Packer for intelligent well completion

An intelligent well completion and packer technology, applied in sealing/packing, wellbore/well components, earthwork drilling and production, etc., can solve the troublesome unsealing process, increase the unsealing force, and poor sealing performance and other problems, to achieve the effect of enhancing the sealing, reducing the lifting force and reducing the leakage point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

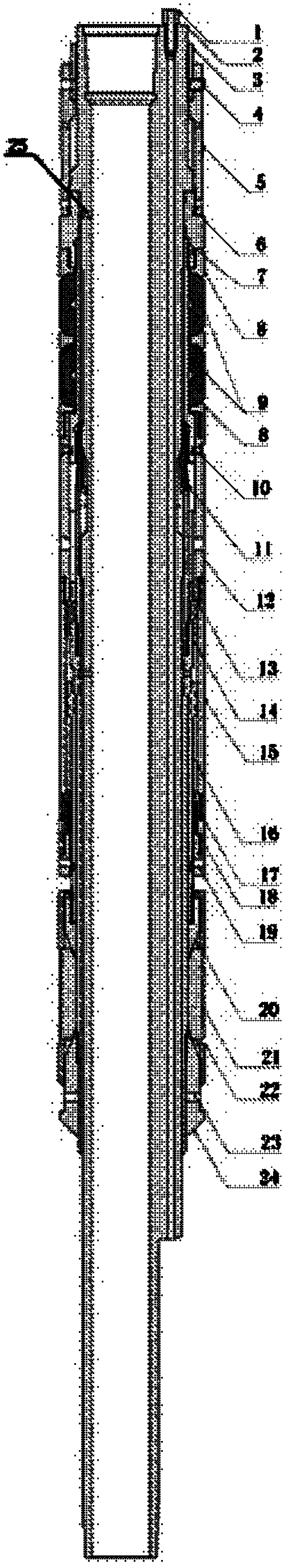

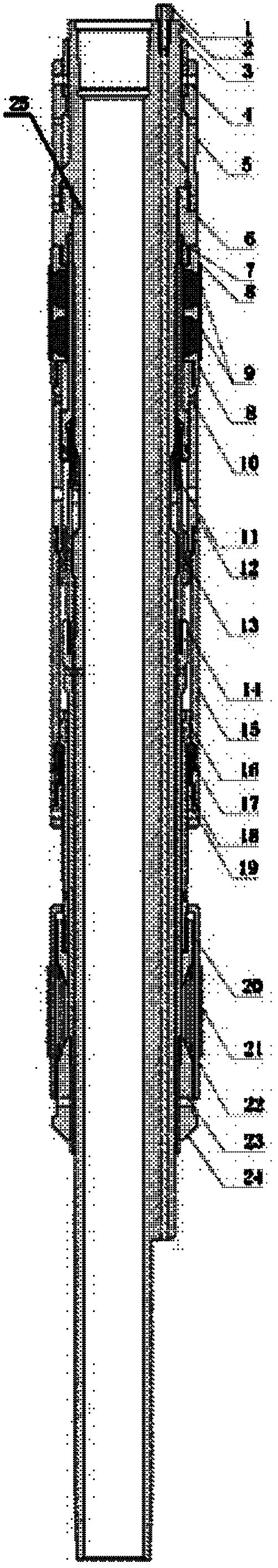

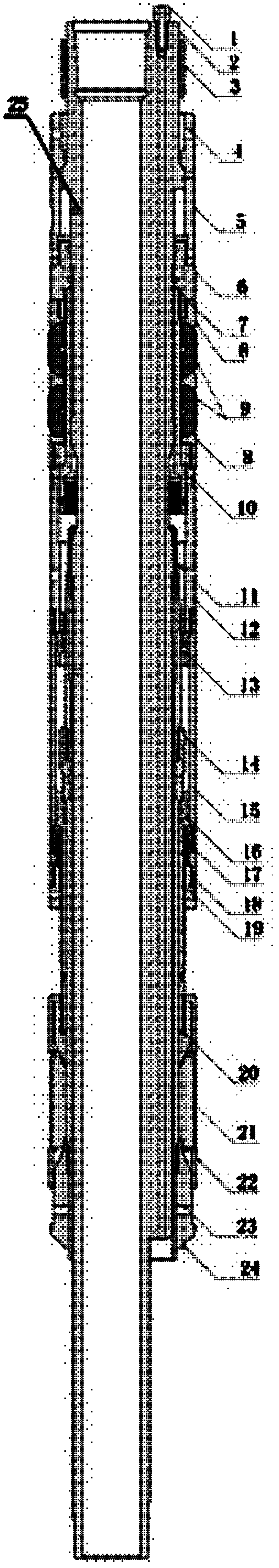

[0034] Please refer to figure 1 , Figure 4 , respectively are the structural schematic diagram and top view structural schematic diagram of the packer used for intelligent well completion of the present invention before entering the well. As shown in the figure, the packer for intelligent well completion proposed by the present invention includes a main body 2, and a rubber cartridge sealing mechanism for expansion setting and an anchoring mechanism are sleeved on the outside of the main body 2. The slip anchoring mechanism can play the role of setting seal. In the present invention, the main body 2 has an axially penetrating main channel 201 and a plurality of umbilical bypass channels 202 parallel to the main channel 201 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com