Self-locking and interlocking mechanism for shifting fork shafts of gearbox

A technology of interlocking mechanism and shift fork shaft, which is applied in the direction of mechanical equipment, components with teeth, belt/chain/gear, etc., can solve the problem of processing complex gearbox seals, etc., and achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

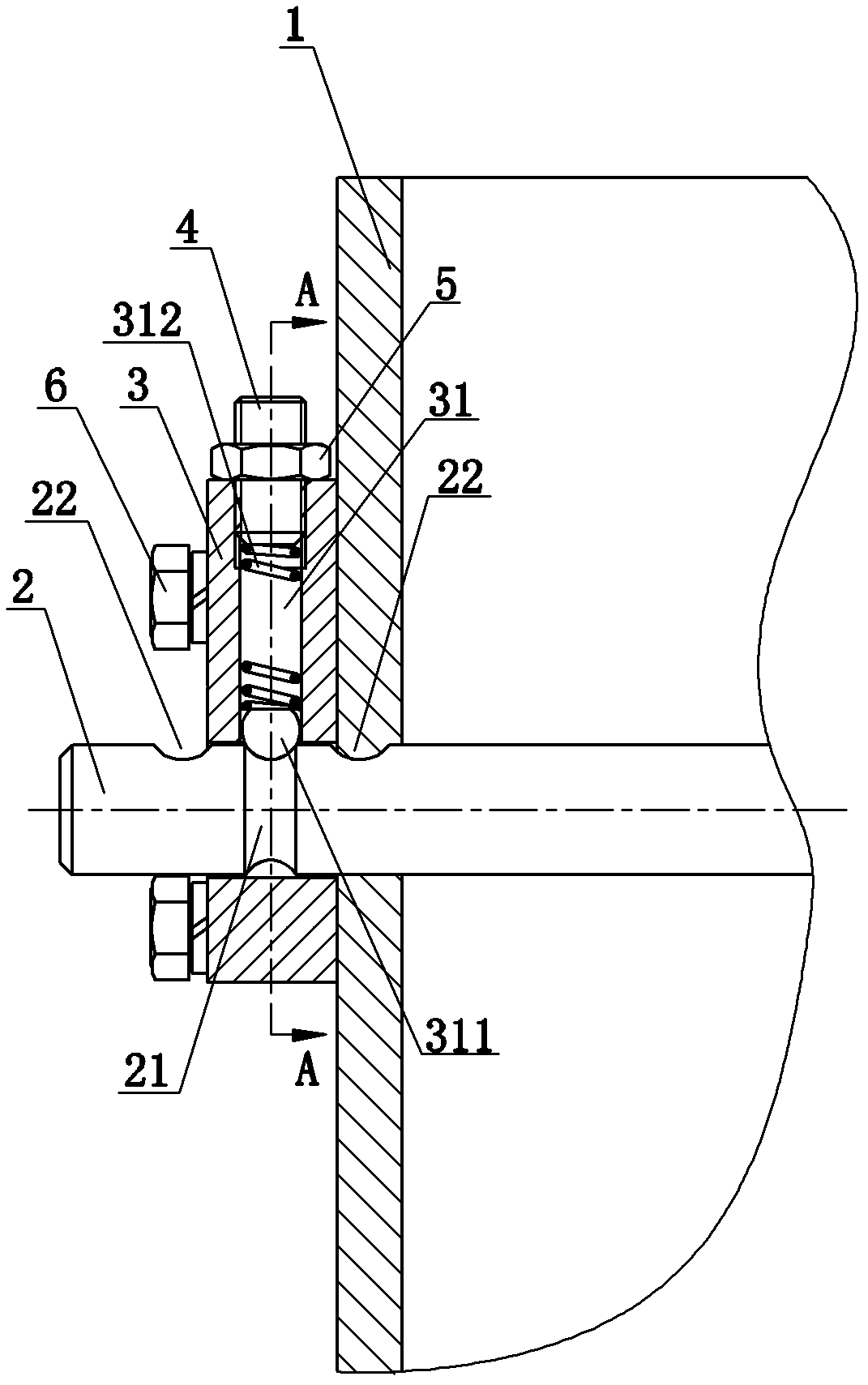

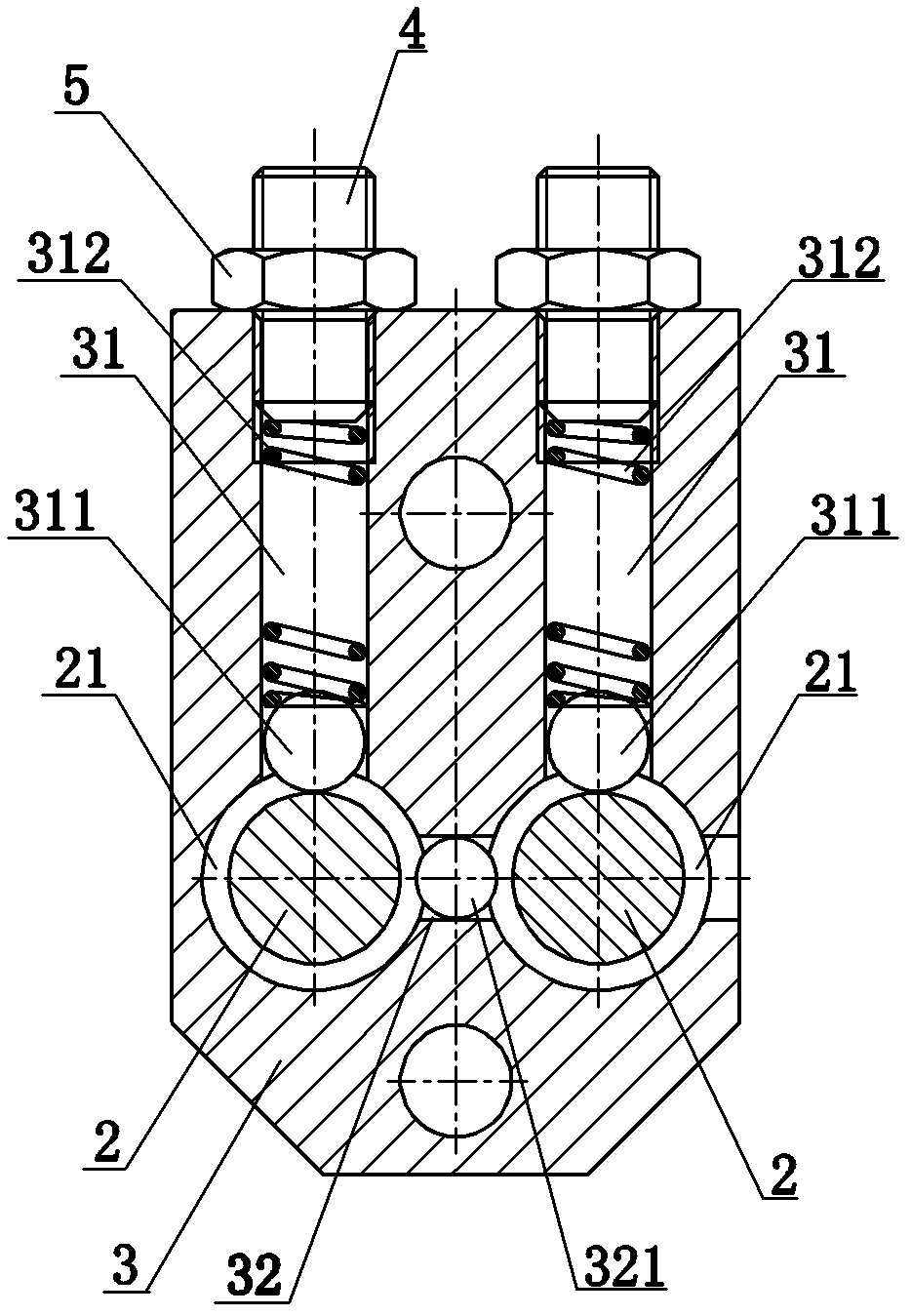

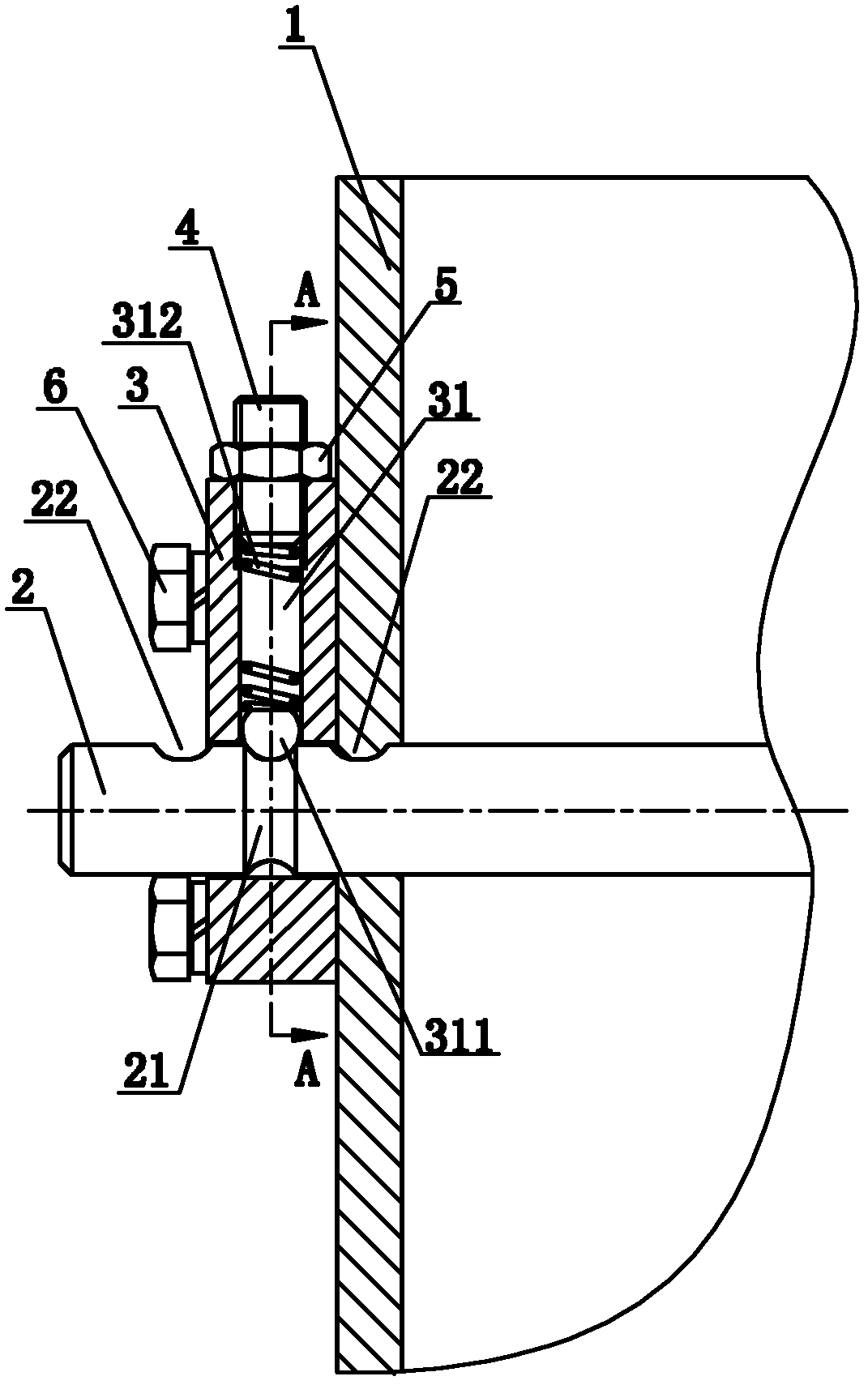

[0015] Such as figure 1 and figure 2 Commonly shown, the gearbox housing 1 passes through several shift fork shafts 2 in parallel, and the shift fork shafts 2 are respectively provided with neutral gear ring grooves 21, and the shift ring grooves 21 are located on both sides of the neutral gear ring grooves. The upper part of the fork shaft 2 has a self-locking groove 22. Of course, only two shift fork shafts 2 are shown in the figure to explain the present invention. When the gearbox includes multiple shift fork shafts, the principle is the same; The shift fork shaft 2 can move along its axial direction so as to complete operations such as gear shifting and gear shifting, which are well-known technologies in the technical field and will not be repeated here.

[0016] On the outer wall of the gearbox housing 1, a self-locking interlocking block 3 is fixed by a bolt 6, and the self-locking interlocking block 3 is provided with a shift fork shaft hole corresponding to the shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com