Coal-seam gas dual-channel well-washing valve

A dual-channel, coalbed methane technology, applied in the direction of flushing boreholes, boreholes/well components, earthwork drilling and mining, etc., can solve problems such as pulverized coal clogging and inspection of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

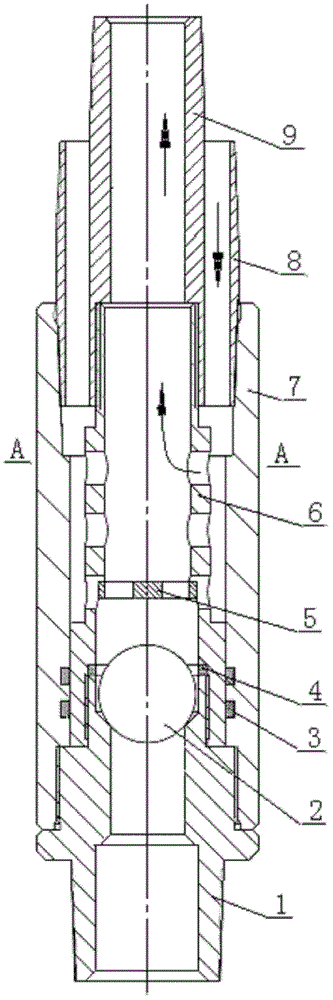

[0017] Embodiment 1: Taking a coalbed methane dual-channel well flushing valve as an example, the present invention will be further described in detail.

[0018] refer to figure 1 . The coalbed methane double-channel well flushing valve of the present invention includes a conversion joint 1, a steel ball 2, a sealing ring 3, a sealing gasket 4, a ball baffle 5, a core cylinder 6, an outer cylinder 7, and a pipe joint 8 with external threads at both ends. and drain pipe 9.

[0019] The conversion joint 1 has a central hole, and the lower end of the conversion joint 1 has a 73 mm flat API tubing external thread, and the lower end of the conversion joint 1 can be connected to a tubing string. The upper end of the adapter 1 has two external threads with different nominal diameters, and the two external threads with different nominal diameters are distributed in steps. Wherein, the nominal diameter of one external thread at the upper end of the conversion joint 1 is 90 mm; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com