Microwave vacuum drier

A microwave vacuum drying and microwave vacuum technology, which is applied in the direction of progressive dryers, dryers, and drying solid materials, can solve the problems of high labor intensity, high drying temperature of materials, and unfavorable microwave heating of dried materials, so as to improve Ergonomic and capacity-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

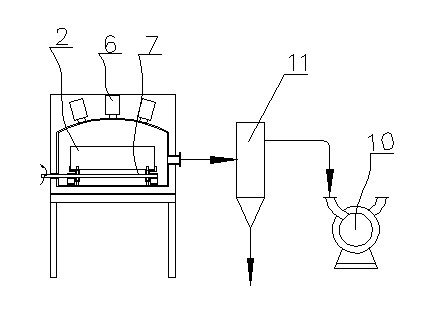

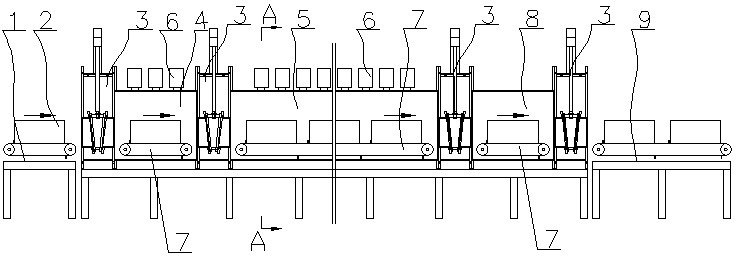

[0013] Such as figure 1 , figure 2 As shown, a microwave vacuum dryer includes a feed vacuum chamber 4, a microwave vacuum chamber 5, and a cooling discharge vacuum chamber 8 which are sequentially connected by a vacuum valve 3. The cross-section and length of each vacuum chamber are determined according to the designed drying capacity , The lower part of each vacuum chamber is provided with a stepping conveyor 7, and a vacuum valve 3 is provided at the front end of the feeding vacuum chamber 4 and the rear end of the cooling discharge vacuum chamber 8; microwave heating is provided on the upper wall of the microwave vacuum chamber 5 Device 6, (the setting of the microwave heating device 6 belongs to the prior art, and can be installed around the microwave vacuum chamber 5) is in a continuous working state during the drying process, and a microwave heating device 6 is also provided on the upper wall of the feed vacuum chamber 4 , The microwave heating device 6 on the upper wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com