Multi-blade centrifugal fan with reinforced air inlet function

A centrifugal fan and multi-blade technology, which is applied to mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of increasing the circumferential speed of the impeller, and achieve the effects of increasing air volume, remarkable environmental protection effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

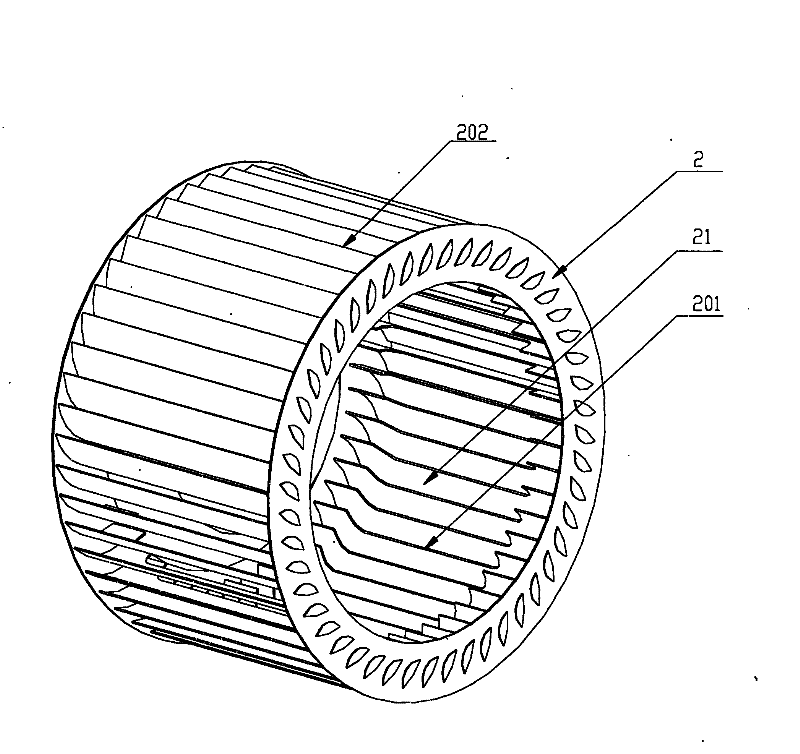

[0026] Such as figure 1 , figure 2 As shown, the multi-blade centrifugal fan with enhanced air intake function is composed of a fan main body 1 and a centrifugal impeller 2. The blades 21 are fixed on the impeller and are evenly distributed along the circumference. More specifically, the blades, the blades The intake side 201 is formed by straight lines and curves, and is concave; the exhaust side 202 of the blade is formed by straight lines.

Embodiment 2

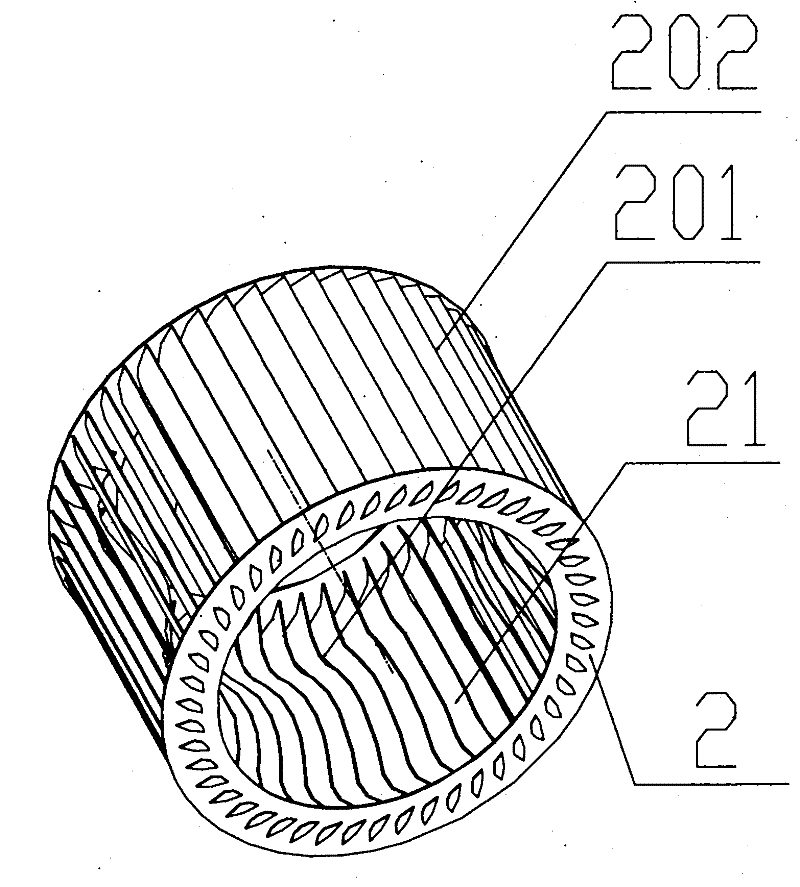

[0028] Such as image 3 As shown, the only difference between this embodiment and Embodiment 1 is that the inlet edge 201 of the blade is formed by a curve and is wavy.

Embodiment 3

[0030] Such as Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that the air inlet edge 201 of the blade is formed by a broken line and is in an "L" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com