Micro electromagnetic valve

A solenoid valve, a miniature technology, applied in the field of solenoid valves, can solve the problems of high noise and inability to rotate the coil, and achieve the effect of compact structure, good sealing performance, and free adjustment of the coil angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

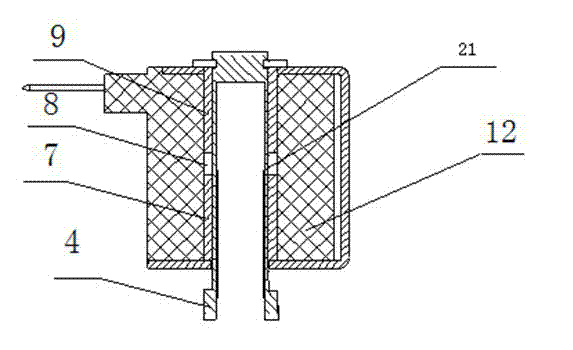

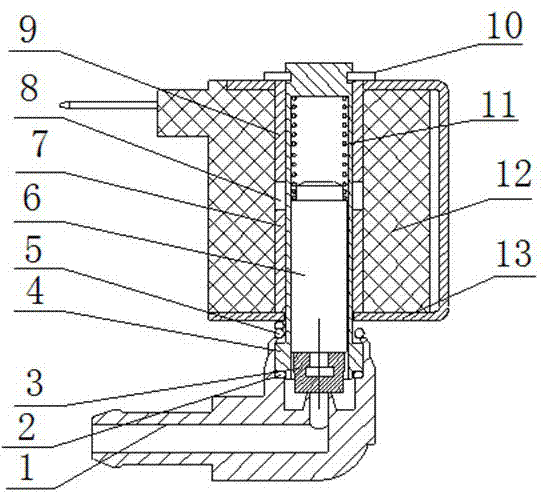

[0018] A miniature electromagnetic valve, comprising an electromagnetic coil 21, a valve body 1 and a magnetic isolation tube 4, a compression spring 5 is installed between the electromagnetic coil 21 and the valve body 1, the electromagnetic coil 21 also includes a magnetizer 9, a coil 12, and a magnetic sleeve 7 and the magnetic isolation sleeve 8, the magnetic isolation tube 4 is connected with the valve body 1 by riveting, and is sealed with the sealing ring 2.

[0019] A movable iron core 6 is installed inside the electromagnetic coil 21 .

[0020] The upper end of the movable iron core 6 is sleeved with a spring 11 , and the lower end is sleeved with a diaphragm 3 .

[0021] A magnetic isolation sleeve (8) is installed between the magnetic conductor (9) on the electromagnetic coil (21) and the magnetic sleeve (7), so that the movement effect of the movable iron core (6) in the magnetic isolation tube (4) is further improved , that is, the environment where a relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com