Radial air floatation guide module and photoetching machine motion platform applying same

A motion platform and air flotation-guided technology, which is applied in micro-lithography exposure equipment, mechanical equipment, photo-plate-making process exposure devices, etc., can solve the problems of the overall rigidity limitation of the motion platform, and achieve the effect of ensuring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

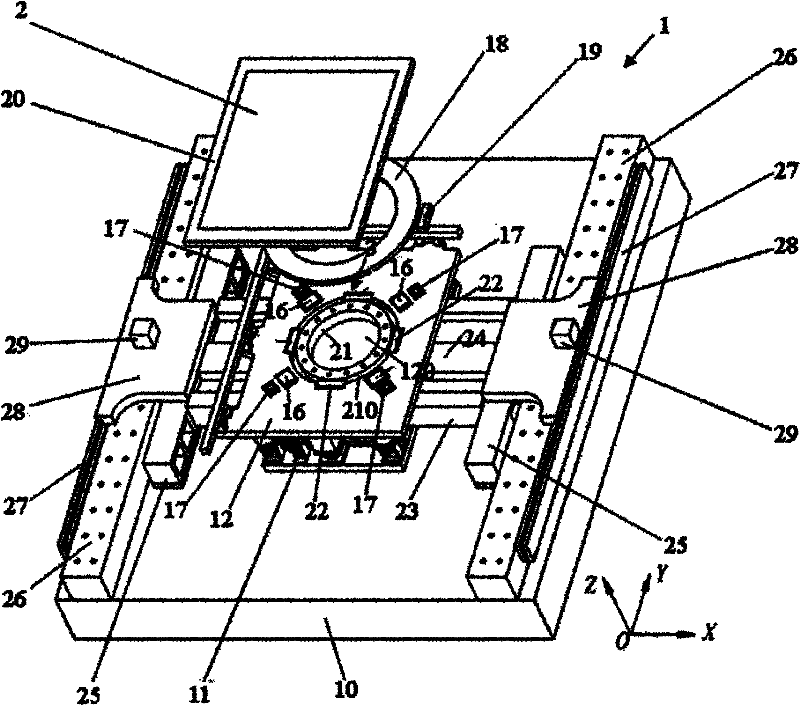

[0030] figure 1 Shown is a schematic diagram of a motion platform of a photolithography machine according to a preferred embodiment of the present invention. Please refer to figure 1 . In this embodiment, the motion platform 1 of the lithography machine is used to drive the workpiece 2 to move. The workpiece 2 can here be a silicon wafer. However, the present invention does not make any limitation thereto. In other embodiments, the workpiece 2 can also be a glass substrate.

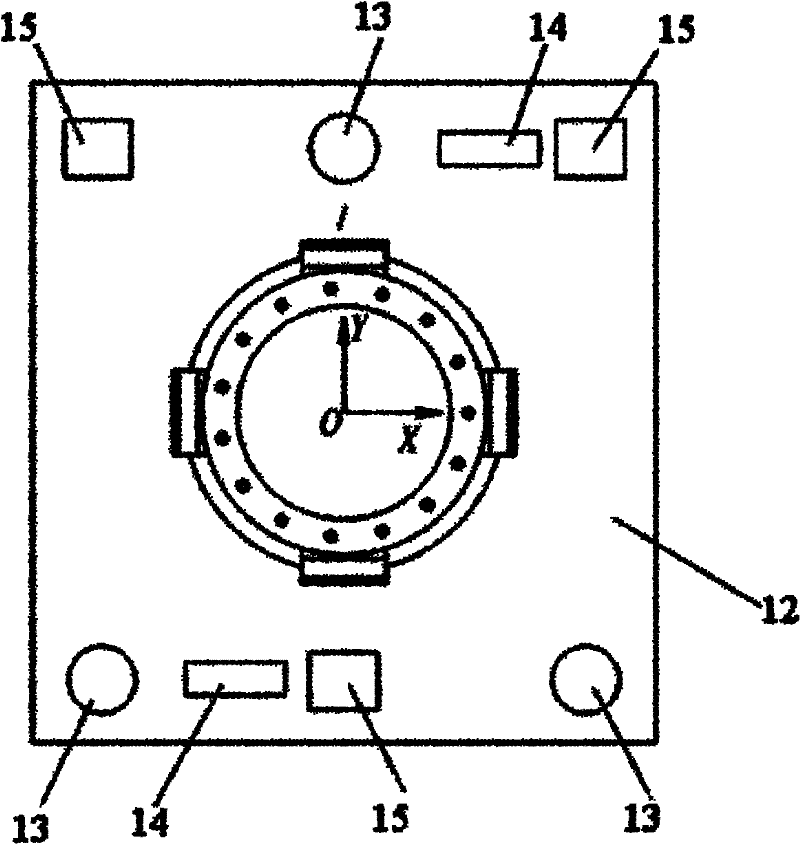

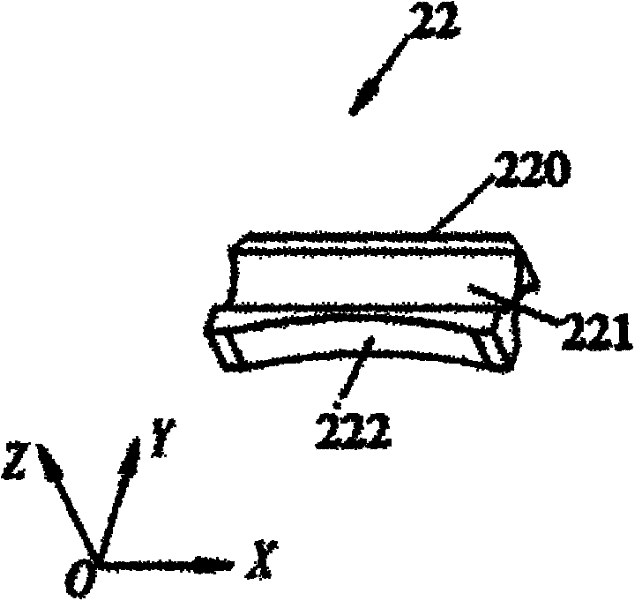

[0031] In this embodiment, the motion platform 1 of the lithography machine includes a base 10, a support 11, a micro-motion table 12, a Z-direction driving device, a gravity compensation unit 15, a vacuum block 16, an air floating block 17, and a coarse motion ring 18 , rotating motor 19, carrier 20, radial air bearing guide module 3, X guide rail 23, X guide linear motor 24, two air bearing slides 25, two Y guide guide rails 26, two Y guide linear motors 27, Two shuttles 28 and two displacement me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com