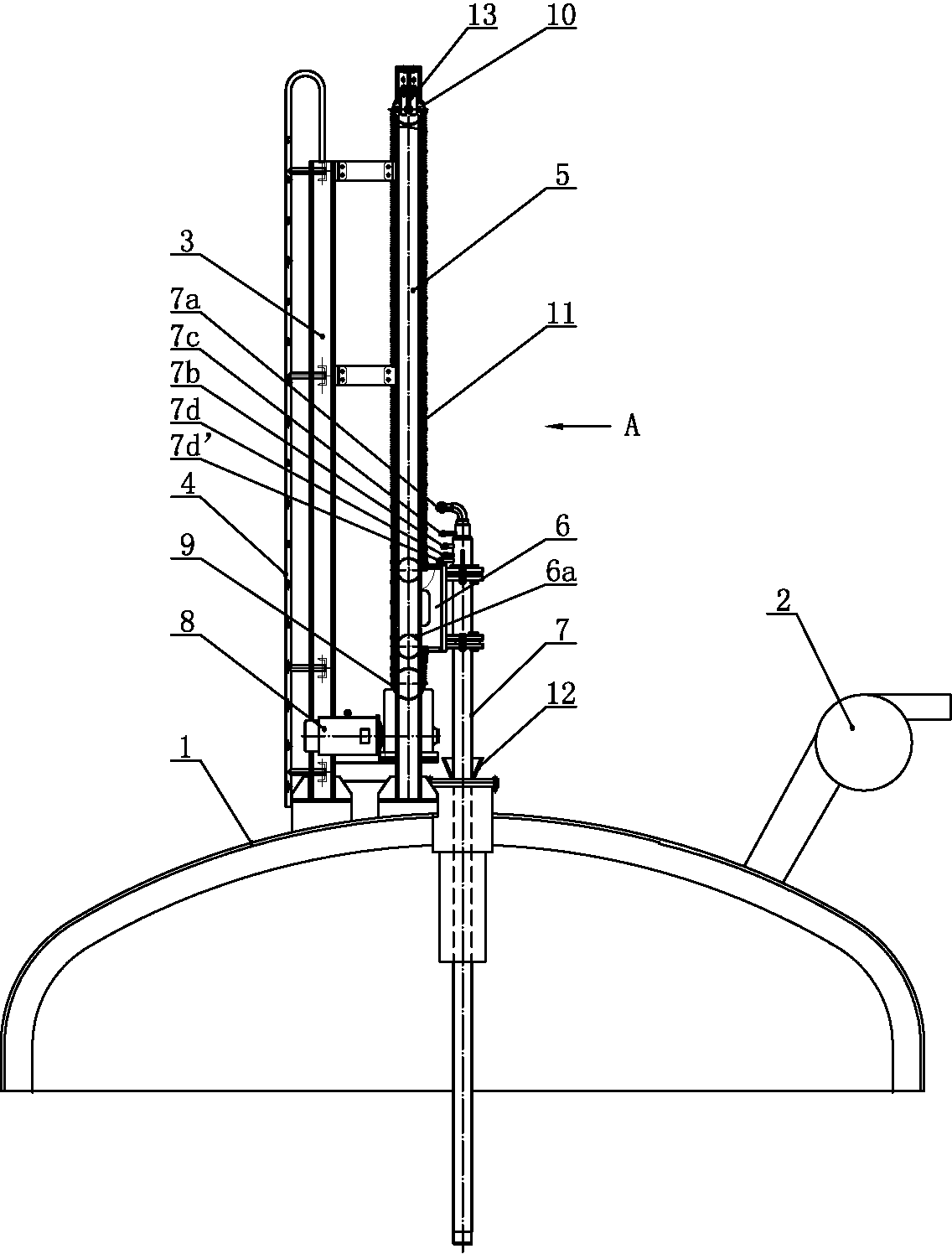

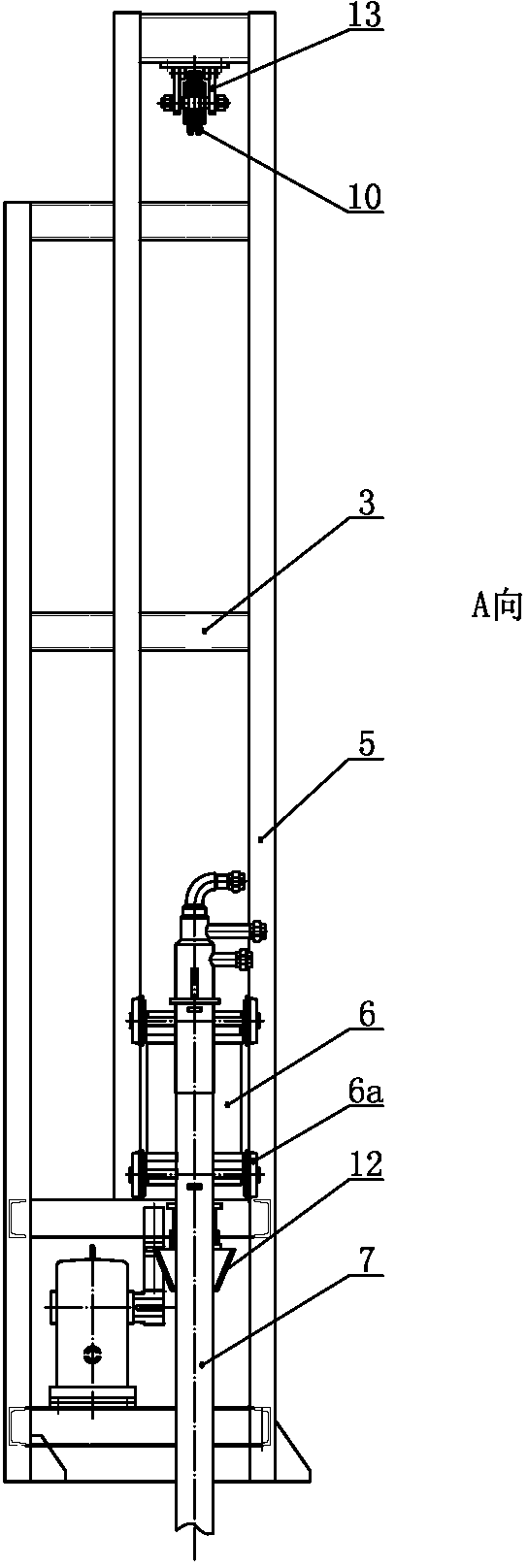

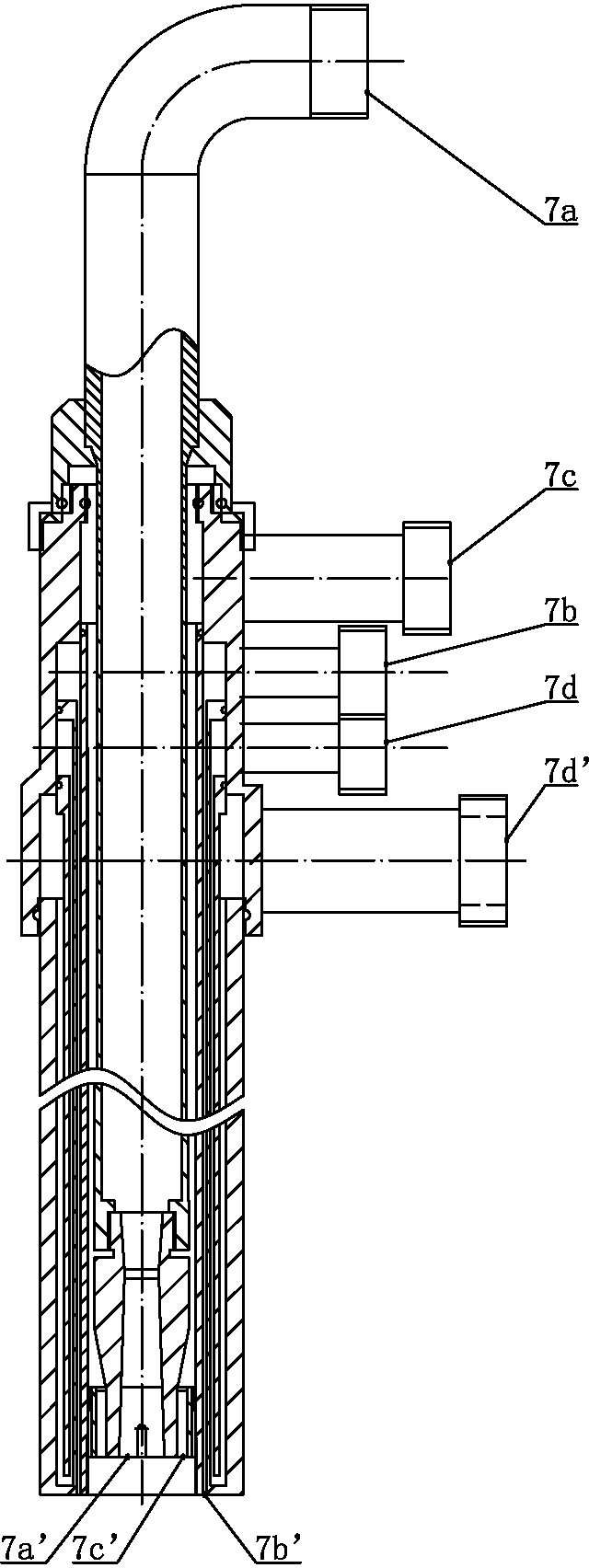

[0025] Such as figure 1 and figure 2 As shown, in the intermediate frequency furnace roof type oxygen-blowing system of the present invention, a furnace cover 1 is provided on the top of the intermediate frequency furnace, a fan 2, a bracket 3 and a ladder 4 are arranged above the furnace cover 1, and a vertical guide rail 5 and a lifting trolley are installed on the bracket 3 6. The lifting trolley 6 is supported on the vertical guide rail 5 by the roller 6a and can move up and down along the vertical guide rail. The upper end of the vertical guide rail 5 is equipped with an upper sprocket 10, and the lower end of the vertical guide rail is installed with a lower sprocket 9. The upper sprocket 10 and the lower sprocket The sprocket 9 is connected through the transmission of the chain 11, one end of the chain 11 is connected to the upper part of the lifting trolley, and the other end of the chain 11 is connected to the lower part of the lifting trolley; the intermediate frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com