Pneumatic and structural feature considered three-dimensional geometric structure of fan blade of aircraft engine

A technology with structural features and engines, applied in the direction of engine components, machines/engines, blade support elements, etc., can solve the problems of large flow separation loss, excessive stress at the root extension section, and difficulty in blade installation, so as to reduce the Mach number, Effects of improving efficiency and improving import conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

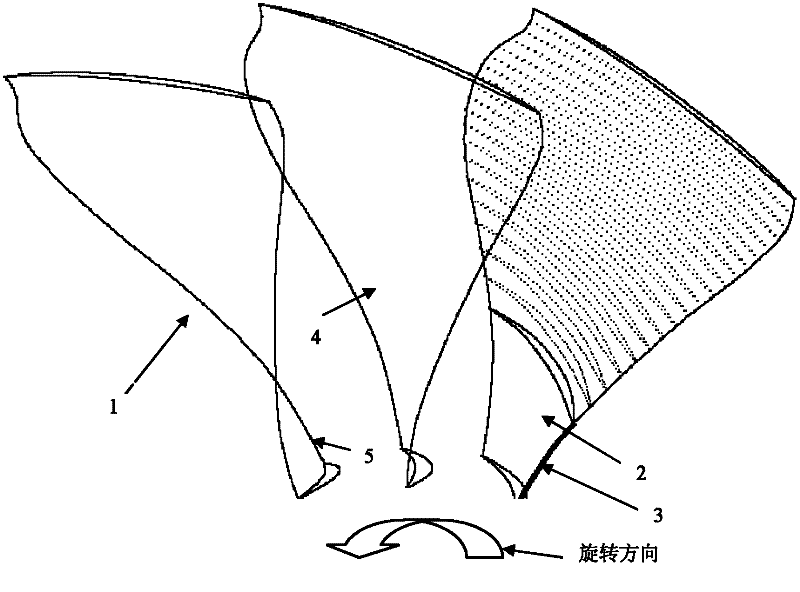

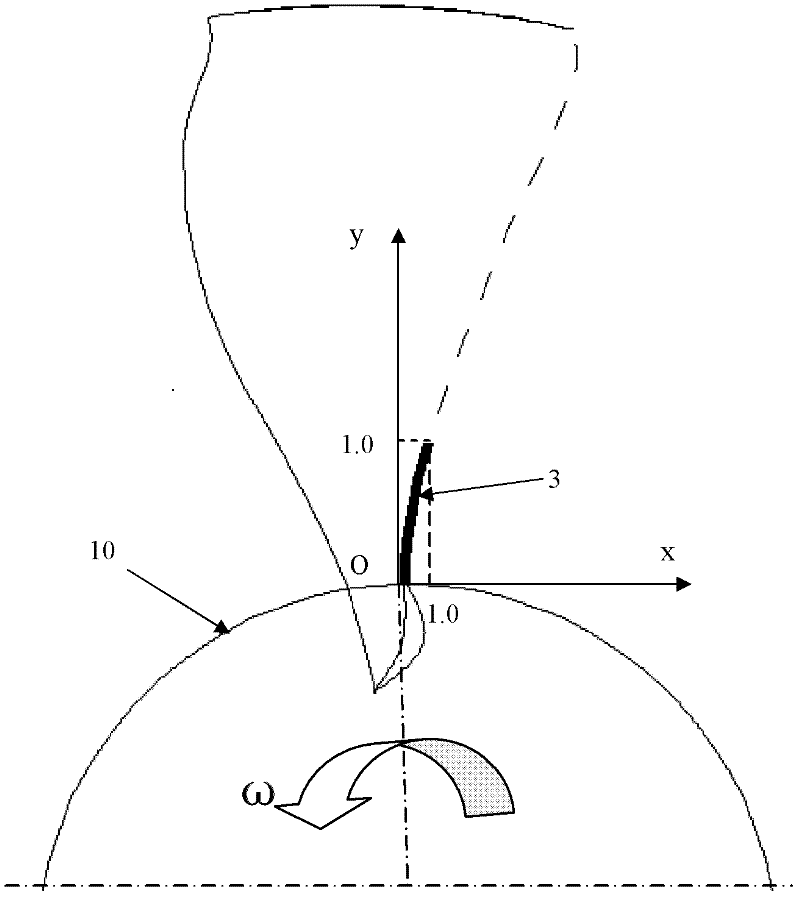

[0021] A three-dimensional geometric structure of the connotation blade of a large fan of a civil aeroengine taking into account both aerodynamic and structural features, wherein the connotation blade refers to the part of the blade height of 0-20% of the blade of the large fan, and is characterized in that:

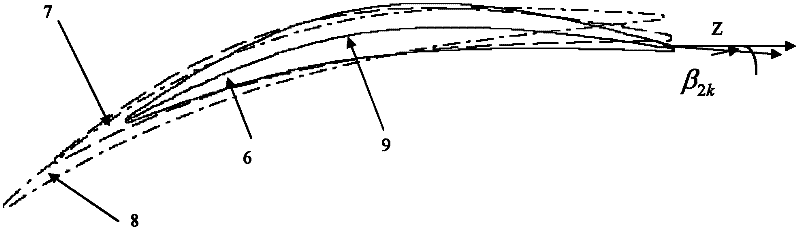

[0022] 1. Metal outlet angle β of connotative blade 2 primitive blade shape 2k (Such as figure 2 As shown, the tangent and axial direction of the center arc at the point of the trailing edge The included angle, clockwise is positive) The distribution along the spread can be described by a cubic polynomial

[0023] y=79.804x 3 +70.411x 2 +33.222x-8.62

[0024] Among them, x is the percentage of relative spread height, y is the metal outlet angle of the corresponding blade height primitive blade shape, the unit is degree (°), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com